- Features

- Options

- Specifications

- Downloads

- Related Products

- Back To Spectroscopy

- Back To Optics

- Back To Hyperspectral

- Back To Cameras

- Back To X-Ray

- Back To Light Measurement

- Back To Characterisation

- Back To Electron Microscopy

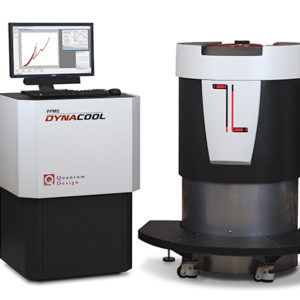

- Back To Magnetometry

- Back To Ellipsometers

- Back To Cryogenics

- Back To Lake Shore

Moxtek NanoStructure Solutions™

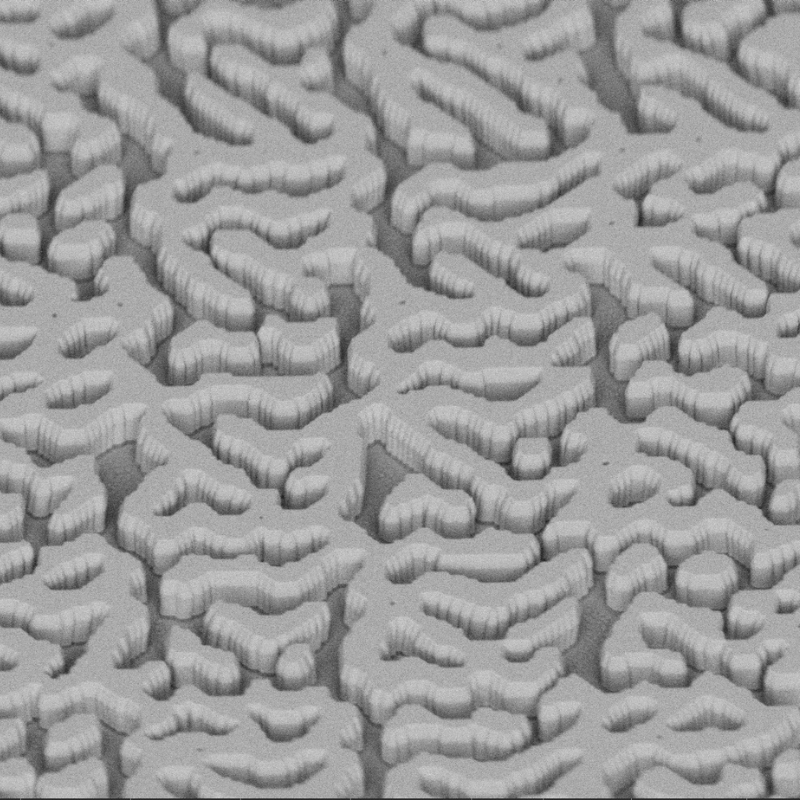

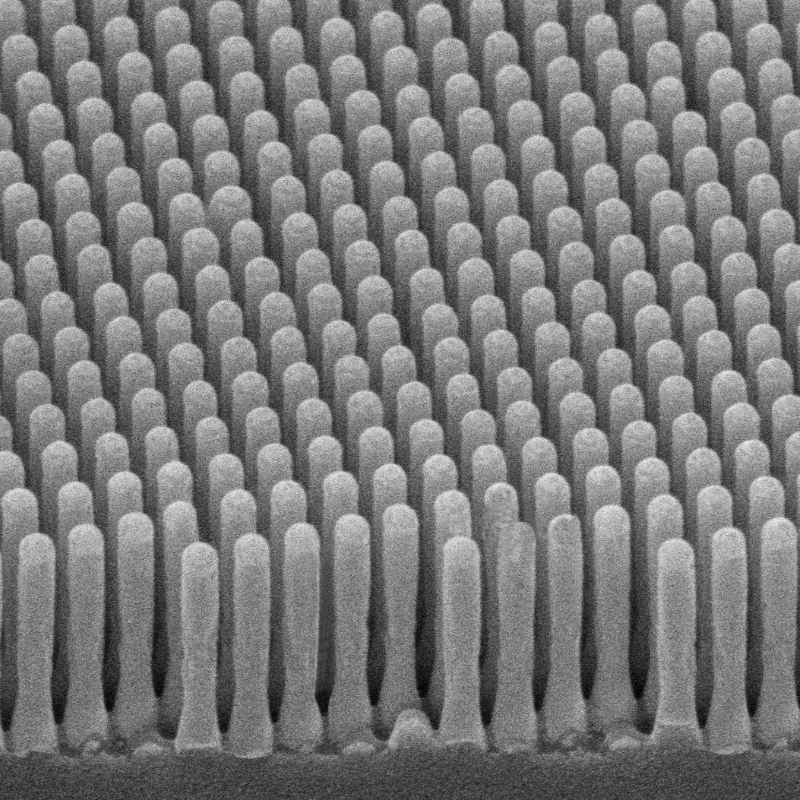

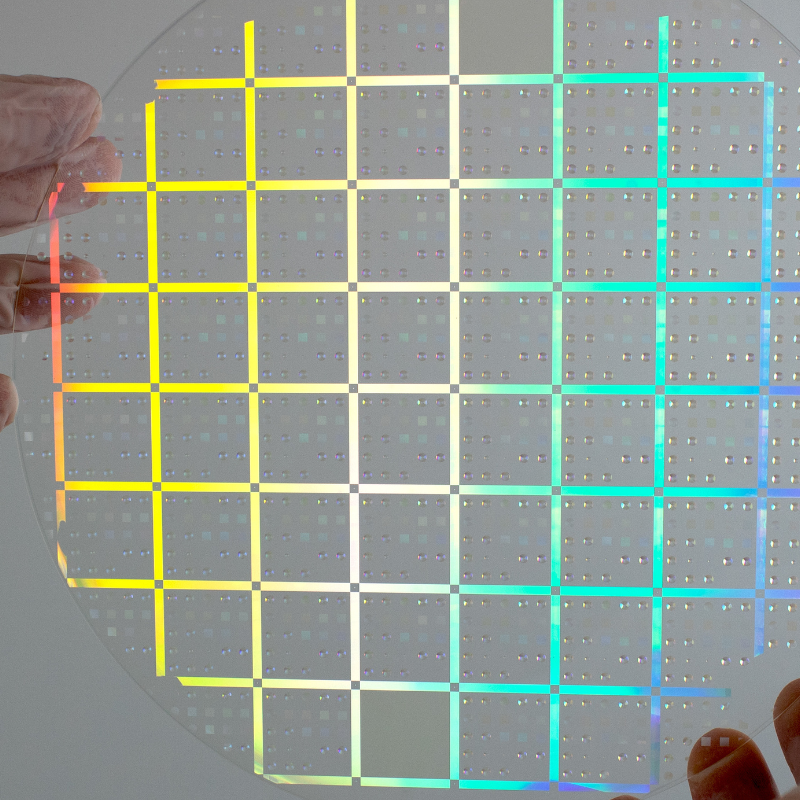

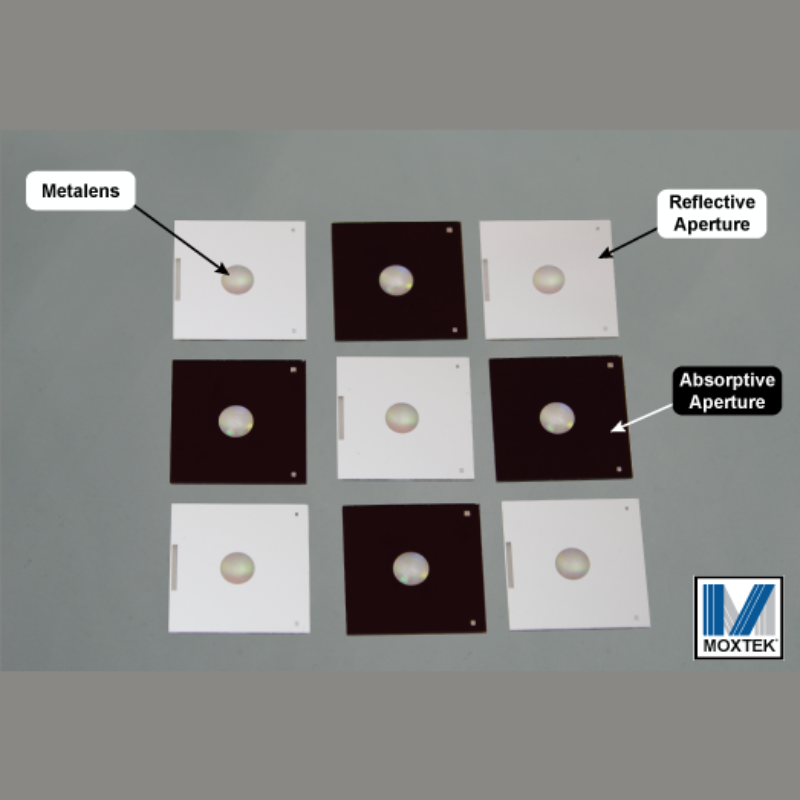

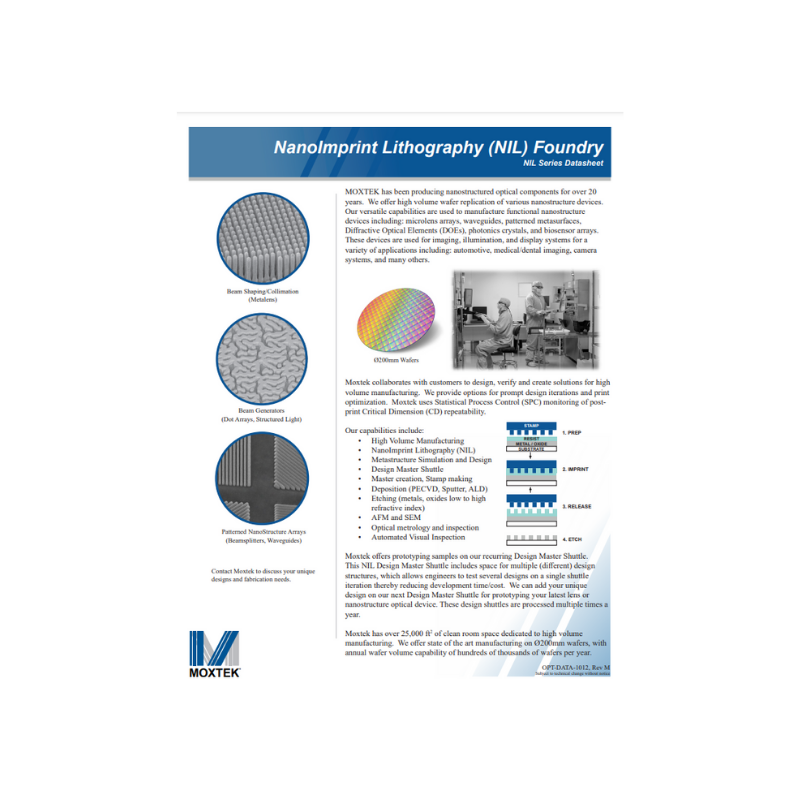

MOXTEK has been producing nanostructured optical components for over 20 years. They offer high volume wafer replication of nanostructure devices on Ø200mm wafers. Moxtek’s versatile capabilities are used to manufacture functional metasurfaces including: metalens, meta-optical elements (MOE), diffractive optical elements (DOE), patterned nanostructures, waveguides, photonics crystals, and biosensor arrays. These devices are used for imaging, illumination, and display systems for a variety of applications including: automotive, medical/dental imaging, camera systems, and many others.

Moxtek collaborates with customers to design, verify and create solutions for high volume manufacturing. We provide options for prompt design iterations and NanoImprint Lithography (NIL) optimisation. Moxtek uses Statistical Process Control (SPC) monitoring of post-print Critical Dimension (CD) repeatability.

Moxtek offers prototyping samples on their recurring Design Master Shuttle. This NIL Design Master Shuttle includes space for multiple (different) design structures, which allows engineers to test several designs on a single shuttle iteration thereby reducing development time/cost. Moxtek can add your unique design on our next Design Master Shuttle for prototyping your latest lens or nanostructure optical device. These design shuttles are processed multiple times a year.

MANUFACTURING CAPABILITIES

- High Volume Manufacturing

- Prototyping Options

- NanoImprint Lithography (NIL)

- Design Master Shuttle

- Master creation, Stamp making

- Deposition (PECVD, Sputter, ALD)

- Etching (metals, oxides low to high refractive index)

- AFM and SEM

- Optical metrology and inspection

CONFIGURABLE PARAMETERS

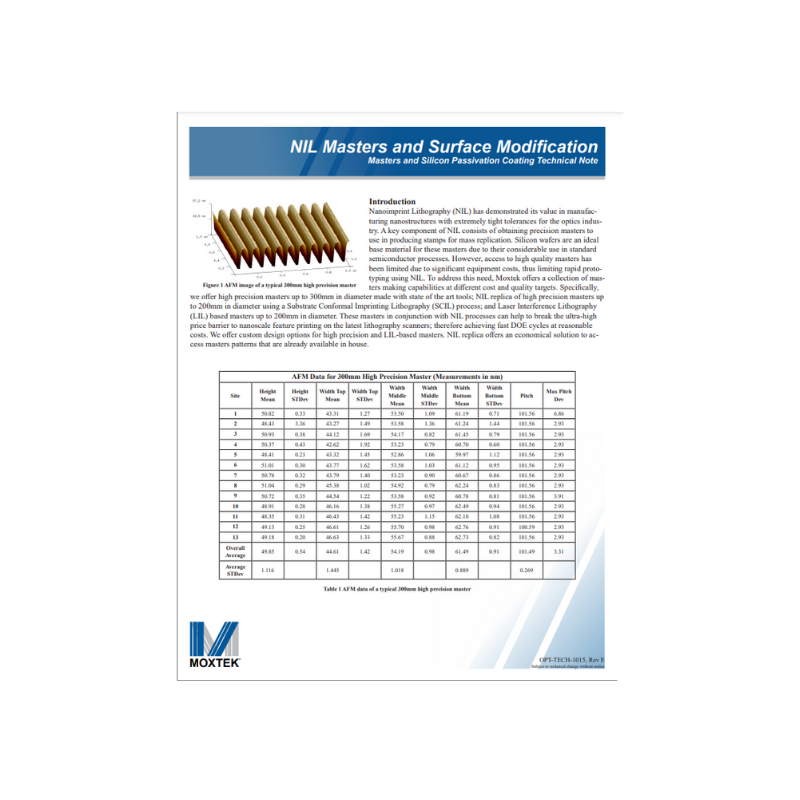

- Minimum CD: 30nm

- Master Aspect Ratio: ≤ 2 (CD Height/Width)

- Master Wafer Type: Silicon (Preferred)

- Master Wafer Size: Ø300mm, Ø200mm (preferred) Ø150mm (acceptable)

- Residual Layer Thickness: 15nm < X < 25nm

- Substrate Detail: Ø200mm glass/fused silica/silicon/sapphire Thickness: 0.675mm to 1.8mm

- Resist Mask: Oxide-based sol gel, UV curable, or nano particle resist