A common application of NIR spectroscopy is the identification of the active compound or active pharmaceutical ingredient (API) present in a tablet or drug.

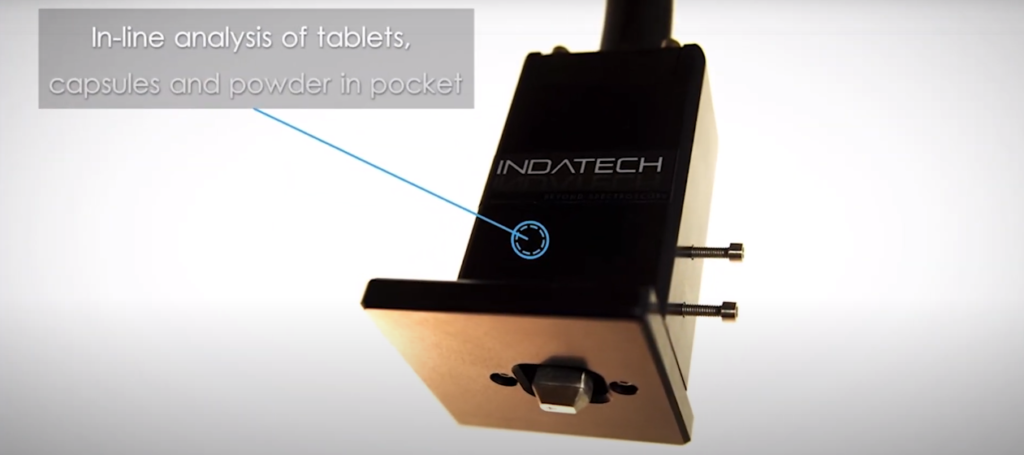

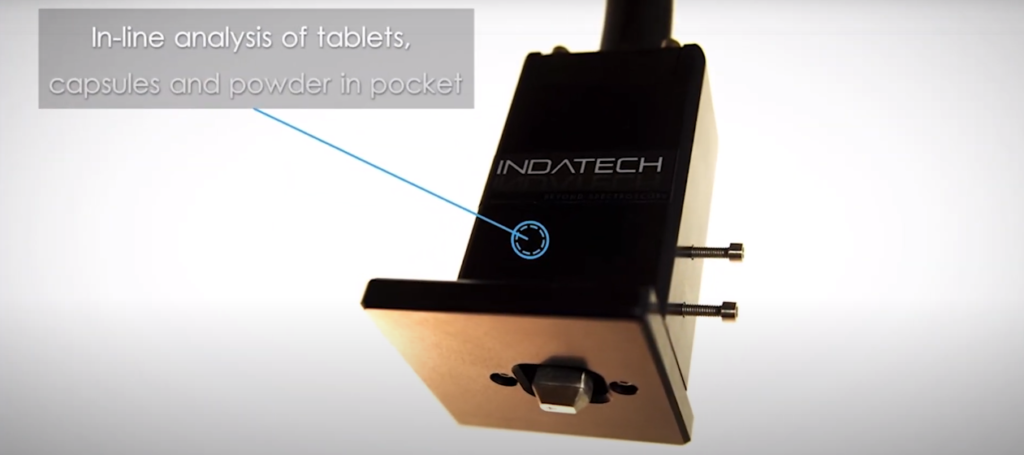

A French company, Indatech has developed a new technology for powder and tablet analysis that relies on the innovative use of optical probes using several optical fibres to measure the surface of the sample. All the fibres are connected to a Specim NIR hyperspectral imaging system.

About Indatech

Indatech was found in 2009 by Sylvie Roussel and Fabien Chauchard. Two main reasons were that Sylvie had found out that single spectra couldn’t provide the critical information that the customer needed while Fabien had been developing a solution, based on a multipoint imaging with promising results. This convinced them that hyperspectral imaging would be the best in-line technology in the future.

Currently Indatech provides solutions mainly for the pharma, biotech and chemical industry. Their core business is the high-speed inspection of a tablet (hardness, API, homogeneity) and powder either in manufacturing or in process development phase.

800,000

Number of analysed tablets per hour

Challenging approach meets hyperspectral imaging

The challenge in their approach is the need to measure multiple optical fibres at the same time as well as they must be able to change the configuration of the measurement. “Before hyperspectral, we tested standard spectrometer connected to an optical multiplexer but in the end, the measurement took too long,” says Fabien. “So, we decided to try the hyperspectral imaging and we found out that the pushbroom imaging is the best approach because the spectra are measured in a single shot without any moving parts and the resolution can also be adapted.”

“We started discussing with another manufacturer before we met Mr Timo Hyvärinen at a Pharma Congress in the United States. He presented me the company, as well as the technology behind it, and I’ve been completely convinced of the performance and the quality ever since. Specim is very reactive and always tries to find a solution in case of a specific need. The products are robust since the company has acquired a long experience. The products have the little things that make the difference in terms of performance and quality.” says Fabien.

Real partnership is a foundation for excellent results

“Our solution is now compatible with manufacturing machine speeds, we have been able to inspect from 150 000 to 800 000 tablets per hour based on homogeneity and API concentration. Specim’s reactivity, quality and flexibility both on delivering the camera and with technical support has met our expectations. We have been able to build a real partnership where our engineers can easily communicate with Specim engineers. This has resulted in continuous improvement in the use of the technology. We have modified the design of our solution based on hyperspectral camera in order to be able to work on different problematics using the same detector such as mixing of powder and fluid, compaction of the tablet, capsule filling, lyophilisation and so on.”

Want to know more?

Contact Luke Nicholls, Camera Sales Engineer, QDUKI