Use complementary information from SEM and AFM to image complex samples like razor blades with nanometer precision.

In today’s competitive market, delivering high-quality products is essential for manufacturers seeking to build trust and loyalty among consumers. The shaving industry has experienced significant growth over the past century, driven by increasing demand for effective, convenient, and aesthetically focused hair removal solutions. As shaving remains the most accessible and cost-effective form of hair removal, consumers expect razor blades that provide precision, comfort, and reliability. For manufacturers, achieving this means ensuring that razor blades are consistently sharp, properly angled (blade curvature), and designed with the optimal number of facets (angles as the blade nears its edge) for the intended purpose. High-performance blades not only enhance the shaving experience but also strengthen a brand’s reputation for excellence. By adopting cutting-edge production techniques and quality control measures, manufacturers can stay ahead in the market and deliver products that meet the evolving expectations of modern consumers.

Challenges to Solve

One of the primary challenges of razor blades for shaving is that there isn’t a standard size for everyone. Different blades might be more effective depending on the sensitivity of skin, type of hair being shaved, and fineness of cut required. These differences include: the type of razor the blade is being used with, the material the razor blade is made from, and the coating applied to the blade. Additionally, the sharpness (blade edge thickness) and number of facets of the blade are also important to control the closeness of the shave. In the situation of coatings and blade edge thicknesses, characterising a size scale ranging from micrometers to hundreds of nanometers is required. For blade curvature, which can impact the blades rigidity and chatter (the vibration of the blade towards and away from the skin), observations can be of the order of 10 nm whereby a blade with 10 nm curvature is considered “razor sharp”.

Current Solution

Sputter Depth Profiling (SDP) is currently utilised to determine the relative coating thickness on razor blades due to its ability to record chemical information as a function of depth. It is a very high-resolution technique able to measure less than 1 nm resolution and is generally used with other techniques such as Scanning Electron Microscopy (SEM) to obtain roughness information. While most razor blades are made of stainless steel, some are made of carbon steel — which is susceptible to rust. Through observation with SEM, rusting and other surface impacts and damages can be observed for the purpose of monitoring coating integrity as well as the uniformity and quality of blade sharpness. While SEM can image any defects or damages on the blade surface, as well as observe any defects or damages to the blade edge, Atomic Force Microscopy (AFM) provides detailed quantitative information about the uniformity of the blade coating and curvature by gathering topographic information of the blade edge.

Our Approach

The FusionScope allows us to obtain both SEM and AFM information of the razor blade at the same time, within the same environment. This reduces sample preparation as well as overall measurement time. Additionally, we can utilise the SEM to find a location of interest more accurately and precisely than optical microscopy, found in most conventional AFMs, and then use the Profile View of our system to accurately position the AFM tip on the measurement position of interest. This can both reduce any potential tip-sample interaction, removing the chance of tip-sample collision and therefore potential blade coating or tip damage, as well as allow us to position the AFM tip very precisely on the razor blade edge faster than in conventional AFMs.

Data Analysis

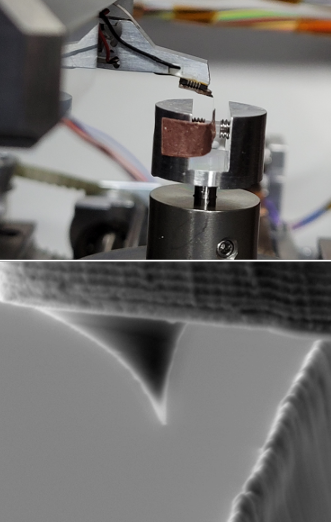

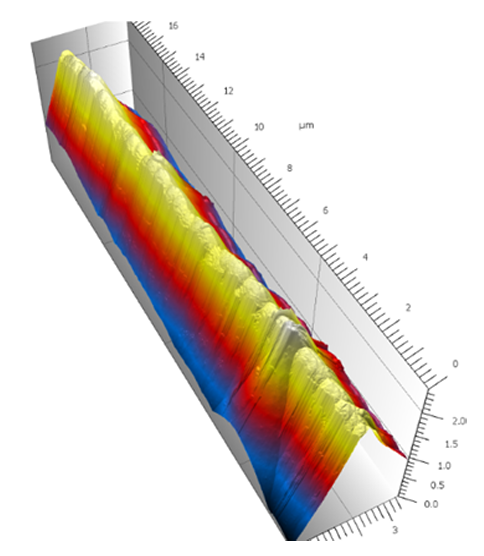

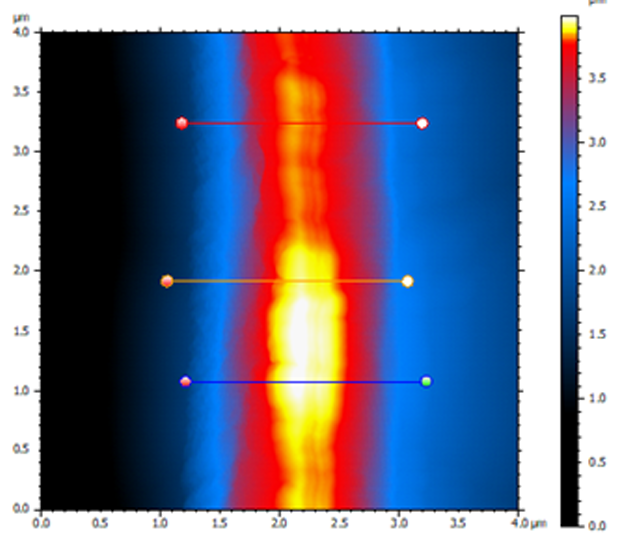

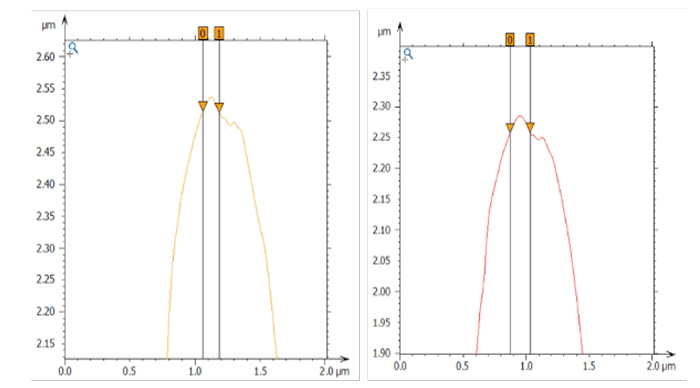

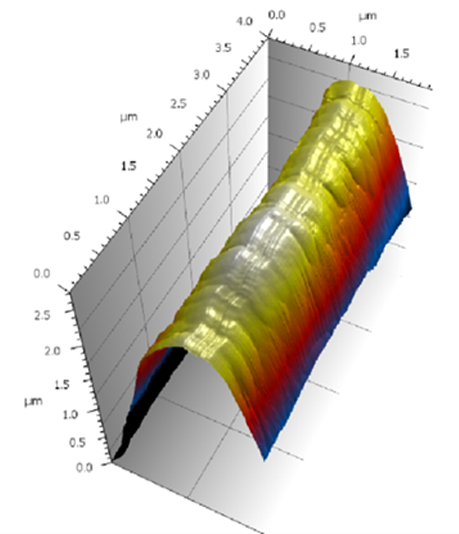

A commercially available razor blade serves as the sample in this Application Note. The unmodified blade was installed in the sample holder and grounded to avoid electrical charging by the electron beam. The aim is to image the surface of the blade with the AFM and, in particular, to determine the radius of the blade edge. The measurement comprises several steps: the coarse positioning, the fine positioning, the approach of the tip and finally the measurement of the topography. The coarse positioning is done using an optical camera. First, the cantilever tip is moved to the eucentric point of the FusionScope. Since this point is already known, this positioning does not require much time. The razor blade is then moved to within about one millimeter of the cantilever tip (Figure 1, top). The SEM is used for fine positioning. The movement of the tip and the top of the razor blade can be observed live. This enables positioning with an accuracy of significantly less than 1 µm. In the next step, the cantilever tip is moved to approach and the analysis of the 3D topography executed (Figure 1, bottom). It is possible to create rectangular sections of the topography and adjust the measurement parameters during the measurement. The movement of the cantilever tip over the sample can be followed live with the SEM at any time. A sample section of 5 µm x 24 µm across the blade edge is thus recorded with nanometer accuracy.

With the help of the fine positioning made possible by the SEM, different areas on the razor blade can be quickly selected and measured. In this way, variations at different points of the same sample can be examined in an easy and straightforward manner. Different material properties, such as a coatings applied to the razor blade, can be compared. An important parameter is the radius of the razor blade, as well as the roughness of the surface.

Representative Data

The measurement of the 3D surface topography makes it possible to identify unusual features on the blade surface; for example: the “double groove” seen in Figure 5. In addition, individual line scans on the blade edge can be extracted which enables the calculation of the exact blade radius (Figure 4). In Figure 2, the end radius of the blade is determined at each section, averaging a value between 60-80 nm in the sample’s sections.

In conclusion, FusionScope enables users to measure complex samples — even those that are difficult to access by conventional AFM. The combination of the complementary strengths of AFM and SEM enables an easy workflow to position the cantilever on the blade edge and analyse the 3D topography and the blade radius.

Easy to use Correlative AFM with SEM Microscopy Platform

FusionScope is an easy-to-use correlative microscopy platform designed from the ground up to add the benefits of SEM imaging to a wide range of AFM measurement techniques.

To learn how the FusionScope can help in your industrial application, contact Dr. Luke Nicholls by email below or call (01372) 378822.