- Features

- Specifications

- Videos

- Downloads

- Applications

- Related Products

- Back To Spectroscopy

- Back To Optics

- Back To Hyperspectral

- Back To Cameras

- Back To X-Ray

- Back To Light Measurement

- Back To Characterisation

- Back To Electron Microscopy

- Back To Magnetometry

- Back To Ellipsometers

- Back To Cryogenics

- Back To Lake Shore

InfraTec Electronic / Semiconductor Testing Solution – E-LIT

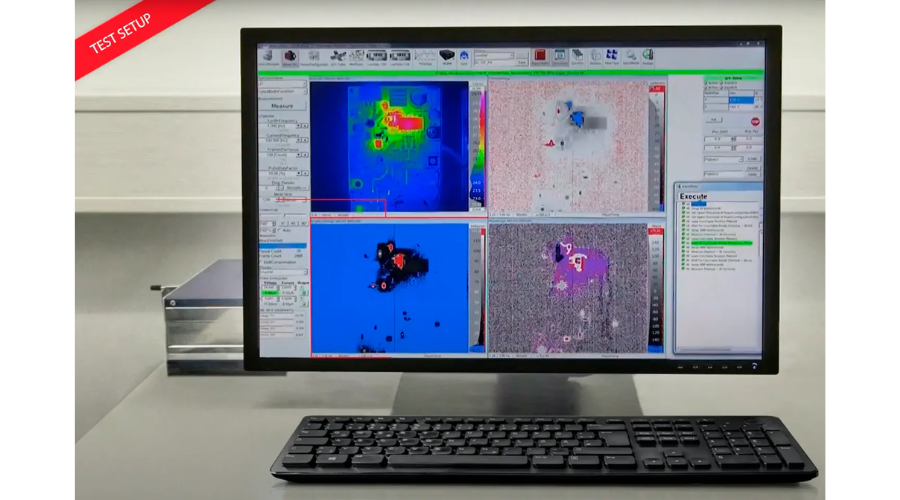

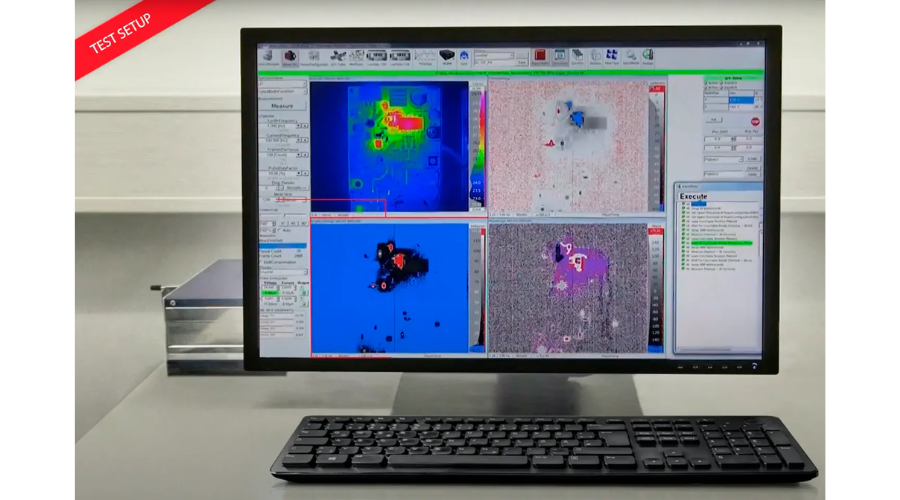

Modular Automated Test Bench

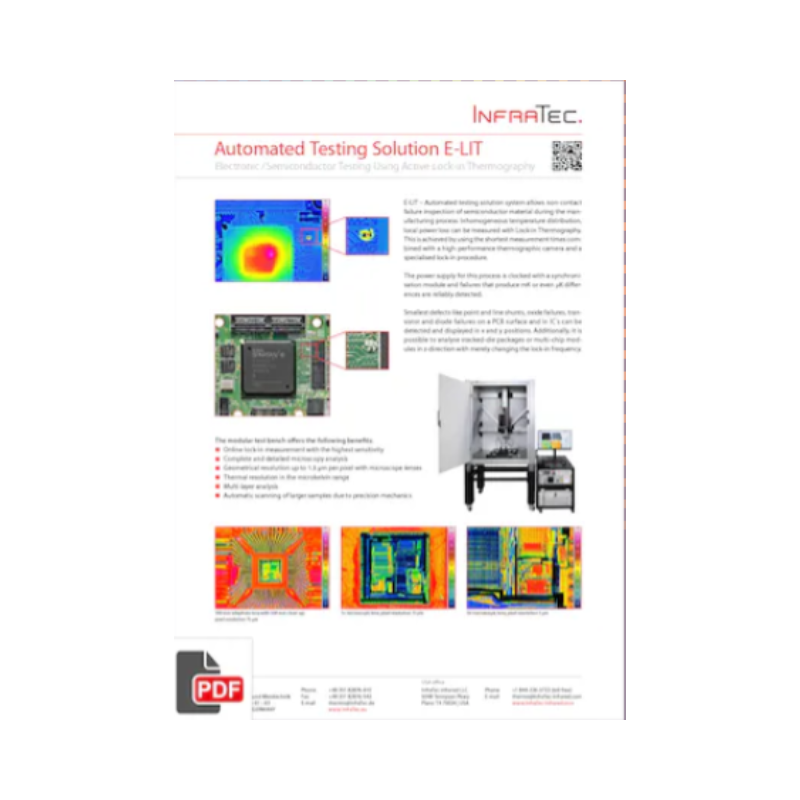

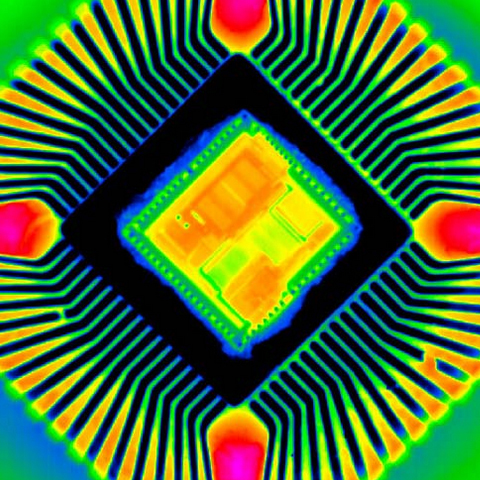

Automated testing solution system allows non-contact failure inspection of semiconductor material during the manufacturing process. Inhomogeneous temperature distribution, local power loss can be measured with Lock-in Thermography. This is achieved by using the shortest measurement times combined with a high-performance thermographic camera and a specialised lock-in procedure.

The power supply for this process is clocked with a synchronisation module and failures that produce mK or even μK differences are reliably detected.

Smallest defects like point and line shunts, oxide failures, transistor and diode failures on a PCB surface and in IC´s can be detected and displayed in x and y positions. Additionally, it is possible to analyse stacked-die packages or multi-chip modules in z-direction with merely changing the lock-in frequency.

FEATURES:

- Online lock-in measurement with the highest sensitivity

- Complete and detailed microscopy analysis

- Geometrical resolution up to 1.3 μm per pixel with microscope lenses

- Thermal resolution in the microkelvin range

- Multi-layer analysis

- Automatic scanning of larger samples due to precision mechanics

SPECIFICATIONS

Measuring chamber

| Infrared thermographic camera | High-end camera – ImageIR® or VarioCAM® HD head |

| Detector (cooled) | (1,280 × 1,024) / (640 × 512) IR pixels |

| Detector (uncooled) | (1,024 × 768) / (640 × 480) IR pixels |

| Spectral range | (2 … 5) µm or (7.5 … 14) µm |

| Infrared image frequency | Up to 355 Hz @ (640 × 512) IR pixels |

| Available lenses | 12 mm, 25 mm, 50 mm, close-ups, microscopes 1×, 3×, 8× up to 2 µm per pixel |

| Electrical excitation source | 4 Quadrant power supply or other special power supply e.g. Keithley |

Optional

- X, Y axis sample moving table

- Z axis for camera positioning and focus adaption

- Autofocus for camera

- Contact probes for 4 point measurement

Evaluation unit

| Dimensions | (560 × 670 × 840) mm (W × H × D) |

| PC | 19″ industry PC |

| Power supply | 230 V AC / 110 V AC |

| Weight | 60 kg (incl. PC)* |

Test bench / rollable base

| Dimensions | (1180 × 1280 × 800) mm / (1150 × 750 × 800) mm (B × H × T) |

| Weight | 80 kg / 150 kg |