4D Technology’s NanoCam HD provides reliable, non-contact, 3D measurement of supersmooth optical surfaces.

Supersmooth optical surfaces are required in applications such as X-ray and Deep EUV mirrors, synchrotron optics, lenses for semiconductor equipment, laser gyro mirrors, and laser resonators.

For UV, EUV, and X-ray wavelength applications, optics must be extremely smooth to avoid scattering, which affects image quality, signal-to-noise, and other critical optical performance properties. The typically high incident energy can also degrade optics quickly. Thus, manufacturers and end users require a reliable, reproducible method to verify smoothness to sub-nanometer levels.

But, while newer manufacturing techniques have enabled production of supersmooth optics, the metrology to accurately measure these surfaces has lagged behind. To fill the void, the NanoCam HD optical profiler (Figure 1) has been proven to provide reliable, non-contact measurement of supersmooth surface texture, in situ on the shop floor.

The Challenge of Measuring Supersmooth Optics

“Supersmooth” surfaces typically have an RMS roughness (Sq) of less than 0.1 nm. Measuring such extremely smooth surfaces exceeds the capability of most measurement technologies. To date, stylus-based instruments and atomic force microscopes have been used. However, these techniques are very slow, and the contacting probes can damage the surfaces. Additionally, the measurement systems require highly controlled environments because vibration, shop noise, and air turbulence will degrade measurements.

Non-contact, optical profiling is the preferred method for quickly acquiring 3D data of supersmooth surfaces. Scanning white light optical profilers are most common. But the noise floor of scanning systems is typically too high to measure sub-angstrom roughness, even using phase-shifting interferometry (PSI) mode.

NanoCam HD Measures Supersmooth Surfaces

4D Technology’s NanoCam HD is an enabling technology for controlling the production of supersmooth surfaces. The NanoCam HD (Figure 2) offers several benefits that make sub-angstrom measurement possible.

NanoCam HD Benefits

- Non-contact, high resolution 3D measurement

- Measure despite vibration or turbulence

- Accurate and repeatable to RMS <0.1 nm

- Measure smaller optics quickly

- Measure larger optics anywhere in the shop

- Manual or automated positioning

Figure 2. NanoCam HD measuring a supersmooth reference optic.

Dynamic Interferometry

In recent years, vibration-immune “dynamic” interferometry has been adapted for roughness measurement. In dynamic instruments such as 4D Technology’s NanoCam HD, all measurement data is acquired simultaneously, rather than sequentially as in scanning methods. Such fast acquisition enables the NanoCam HD to measure in shop floor environments without expensive vibration isolation.

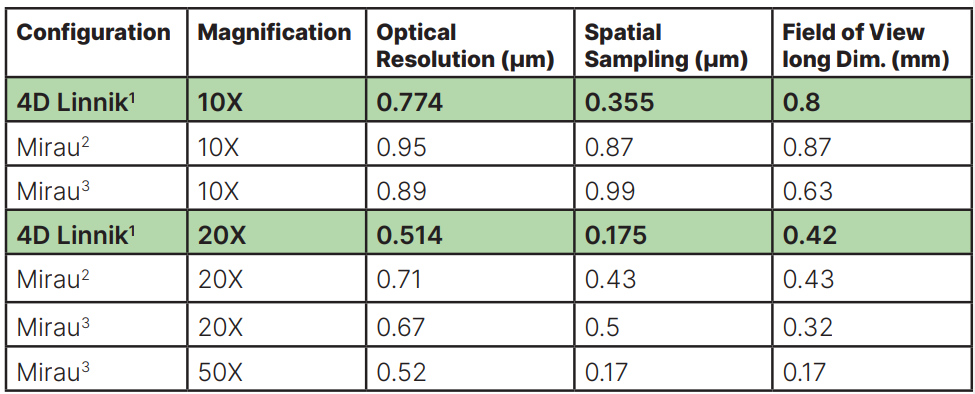

High-Resolution Objectives

4D Technology’s 10X and 20X Linnik format interferometric objectives provide

superior spatial resolution to the Mirau objectives used in many white light systems

(Table 1). In fact, the 20X 4D Linnik has comparable performance to a 50X Mirau.

The long working distance Linnik objectives are optimised to avoid thermal drift over

the duration of the measurement.

- With 4D Technology 5 MP camera

- Vendor 1 with 1 MP camera

- Vendor 2 with 0.3 MP camera

- Based on Sparrow criteria 0.5λ/Numerical Aperture

- Camera pixel size/magnification

Burst Measurement

Acquiring data quickly and thereby avoiding drift due to changing environmental conditions is one key to repeatable supersmooth measurements. The NanoCam HD’s Burst Measurement mode makes it possible to acquire multiple measurements in extremely rapid succession, followed by analysis as a separate, postprocessing stage. Burst mode ensures the most consistent and reliable data. A typical burst measurement consisting of 10 averages of 16 frames each can be acquired in ~10 seconds*

Signal-to-Noise Optimisation

The best vertical resolution is obtained by maximising the signal-to-noise ratio (SNR), which

means using all of the measurement instrument’s dynamic range. With an interferometer this can only be accomplished by matching the intensity of the test and reference beams.

The NanoCam HD is the only system which allows the user to adjust the ratio of the beams to achieve the highest SNR and thus the lowest noise measurements.

*Additional processing time is required to analyse the data once all acquisition is complete

Autofocus

Automatic focusing adapts to small changes in the environment, including thermal drift. Autofocus improves repeatability for manual dynamic measurements, and it makes robot-based measurements possible.

Reference Subtraction

A reference measurement captures the small error in the test system’s optics (Figure 3)so that it can be removed from each measurement. Subtracting the reference measurement with the NanoCam’s 4Sight Focus software is extremely easy and ensures the highest quality measurements.

Measuring Large Optics

Most metrology systems are limited to measuring optics that can physically fit beneath the measurement probe. For large optics, which cannot fit under the measurement probe, the traditional approach has been to measure a smaller witness sample instead. However, for supersmooth surfaces, the difference between the actual surface and witness surface can be significant, and measuring a witness sample is insufficient to assess the actual surface.

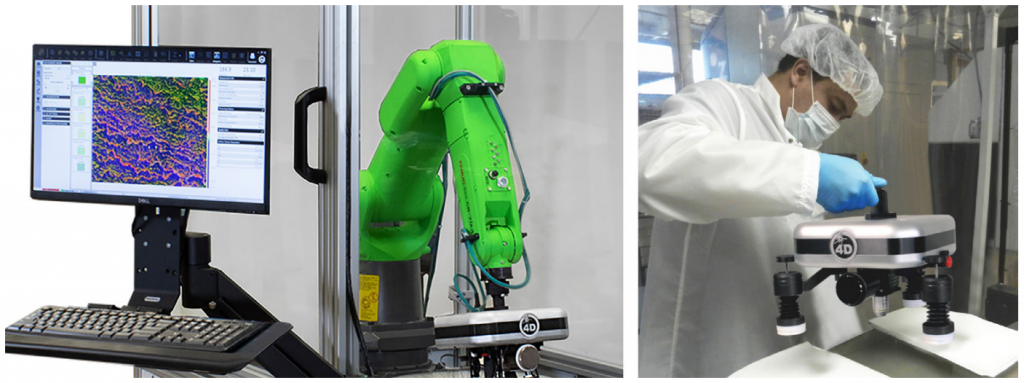

Because the NanoCam HD is vibration-insensitive, it can be mounted on a robot and positioned automatically to measure large optics (Figure 4). Robotic positioning enables rapid measurement at many locations around the optic. The instrument can also be placed manually on the surface, using its protective tripod feet and lint-free cloths.

with the manual tripod option

Supersmooth Roughness Qualification

To demonstrate the capabilities of the NanoCam HD, a supersmooth, NIST certified reference mirror with roughness < 0.1 nm RMS (Figure 2) was tested in standard office conditions, without a floating optical table or air movement abatement. The results that follow are obtainable in both manual and robotic mounting configurations.

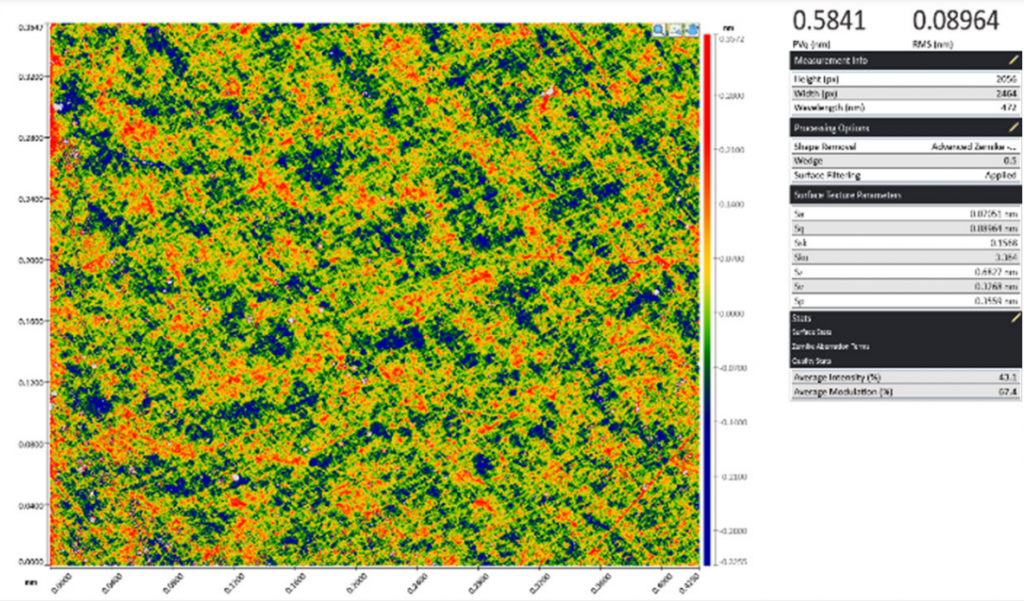

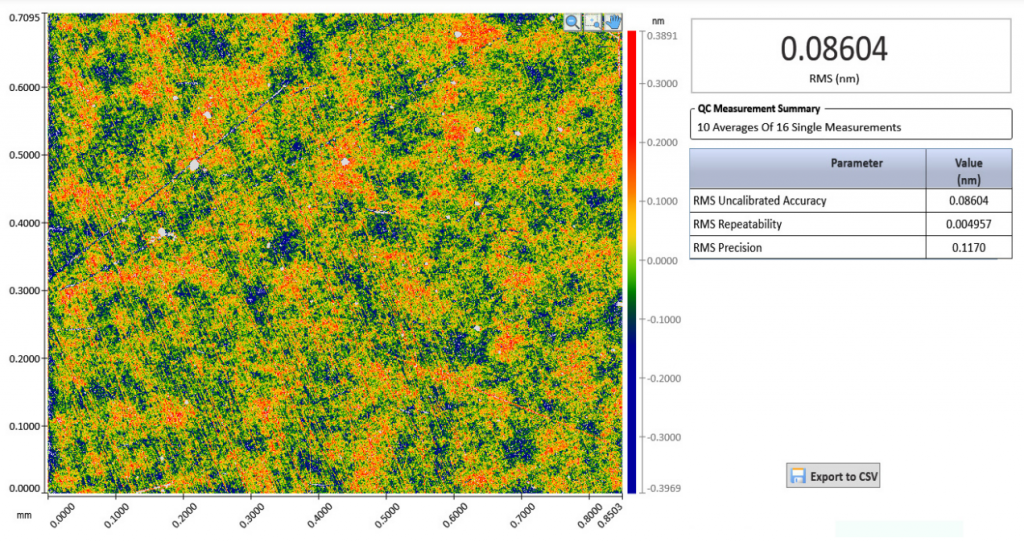

Repeatability

To demonstrate repeatability, ten measurements consisting of 16 averages each were acquired. The repeatability from a single measurement is shown in Figure 5. The NanoCam measured the surface roughness as 0.086 nm RMS. The 0.005 nm repeatability, less than an order of magnitude smaller than the measured values, indicates the high quality of the measurement results.

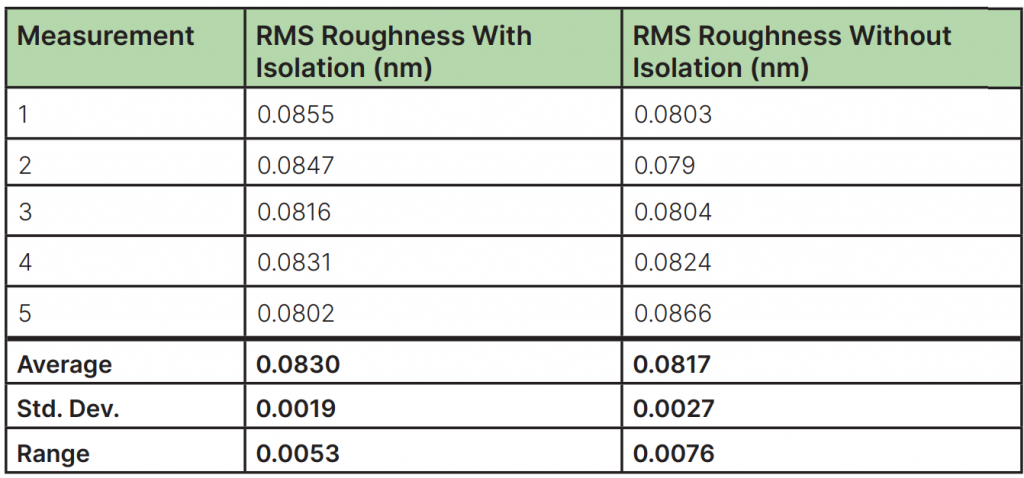

To understand the impact of vibration on the measurements, an additional set of tests were performed with and without vibration isolation. For both conditions, five measurements were acquired, each consisting of 10×16 averaged measurements. The results are summarised in Table 2. The similarity of the RMS numbers with and without isolation indicates that the NanoCam HD will provide repeatable data, even in the presence of typical levels of environmental noise.

Measurement Validation

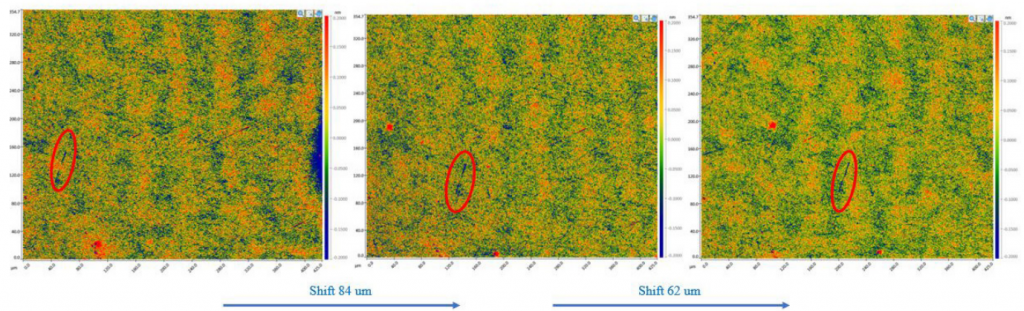

Interferometric results are a combination of the reference and test surface. Figure 6 shows three measurements that were made of the supersmooth reference, with the reference translated laterally by ~20% of the field of view between frames. In these measurements, identifiable features clearly shift with the data, indicating that they are part of the actual surface and not part the optical system.

The NanoCam HD dynamic interferometer fills an important need for measuring

sub-Angstrom roughness in production environments. Vibration-immune and highly

portable, the NanoCam HD demonstrates excellent repeatability and correlation for

these challenging measurements, on small and large optics without leaving the shop

floor.

For any questions on the application note or interferometry in general, please contact our Technical Sales Manager, Dr. Luke Nicholls by email or call (01372) 378822. You can also find more information about the 4D NanoCam here, or at www.4dtechnology.com

NanoCam and 4Sight Focus are trademarks of 4D Technology Corporation. ©2023 4D Technology Corp.