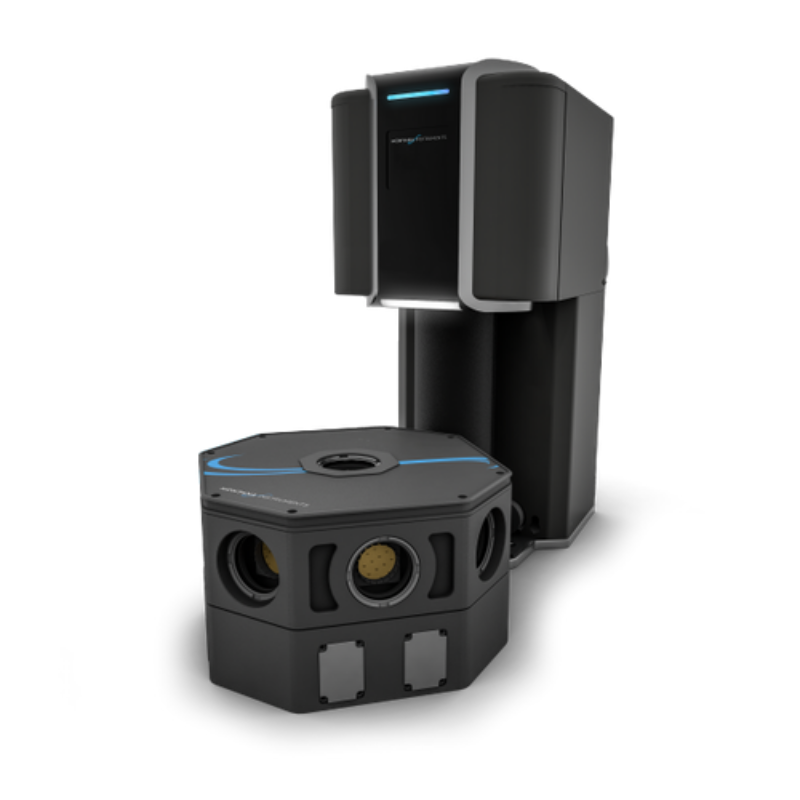

Rental Imaging Cameras Now Available

Click here to discover more

Click here to discover more

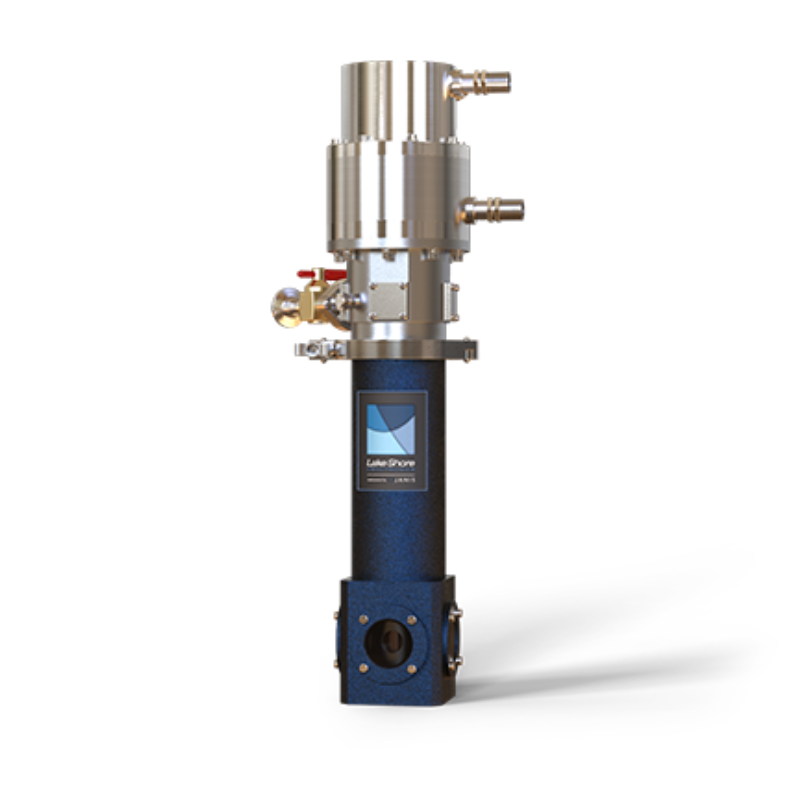

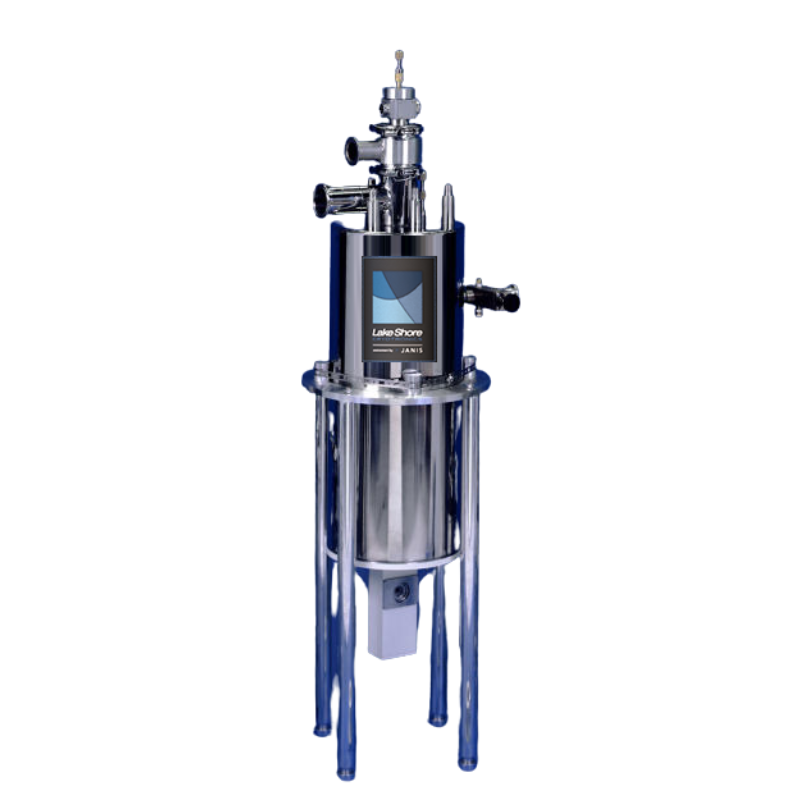

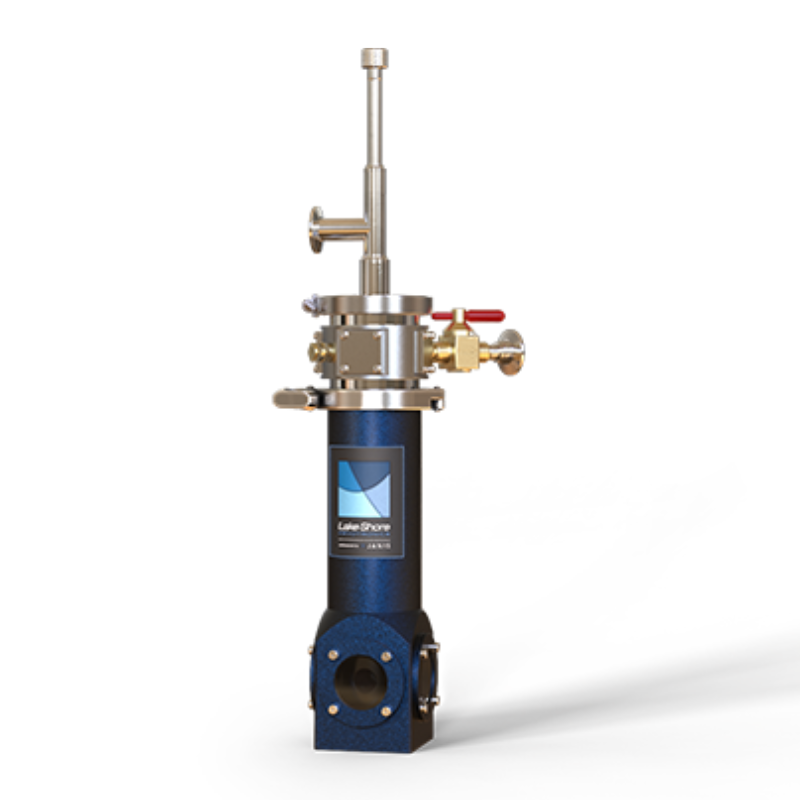

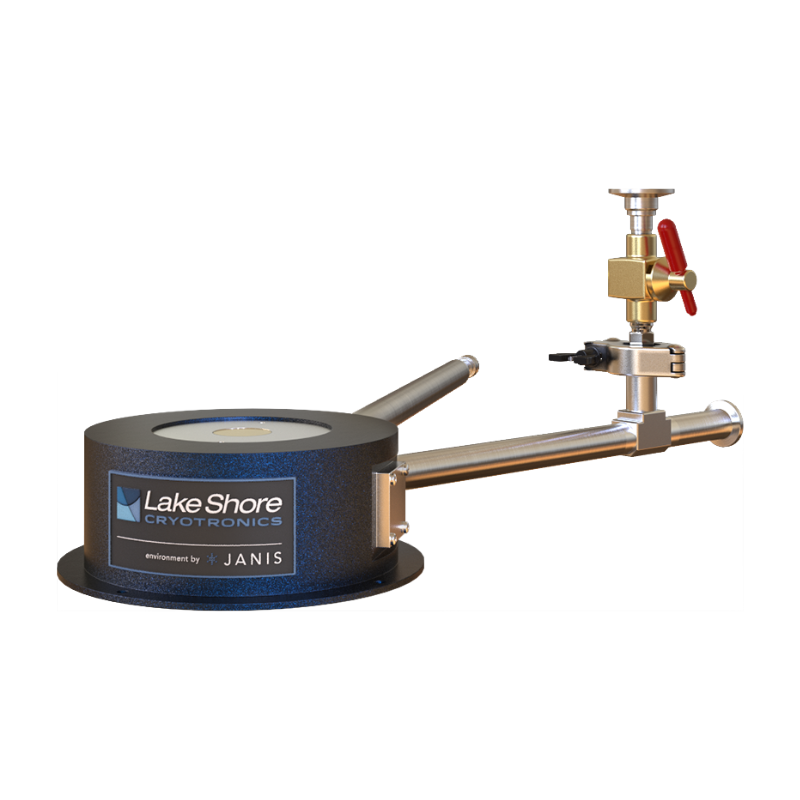

Cryogenics

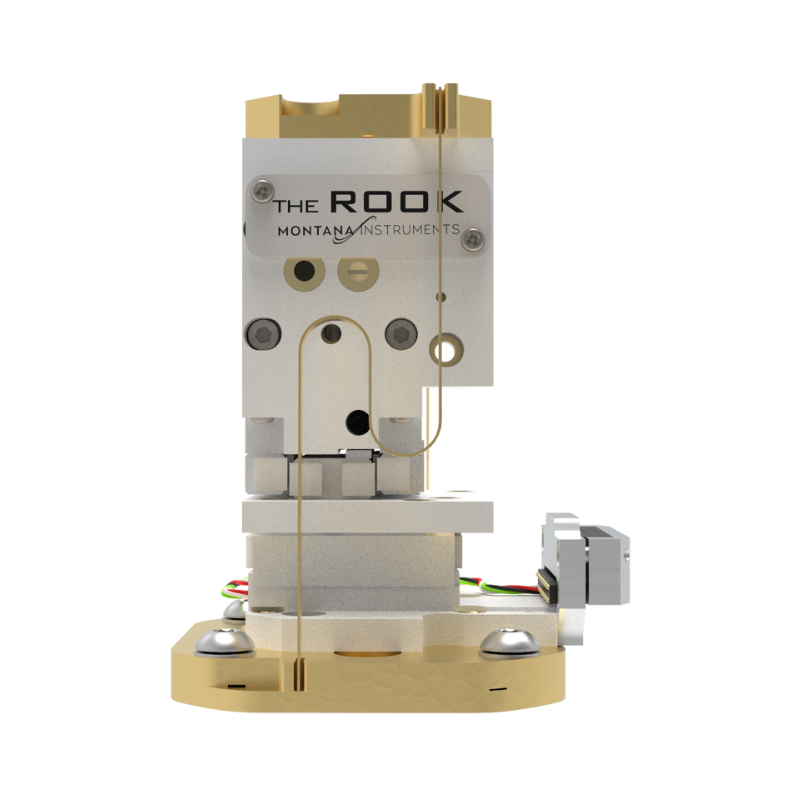

Low Temperature Cooling Systems

The range includes cryogenic instrumentation from Quantum Design, Montana Instruments, Lake Shore Cryotronics / Environment by Janis

We offer closed-cycle optical cryostats with a GM cold head as well as cryostats based on pulse tube. Also available are lab scale helium liquefiers and helium gas purifiers together with cryogenic temperature controller and monitors.

Cryogenic Instrumentation Brochure

Cryogenics Magazine

Quantum Design UK and Ireland (QDUKI) is proud to bring you this magazine with information about new products, interviews and case studies that have been produced using products that we offer.