- Features

- Models

- Options

- Videos

- Downloads

- Applications

- Related Products

- Contact

- Back To Spectroscopy

- Back To Optics

- Back To Hyperspectral

- Back To Cameras

- Back To X-Ray

- Back To Light Measurement

- Back To Characterisation

- Back To Electron Microscopy

- Back To Magnetometry

- Back To Ellipsometers

- Back To Cryogenics

- Back To Lake Shore

InfraTec Image IR Series Thermography Cameras

High-speed thermography systems Precise radiometric calibration

The 2D infrared (IR) cameras from InfraTec are suitable for all applications of thermography. By using an IR camera one can perform non-contact absolute (or relative) temperature measurements, which allows – for example – non-destructive object inspection.

The ImageIR product line is particularly suitable for high-end research and development, non-destructive material testing and process monitoring. Plus, the modern thermography software family IRBIS ® 3 developed in-house by InfraTec is the ideal tool for fast analysis of thermography measurement data.

FEATURES:

- Excellent thermal resolution

- Easy to Use IRBIS3® Analysis-Software

- Very high frame rate

- Modular design for individual system expansion

- Long-life Stirling cooler for continuous operation

- Robust light-weight metal housing

- Accurate and repeatable triggering

- Complete optical assortment

MODELS

ImageIR® 8300 hs – The Fast

High-speed thermography with full resolution

- Detection of small details by detector with (640 × 512) IR pixels

- High thermal resolution of better than 20 mK for precision measurements

- High frame rate of 1,004 Hz enables thermographic images of extremely fast moving objects or highly dynamic thermal processes

- Pixel pitch of 25 µm allows shortest integration times and extremely high frame rates

ImageIR® 8100

High-resolution, radiometrically calibrated infrared cameras with a very good price/performance ratio – these are the new SWIR cameras from the ImageIR® series. They are suitable for temperature measurements from 300 °C and operate in the short-wave infrared range.

- Cooled focal plane array photon detector operating in snapshot mode with (640 × 512) IR pixels

- Cost-effective, compact optics design with high imaging quality

- The compact design and low weight predestine the SWIR thermal imaging camera for integration into existing system environments

- The accompanying Software Development Kit (SDK) provides easy access to all camera functions

ImageIR® 9100

High-resolution, radiometrically calibrated infrared cameras with a very good price/performance ratio – these are the new SWIR cameras from the ImageIR® series. They are suitable for temperature measurements from 300 °C and operate in the short-wave infrared range.

- Cooled focal plane array photon detector operating in snapshot mode with (1,280 x 1,024) IR pixels

- Cost-effective, compact optics design with high imaging quality

- The compact design and low weight predestine the SWIR thermal imaging camera for integration into existing system environments

- The accompanying Software Development Kit (SDK) provides easy access to all camera functions

ImageIR® 8300 hp – The Flexible

High-speed Thermography Camera – Allrounder in VGA Format

- Large detector enables highest sensitivity

- (1,280 × 1,024) IR pixels by genuine camera hardware

- Analysis of extreme temperature changes and gradients in full frame

- Highly accurate and repeatable measurements

- High-speed, long-distance interference proof data transmission

- Flexible setting of temperature measurement ranges/integration times beyond calibration ranges

- Facilitates the analysis of objects with extreme temperature gradients

ImageIR® 8800 hp – The Long Wave

High resolution and speed – the cooled long-wave infrared camera

- Calibration of a multitude of calibration curves for precise temperature measurement

- Detection of smallest details with detector of (640 × 512) infrared pixels

- Snapshot detector with short integration times

- Modular concept for high flexibility

- Precise long-time measurements without shutter

ImageIR® 9400 hp – The 2 in 1 Camera

The high-performance infrared camera ImageIR® 9400 hp from InfraTec is suitable for solving extremely demanding tasks. It impresses with absolute top figures for geometrical, thermal and temporal resolution. This model can be used in high-speed mode, where 2×2 pixels are binned together to create a 640 x 512 fpa, and high resolution mode with a native fpa of 1280 x 1024 pixels. With microscan, this can be increased further to 2560 x 2048 pixels

- Cooled FPA photon detector with (1,280 × 1,024) IR pixels

- Opto-mechanical MicroScan with (2,560 × 2,048) IR pixels

- High-speed mode enabling frame rates up to 622 Hz in full frame

- Thermal resolution up to 0.02 K

- Extremely short integration times in the microsecond range

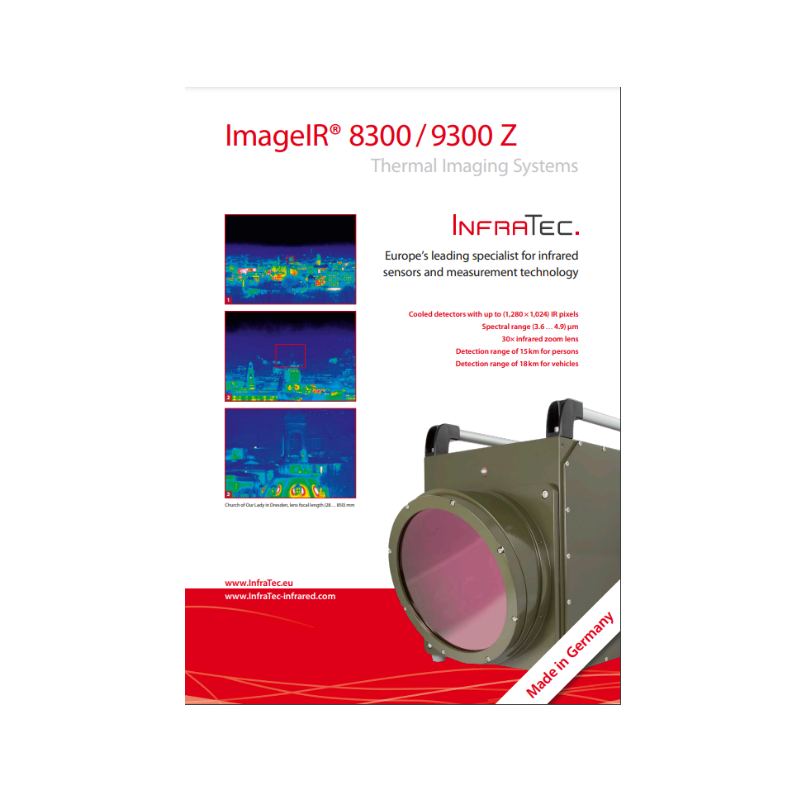

ImageIR® 9300 Z – The Zoom

The high-end infrared camera ImageIR® 9300 Z with 30× zoom lens allows effortless handling of complex reconnaissance and surveillance tasks.

- Cooled detectors with up to (1,280 × 1,024) IR pixels

- Detection range of 15 km for persons

- Detection range of 18 km for vehicles

- Customisable software interface offers time coded real-time playback

ImageIR® 10300 – The HD

With the ImageIR® 10300, users from industry and science for the first time can use a radiometric infrared camera whose cooled photon detector permits images in the format (1,920 × 1,536) IR pixels.

- Full HD resolution of about 3 Megapixels

- Pixel pitch of 10 µm

- Thermal resolution better than 0.03 K

- Measurement accuracy ± 1 °C or ± 1 %

- High-speed recording with previously unknown image quality

ImageIR® 6300 Z – The Efficient

Smaller, lightweight, without tedious lens changes – efficiency has a new name: The ImageIR®6300Z with a powerful zoom lens and a SWaP detector (Size, Weight and Power).

- Cooled focal plane array photon detector operating in snapshot mode with (640 × 512) IR pixels

- Standard built-in 7.5x zoom lens with motor focus

- Focal length of (15 … 115) mm or (25 … 170) mm

- Operation via smartphone or tablet with integrated web interface

- Compact size and low weight for space-saving system integration

- Storage of large amounts of data on the integrated SSD

Videos

Downloads

Supplier Info

Applications

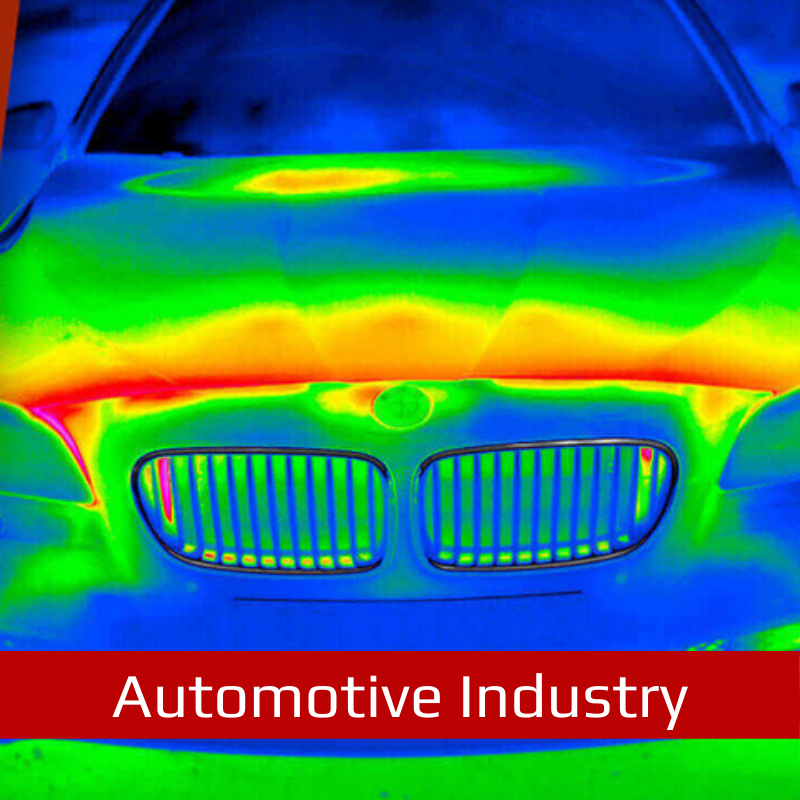

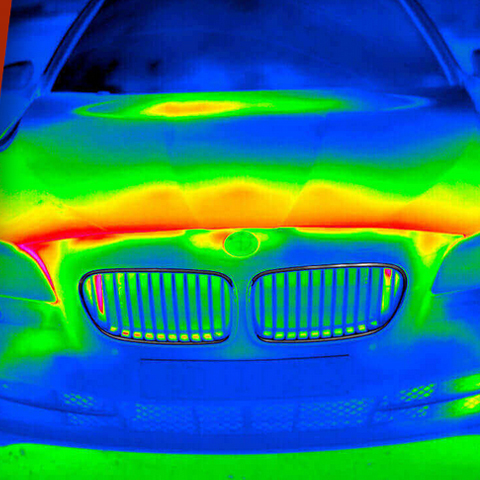

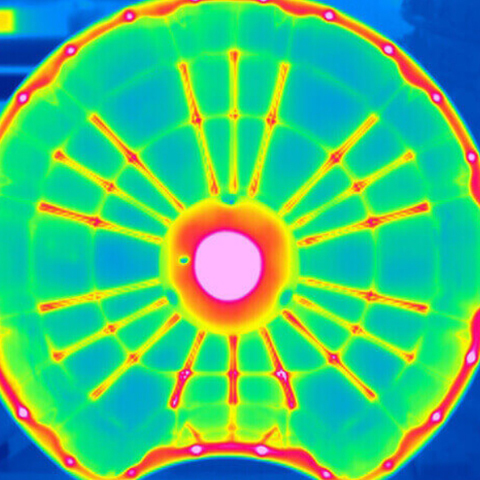

Thermography in Automotive Industry

Infrared camera systems help you to secure a high product quality in production and at your suppliers

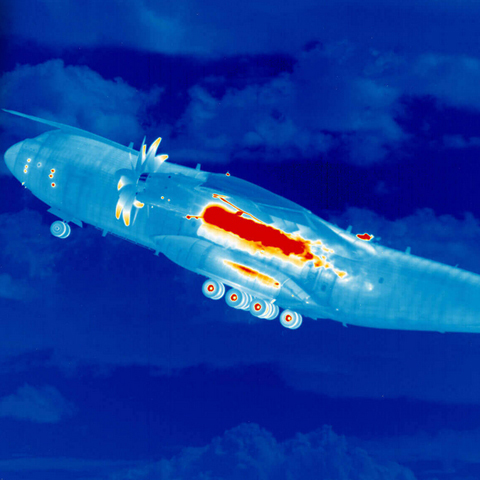

Thermography in Aerospace Industry

Comply with highest security demands by applying state-of-the-art infrared camera systems

Thermography in Medicine

Infrared camera systems help you to efficiently diagnose multiple illnesses with high certainty

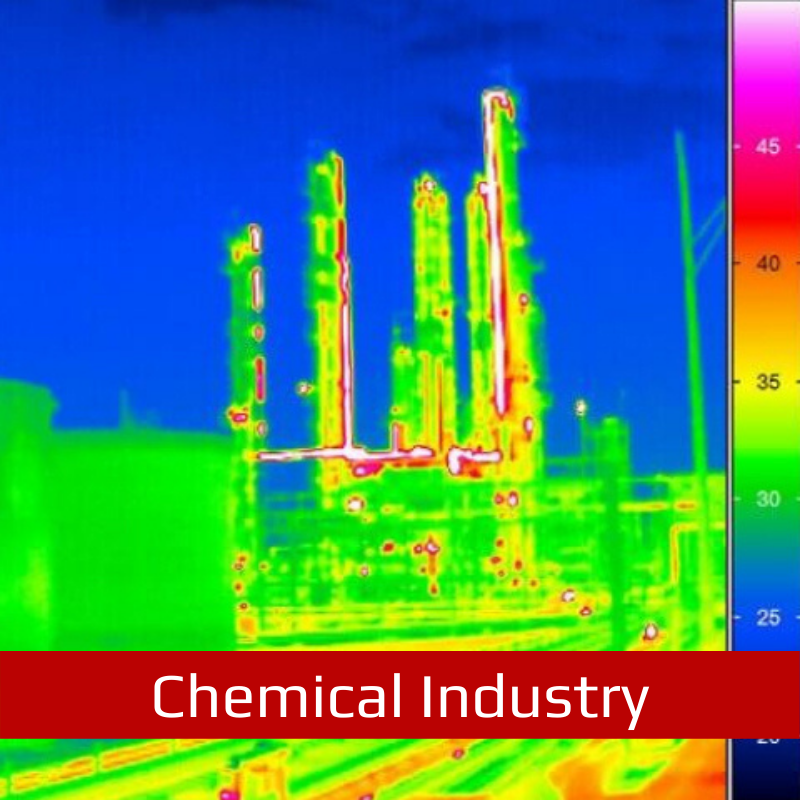

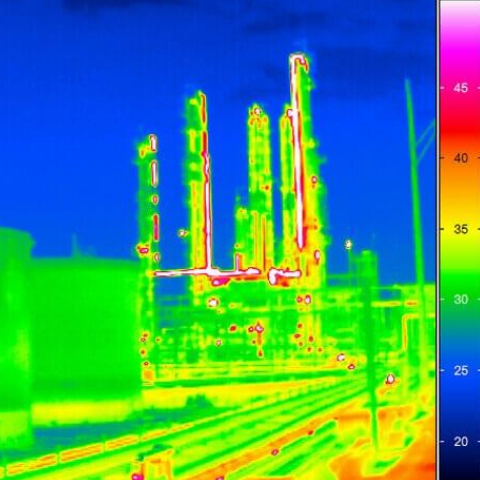

Thermography in Chemical Industry

Systematically control reactive process heat and display with infrared camera systems of InfraTec

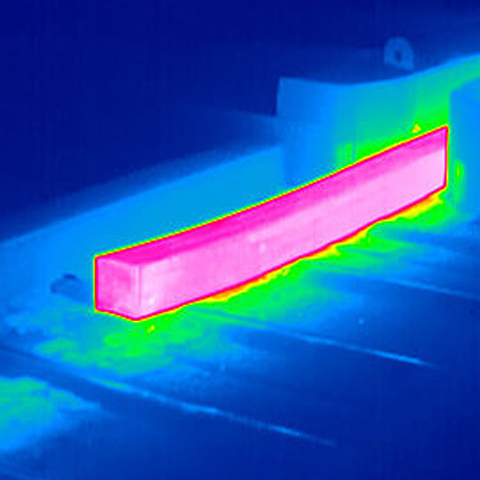

Thermography in Plastics Industry

Cost-efficiently control die-casting and extrusion processes by means of infrared camera systems

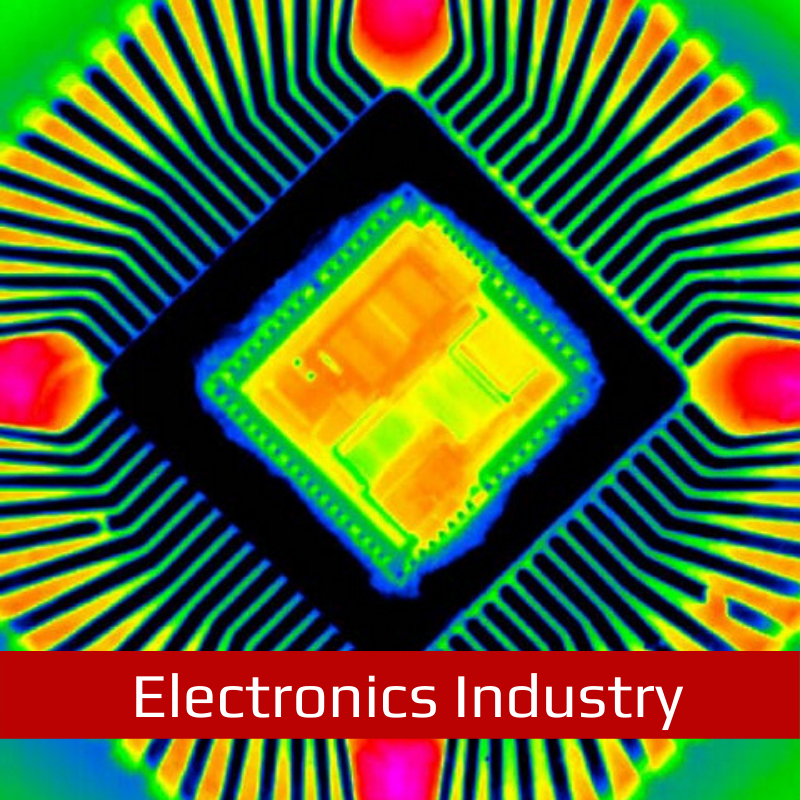

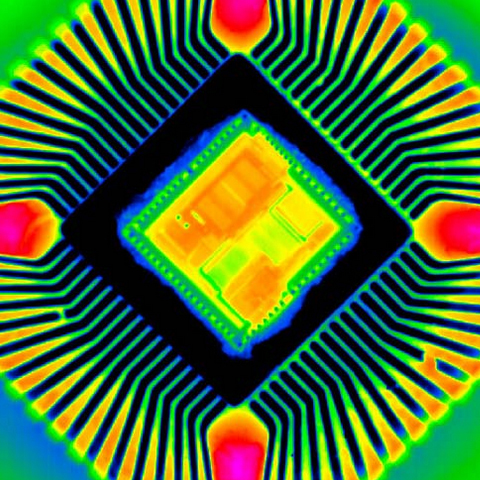

Thermography in Electronics and Electrical Industry

Measure temperature distributions of smallest electronic components with infrared cameras

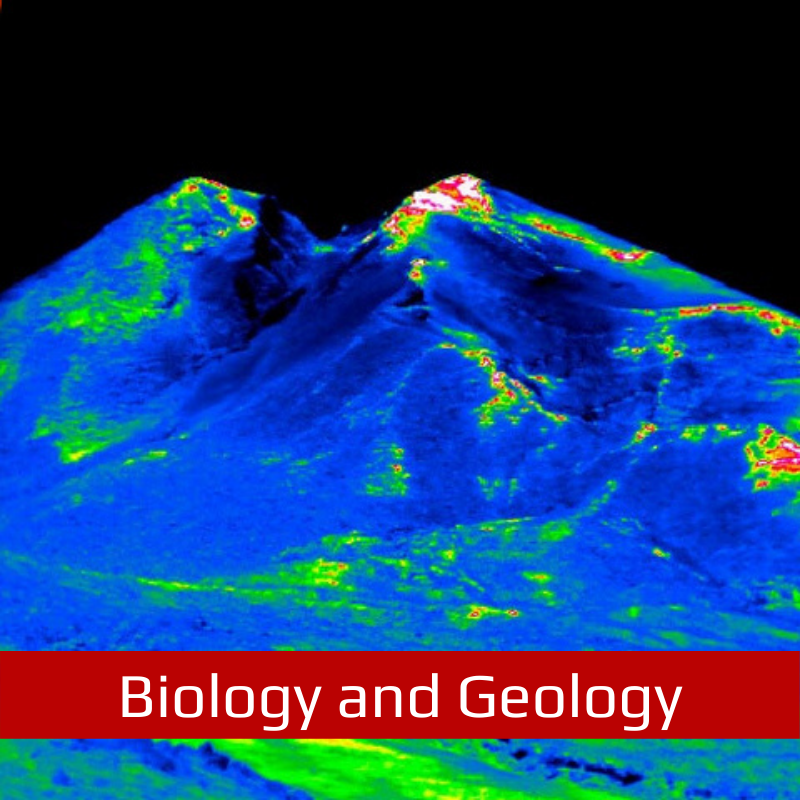

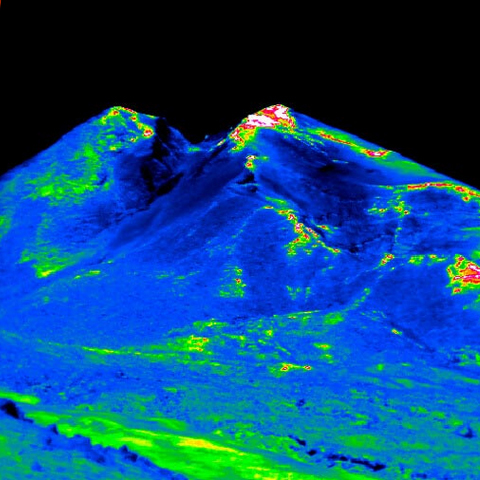

Thermographic Biologic and Geologic Studies

Look for smallest temperature differences in landscapes, biotopes and labs using infrared camera models of highest measurement precision

Thermography in Glass Industry

Measure correctly temperature distributions behind and on glass by using selected spectral filters