Our partners at Moxtek have announced two new capabilities:

- Hard protective coating

- Fabrication of custom micro and nanostructures via Nanoimprint Lithography (NIL)

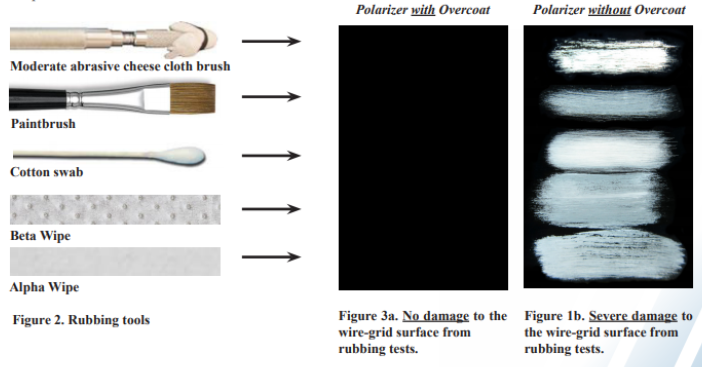

Hard Protective Coating forWire-Grid Polarisers

This is coating can be applied to Moxtek polarisers to increase their durability and protect the critical wire-grid structure

Key Features:

- Moxtek has developed the proprietary Overcoat coating to protect the wire-grid surface.

- This coating provides mechanical support and durability to the wire-grid surface allowing for gentle wiping and cleaning.

- The Overcoat is also thermally stable at temperatures up to 300°C for over 1,000 hours with minimal performance impact.

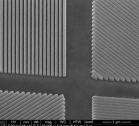

Fabrication of custom micro and nanostructures via Nanoimprint Lithography (NIL)

Moxtek offers state of the art NIL volume manufacturing on 8-inch glass and silicon wafers.

Based on data from 10,000 processed wafers, we have shown stamp life well in to the 500 to 750 print ranges with some life time test up to 1300 prints, and minimally maintained critical dimension (CD) of 30nm.

The foundry service includes:

- master design and manufacturing

- stamp making

- imprint prototyping

- mass production

Moxtek provides DOE and cycles of leaning for print optimisation along with statistical process control (SPC) monitoring of post print CD repeatability.

The Moxtek linear polarisers and beam splitters are constructed completely from inorganic materials. This allows them to be more tolerant to high temperature or high photon flux environments compared to organic polymer film alternatives. This is especially important in UV curing and projection display applications. The company has been innovating since 1986 and has now become a leading supplier of advanced nano-optical and X-ray components for display electronics, imaging and analytical instrumentation.