With more than 30 models, InfraTec offers a variety of infrared camera models for all application areas of thermal imaging. InfraTec also expands its expertise in the field of thermography by participating in various research projects. Our partners are both national and international scientific institutions and companies from a wide range of industries.

Applications

Additive Manufacturing

By in-line monitoring of thermal process parameters, infrared cameras from InfraTec support the optimisation of additive manufacturing processes.

In additive manufacturing, temperature is one of the factors on which the quality of the final product depends. Thermal imaging cameras record temperature developments and deviations in real time and enable rapid intervention in the ongoing process.

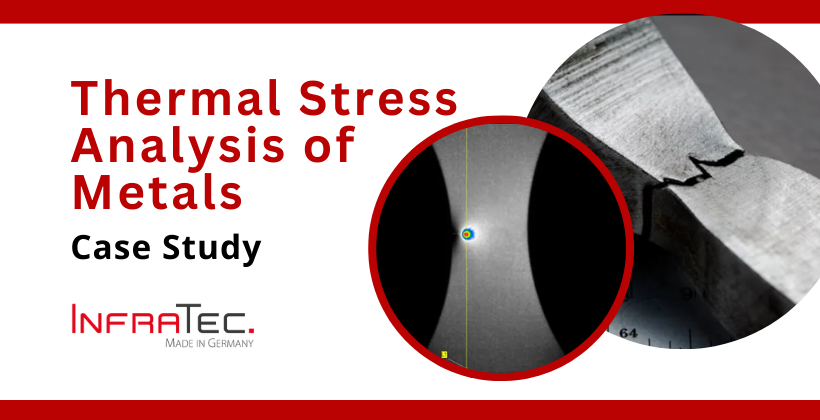

Material Testing

Save time and costs by non-destructively testing components with infrared camera systems by InfraTec.

Stress changes during tensile testing provide information about material properties of metals such as tensile strength. With the help of thermographic cameras metallic solid bodies can be tested for such stress changes.

Active Thermography

Make use of active thermography for non-destructive and contact-free material testing, for both automated inline and offline solutions.

Various methods of active thermography like Lock-In Thermography and Pulse Phase Thermography are imaging procedures that perfectly suit for contact-free and non-destructive material testing. In connection with high-resolution infrared cameras, they allow for quick detection of material defects and open up new possibilities in research, development and quality assurance.

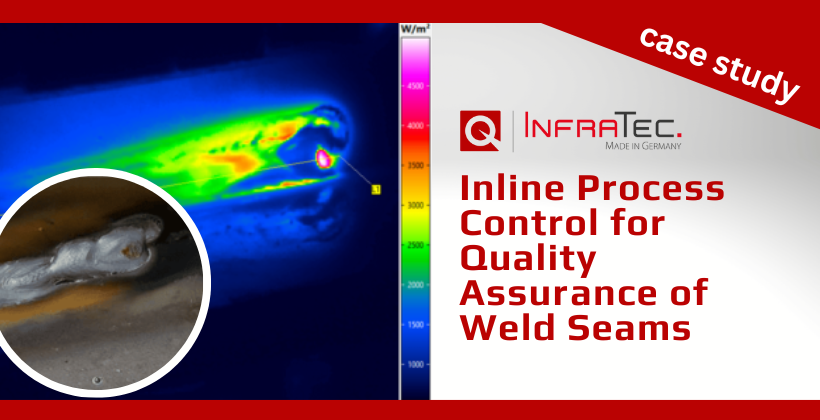

Bonding and Sealing

Users can utilise infrared cameras during bonding and sealing to monitor and control various technological parameters.

Miscellaneous welding tasks in steel constructions currently have a low degree of automation, resulting in a high amount of manual work and employee-dependent quality levels. Read this Case Study from InfraTec looking at the inline process for quality assurance of weld seams.

Inspection of Mechanical Assemblies

Thermography reveals irregularities in heating of mechanical components in time.

Lasers are extremely versatile tools in industry and manufacturing technology. Due to their flexibility, they serve as a key technology for implementing the goals of industry 4.0. Although laser cutting and welding are nowadays regarded as turnkey technologies, the majority of laser applications, for example joining of hybrid materials, 3D printing or ultra-short pulse processing, still require considerable research and development.

Events on Demand

InfraTec offers a diverse selection of free online events every year. In their topic-specific, compact presentations, various speakers from the respective specialist areas present the possibilities and special features of different applications.

Some online events are presented here for you to choose from. To watch an event on demand, InfraTec only needs some data from you. You will receive the link to the webinar by e-mail.

Optimising Additive Manufacturing Technologies Using Thermography

- Additive manufacturing: definition, benefits, types, presence and future

- Fields of application for thermography in additive manufacturing

- Challenges in additive manufacturing of metals

- Use of thermography to improve manufacturing technologies

- Technical requirements for IR cameras in additive manufacturing

Efficient Material Testing – Non-destructive and Contactless

- Theoretical background – mechanical force, stress and temperature Methods for analysis

- Examples from practice with application samples – elastic periodical load test and fatigue test

- Short overview about InfraTec products

Laser Technologies Benefiting from Infrared Thermography

- Technical Lecture from Federal Institute for Materials Research and Testing (BAM)

- Overview of laser applications and types

- Fields of application for thermography in laser technologies

- Technical requirements for thermographic cameras, software and accessories for successful implementation in in laser technologies

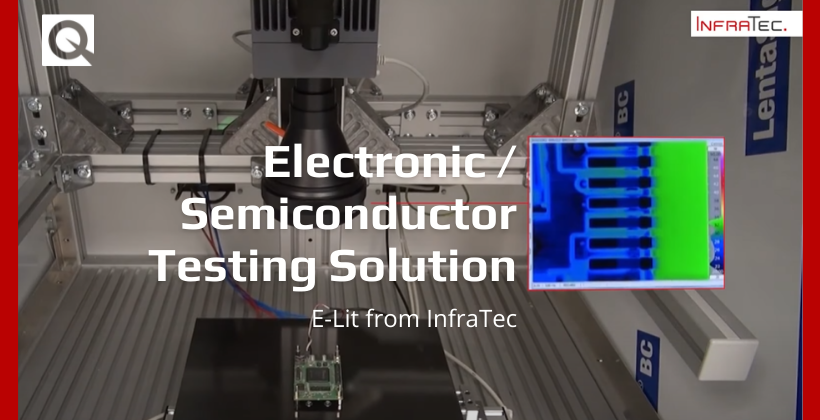

Thermography Solutions for Power Electronics – Precise, Non-contact and High-speed

- Challenges of electronics testing

- Improvement of electronics design and thermal management by understanding heat

- Thermography in the various phases of electronics development and production

- Important and relevant selection criteria

Unlimited Flexibility in Thermal Imaging with Zoom

- Motorised zoom lenses in general

- Radiometric zoom lens specialties

- Specific motorised zoom camera advantages

- Applications for infrared zoom cameras in detail