- Features

- Options

- Videos

- Downloads

- Applications

- Related Products

- Contact

- Back To Spectroscopy

- Back To Optics

- Back To Hyperspectral

- Back To Cameras

- Back To X-Ray

- Back To Light Measurement

- Back To Characterisation

- Back To Electron Microscopy

- Back To Magnetometry

- Back To Ellipsometers

- Back To Cryogenics

- Back To Lake Shore

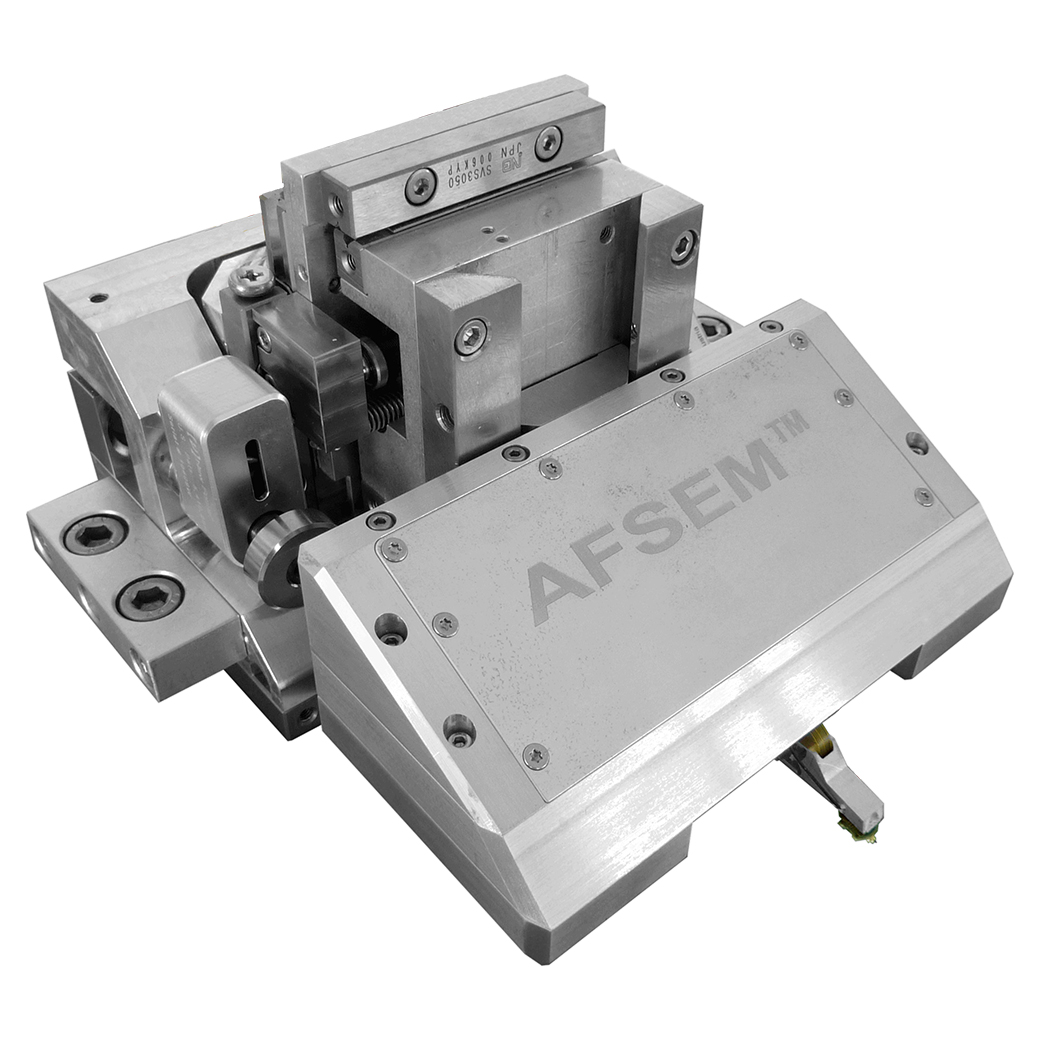

NanoMEGAS A-Star TEM Orientation Imaging

Nanoscale TEM Orientation Imaging Analysis

ASTAR can turn any TEM into a very powerful analytical tool enabling orientation – phase imaging at 1 nm resolution attainable (FEG TEM) in combination with other TEM analytical techniques. In combination with TOPSPIN simultaneous orientation/phase/strain /STEM maps are possible.

All these techniques are based on Precession Electron Diffraction acquired data in TEM and are high‐end techniques that can be applied for various materials of high scientific and/or industrial interest. These state‐of‐the‐art approaches can be applied in any TEM, providing results within spatial resolutions up to 1‐3nm (ASTAR, TopSPIN) when an FEG nanobeam is used. Such resolution makes these applications unique, and able to shed light on local properties of materials like thin films, metals, batteries, ceramics, semiconductors.

FEATURES

- Compatible with any TEM 120-200-300 Kv (LaB6 /W- FEG)

- ASTAR orientation-phase map 1 nm resolution with TEM-FEG

- ASTAR works with any type of diffracting material (inorganic/organic) using standard TEM specimen preparation techniques

- ASTAR can work/ retrofit between multiple TEMs in same lab

- Galvanic Isolation system (GIS) via optical fibre for ASTAR -TEM connection

OPTIONS

Videos

Downloads

Supplier Info

Applications

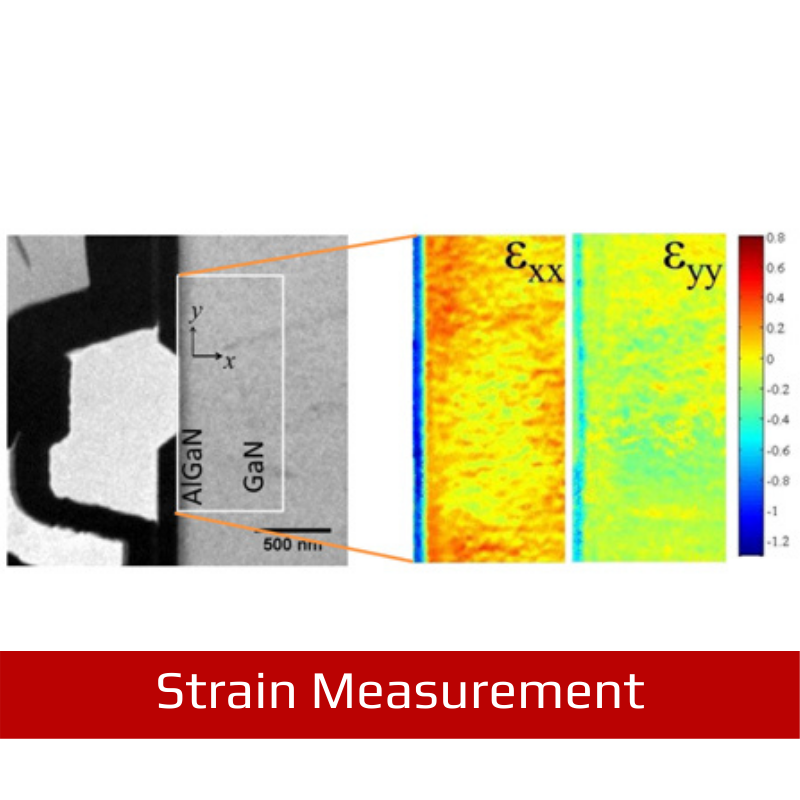

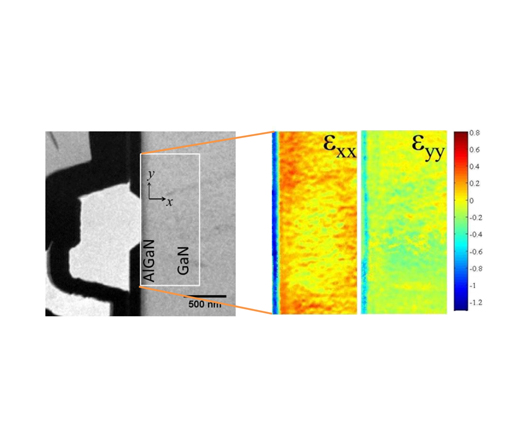

Strain Measurement

Measurement of strain with high spatial resolution and high precision in semiconductor devices is critical to monitor the designed and unintended strain distributions. Use of spot diffraction patterns with nanobeam illumination gives higher spatial resolution than other TEM techniques.

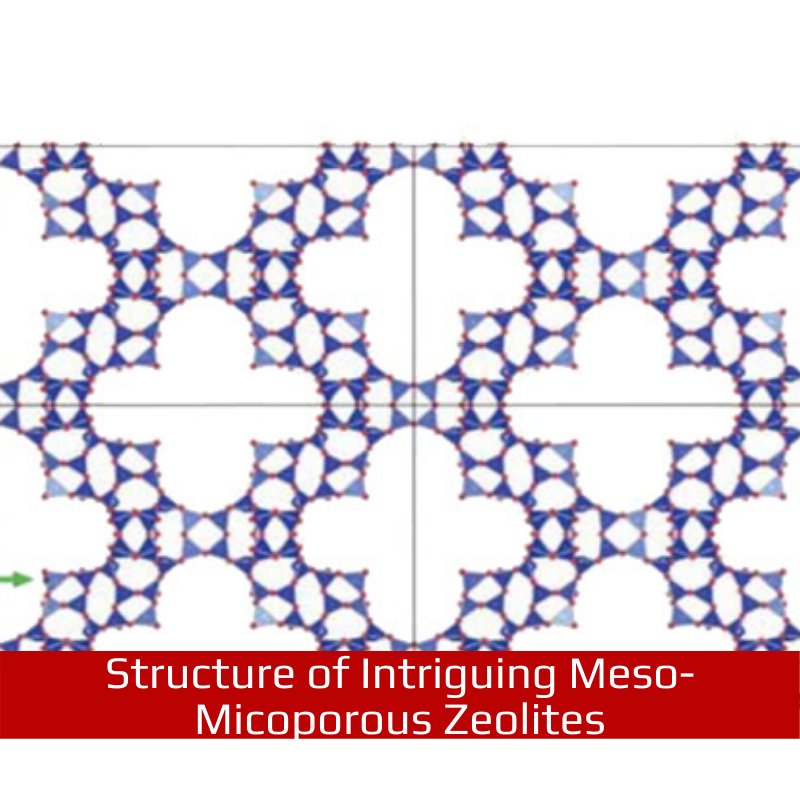

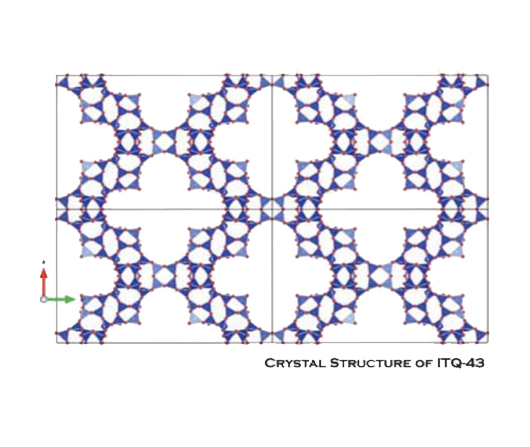

Structure of Intriguing Meso-Microporous Zeolites

Zeolites are crystals that are mainly created from aluminium and silicate. They have small pores which make them interesting for the field of energy and environmental technology due to their potential use as adsorbers, ion exchangers or catalysts.

Architecture of Hybrid Nanocrystalline Microporous Materials

The synthesis of aluminosilicate hybrids with organic groups fused within a crystalline framework is a daunting mission which has eluded many workers. Hybrids add variable chemical modification to the repertoire of zeolites, which are well established as heterogeneous catalysts, ion exchangers, and molecular sieves with many different pore architectures.

From Clean Energy Cars to Structure of Metal-Organic Framework Materials (MOFs)

Fossil fuels are not renewable, which means that if the world uses them uncontrollably, fuel will be limited in the future. Hydrogen is an attractive energy carrier which could replace petroleum. However, hydrogen storage is a difficult problem which still has to be solved.

Inside the Structure of Dye-Sensitised Solar Cells

Dye-sensitised solar cells (DSSCs) belong to the family of thin film solar cells and are an attractive and considerably cheaper way of producing electricity. DSSCs are designed like a traditional alkaline battery and do not require tricky manufacturing process.

Towards Alternative Energy Sources: Structure of Thermoelectric Nanomaterials

Solar cells operating at 20% efficiency and covering 0.1% of the Earth's land area would be sufficient to supply the worldwide yearly energy requirement. The Sun as an energy source can also be used by thermoelectric (TE) modules which directly convert solar heat into energy.

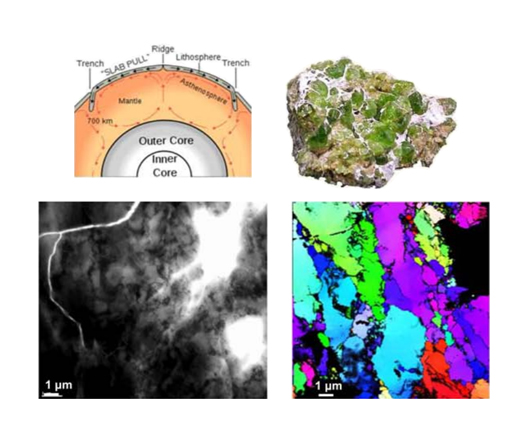

Shed Light to Magma Genesis & Seismicity

The processes that give rise to arc magma at convergent plate margins have long been a subject of scientific research and debate. H2O-transfer from the subducted slab to the overlying mantle wedge has been largely recognised as one of the major processes driving rheological modifications of the upper mantle, affecting its petrological variablilty and promoting magma genesis.

Charoite: The Enigmatic Structure of "Unnaturally Beautiful" Gemstone

Charoite is a rare mineral first described in 1978 and named after the chara River. Charoite is translucent lavender to purple in colour with a pearly lustre. Charoite is strictly massive in nature, and fractures are conchoidal. It has an unusual swirling, fibrous appearance, sometimes chatoyant, and that along with its intense colour, can lead many to believe at first that it is synthetic or enhanced artificially.

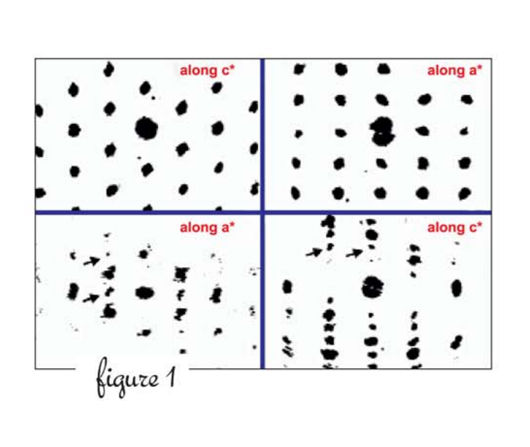

Structure of New Sarrabusite Mineral

The new mineral Sarrabusite Pb5CuCl4(SeO3)4 has been discovered in Baccu Locci in southeastern Sardinia, Italy. This mineral was discovered in the late 90's and was tentatively assigned as Pb5CuCl4(SeO3)4OH) based on EDX. However, owing to the exceeding small dimensions, no structural study could be preformed using conventional X-ray diffraction and the nature of this possibly new species remained unknown for more than a decade.

Structure of Embedded Nanodomains in Intermetallics

Ni-Te is an intermetallic compound with possible applications in thermoelectric generators (TEGs) that convert heat into electrical power by exploiting a temperature gradient. The system is a two-solid phase mixture where nanodomains of modulated (layered) unknown phase were found inside the NiTe matrix.

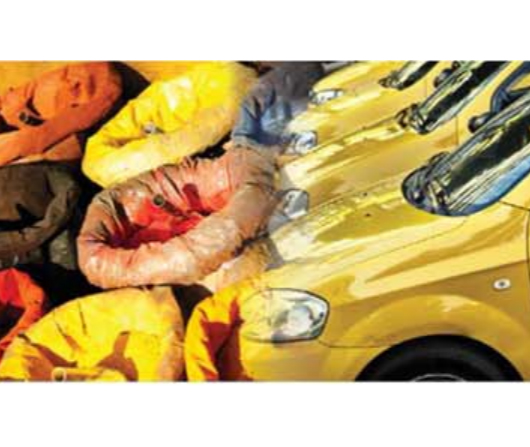

Structure of Pigment Yellow for the Car Industry

Some years ago, the automotive industry turned their interest from solvent-based to water-based coatings. This led to the requirement of novel water-dispersible pigments. Greenish-yellow shades appeared to be one of the most problematic, because all existing greenish-yellow pigments were either not dispersible in water or had an insuffienct weather fastness, i.e. they faded out after a few years.

Structure of Organic (CNBA) Molecules

The photo-optical properties of 9,9'-bianthracene-10-carbonitrile (CNBA) in solution are related to the angle between the two anthracene moieties. The 9,9'-bianthryl and its analogues are well-known systems whole excited state behavious and dynamical processes have been studied extensively in a range of conventional solvents.

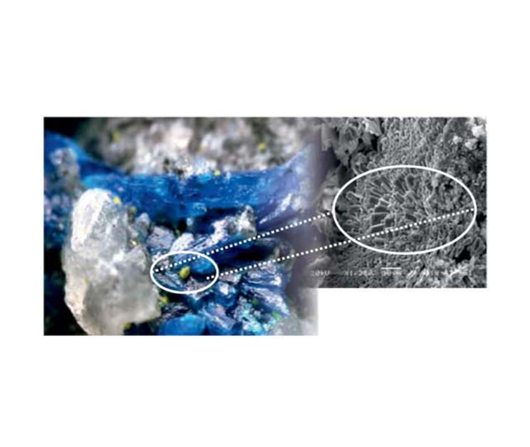

Bio-Mineralisation Process in Sea Environment

Among the siliceous sponges, the spiculogenesis in the demosponge is best understood. It was suspected that the intial stages of spicule formation proceed intracellularly. Because the synthesis of the spicules is a rapid process, the earliest stages of spicule formation can be studied under in vitro conditions in the cell culture system, the primmorphs.

What is Stacking in Our Pipes: The Structure of Vaterite

Vaterite, one of the common natural CaCO3 polymorphs, plays a pivotal role in weathering and biomineralisation processes. Vaterite is important for the problems of scales in pipes, biomineralisation of mollusks and pearls. Differently from calcite and aragonite, vaterite can be found only in the form of nanosized crystals, not suitable for structure determination by X-ray diffraction.

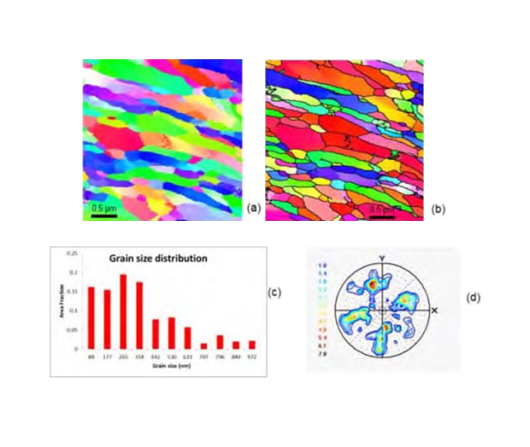

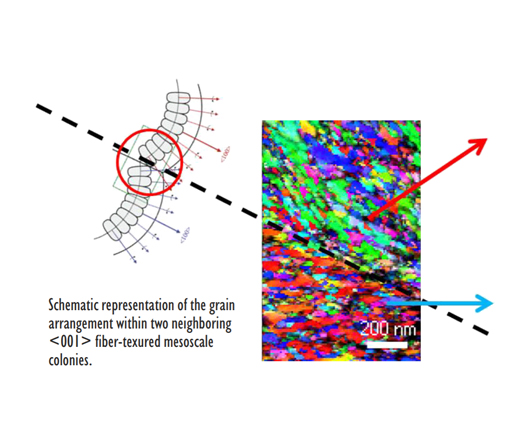

Design Materials with Specific Applications

Titanium alloys are metals which contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and durability (even at extreme temperatures). They are light weight, have extraordinary corrosion resistance and the ability to withstand extreme temperatures. However, the high cost of both raw materials and processing have limited so far their use in certain applications.

Better Steels with Improved Properties

Steel is an alloy made by combining principally iron and carbon; moreover other alloying elements are used to improve mechanical characteristics , such as manganese, or vanadium. The resulting steels are commonly known as High Strength Low Alloy Steels (HSLA). Carbon and other elements act as a hardening agent, preventing dislocations in the iron atom crystal lattice from sliding past one another.

Challenging Materials for Challenging Applications

Synthetic Sapphire is a single crystal form of corundum, Al2O3, also known as alpha-alumina, alumina, and single crystal Al2O3. Synthetic sapphire is the hardest of all known oxide crystals with a 9 on the Mohs scale. It is second in hardness only to diamond, and retains its strength at high temperatures. Synthetic sapphire crystals have good thermal properties, with excellent electrical and dielectric properties.

Steel Corrosion in Nuclear Plants

Generation IV reactors (Gen IV) are a set of theoretical nuclear reactor designs currently being researched. Most of these designs are generally not expected to be available for commercial construction before 2030. Current reactors in operation around the world are generally considered second- or third-generation systems, with most of the first-generation systems having been retired some time ago.

Metal Under Huge Stress

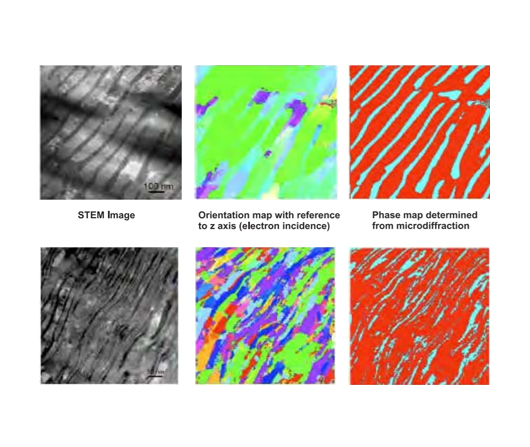

Silver and copper have a wide miscibility gap therefore special methodologies are needed to obtain a metastable alloy. The usual results of a Cu-Ag alloy synthesis is spinodal decomposition of Ag, Cu phases intergrown in bands some hundred nanometers wide. A way to push the spinodal decomposition to a smaller scale is given by the severe plastic deformation induced by a high pressure torsion (HPT).

Pavements of the Nanoworld

One effective method of producing nanocrystalline materials (grain size < 100 nm) is pulsed electrodeposition. It has been observed that electrodeposits form and grow in a nodular fashion each nodule representing a “colony” of nanosized grains. TEM has been used to investigate the local microtexture and Pole figures revealing ocal orientation measured at the interface between two colonies.

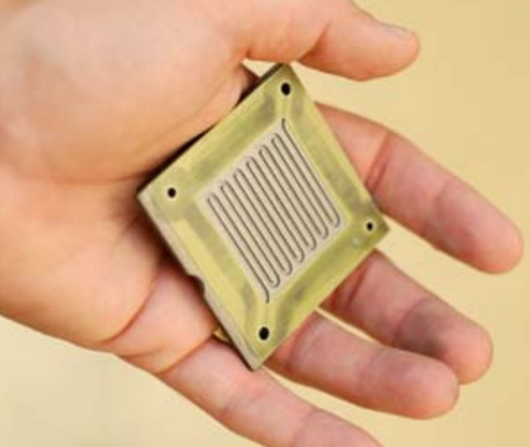

Nanoscale Reaction Models in Solid Oxide Fuel Cells

Solid oxide fuel cell (SOFC) technology is a promising energy conversion option at a time when efficient solutions are sought. During the electrochemical reaction of a fuel with an oxidant gas (usually air) at an operation temperature of ~ 800°C, SOFCs cogenerate heat and electricity with high efficiency: Electric efficiencies close to 60% are obtained now with a SOFC alone.

Next Generation Circuits for Semiconductor Industry

The scaling down to reach faster chip performances in electronic devices has pushed the dimensions of copper interconnect (CI) lines to the nanometre domain. This constant downscaling of CIs implies a change in their microstructure. A change in the grain boundary type distribution and local teture will strongly influence the resistivity and the mechanical reliability of downscaled CIS.

Structure of Magnetic Semiconductors

Magnetic Semiconductor materials have attracted widespread attention in recent years due to their potential application for the transport of information by exploiting both the intrinsic spin of the electron and its associated magnetic moment, in addition to its fundamental electronic charge.The new technology which emerged from discoveries in solid-state devices was called spintronics ("Spin Transport Electronics") also known as magnetoelectronics.

Hybrid Inorganic/Organic Systems for Optoelectronics In Daily Life

Nanocrystalline ZnO is provided in an inorganic/organic system of ZnO deposited on sexiphenyl (6P). Initially 6P was deposited on a-plane ZnO substrate at room temperature forming mesoscopic 1-dimensional islands of 6P. In a second step, the islands were capped with ZnO via molecular beam epitaxy at 373 K. Information on the nanostructure of ZnO grown atop 6P was provided by high-resolution TEM.

Atomic Scale of Nanolayer Composites

A stacking fault is a one or two layer interruption in the stacking sequence of the crystal structure. These interruptions carry a certain stacking fault energy (SFE). High SFE materials such as Al do not form twins easily. However, researchers have shown that it is possible to form Al layers in twin orientation to each other across polar TiN layers, if these are grown so that both the Al and TiN layers have a {111} surface as their growth front.

Understanding Li Insertion Mechanism for Next Generation Batteries

Lithium iron phosphate (LiFePO4) is a good candidate for positive electrodes in lithium-ion batteries to be installed in new electric vehicles. Its cost is low, it has an excellent life cycle and it is safe. To obtain the best performance in terms of electrical conductivity it is synthesised in nanocomposite with grain size between 50 and 300 nm.

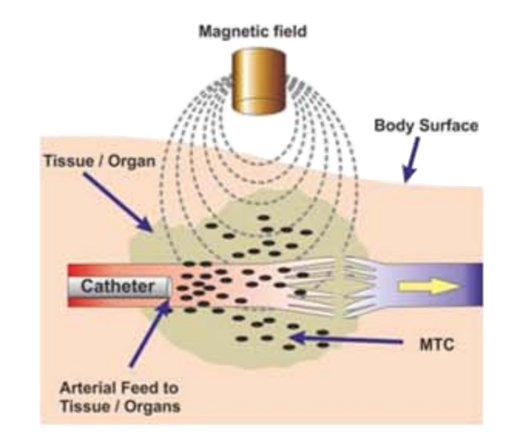

Drug Delivery & Structure of Nanoparticles

Iron oxide nanoparticles (usually below 20 nm) are being investigated for biomedical applications because of their biocompatibility and unique physical properties. This biocompatibilty result from their capacity for metabolism, transportation and storage of human tissues. Magnetic iron oxide particles with diameter above 20 nm are ferromagnetic, which generates unstable particulate suspensions, as the particles aggregate together into biologically toxic, micron-sized clusters.

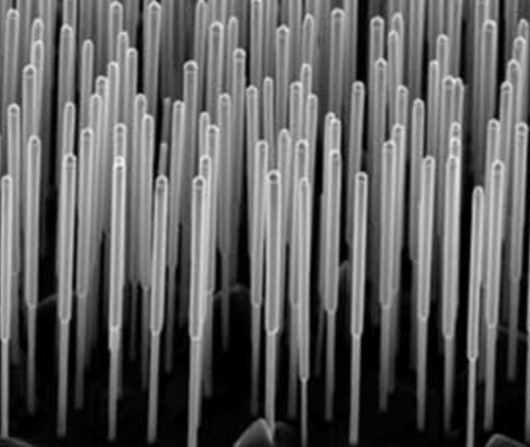

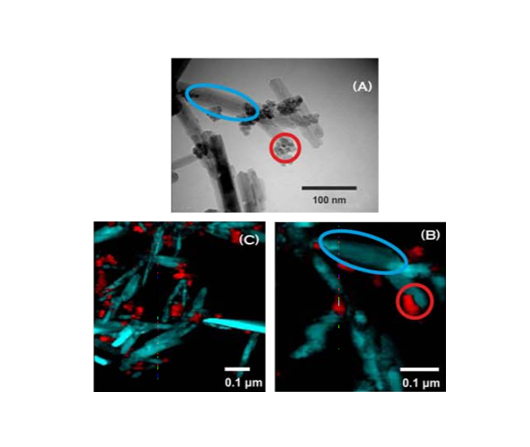

Inside the Nanowire Forest

III-V semiconductor nanowires are at the forefront of solid state physics and technology. Nanowires are quasi one dimensional crystals that can be heterostructured in different sectors having different chemical composition and crystal structure. They are grown by chemical beam epitaxy (CBE) from a III-V wafer with the Au-assisted growth method. In this method the wafer is coated with a thin layer film that by a dewetting thermal treatment in the CBE chamber transforms into small Au nanoparticles.

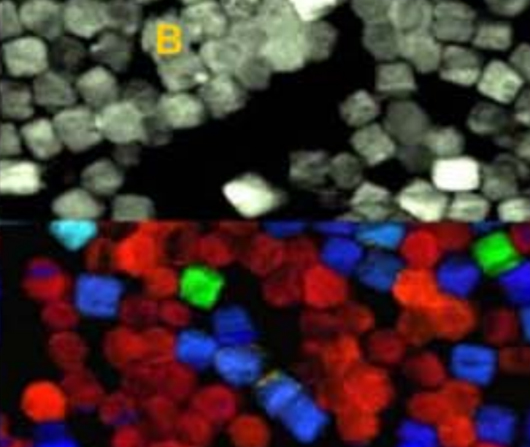

Texture Secrets of Nanoparticles

Nanoparticles are now a hot topic in several different fields for their astonishing and unusual properties compared to bulk materials. New sciences like nanochemistry, nanomedicine and nanotoxicology are born and an accurate knowledge of the nanoparticle structure is required to model properly their useful properties. Among these, the grain size, the defects and the particle shape are of major importance, since they easily correlate especially with optical properties.

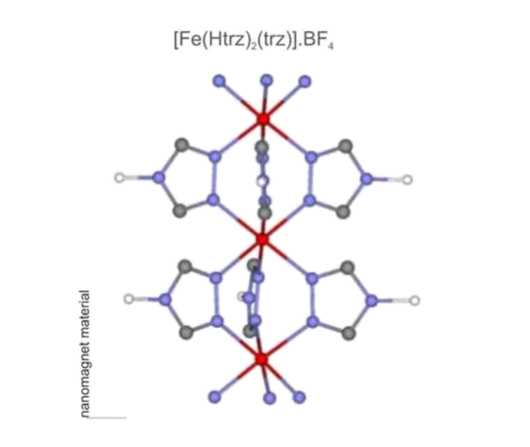

Crystal Orientation Imaging of Organic Nanomagnets

The development and characterisation of nanometre-scaled functional molecular-based materials have recently attracted much attention. Molecular nano-objects offer the possibilty of tuning or combining magnetic, optical or electrical properties by a rational synthetic chemical approch. These materials present promising technological applications in molecular electronics, or magneto-optic memory devices providing that we can design single domain particles with hysteresis behavious in the future.

Inside a Roman Ceramic Factory in Ancient Gaul

Terra sigillata is certainly the most famous fine ware of the Roman period with characteristic decorations obtained by means of specially designed stamps (sigilla). This pottery was extensively produced in standardised shapes by a few specialised workshops and was widely distributed across the Roman Empire. The success of this pottery was mainly because of the brightness and red colour of the slip.

Shed Light to Earth Seismicity

The mineral olivine dominates the composition of the Earth's upper mantle and hence controls its mechanical behaviour and seismic anisotropy. Experiments at high temperature and moderate pressure, and extensive data on naturally deformed mantle rocks, have led to the conclusion that olivine at upper-mantle conditions deforms essentially by dislocation creep with dominant [100] slip.

The World of Mineral Polymorphs & Textures

Inorganic nanoparticles are widely used in catalysis. Research has led to control their morphology, crystallographic orientation and assembly. Metal oxide composites can be formed by heteroaggregation using electrostatic forces induced by the surface charges of the nanoparticles. It is important to understand the mechanisms of heteroaggregation and in particular the role of crystallographic facets.