The recent outbreak of Coronavirus has left many hospitals and healthcare facilities scrambling to extend the use of their PPE through disinfection. To that end, many are looking at using UV-C light in order to disinfect materials and surfaces of viruses and microbes .

ILT does not make any recommendation or referral on if or how to use UV light for disinfection purposes, or publish standards or procedures for proper disinfection. With 55 years in the industry, however, many healthcare professionals are turning to ILT as one of the most trusted and experienced equipment manufacturers and calibration labs for UV measurement systems.

For those searching for light meters that measure UV light, you’ve have probably found a number of different meters at a number of different price points. To the “untrained” eye, these meters can look the same. So why are some meters a few hundred dollars while others are a few thousand? Well as often is the case, you’re getting what you pay for.

To begin let’s briefly explain what a light meter does and how it functions. Most light measurement systems include a sensor that, when exposed to light, generates current or voltage proportional to the amount of light received. The light meter takes the incoming signal and converts it to a light-level reading in the appropriate units, e.g. lux, foot candles, watts, watts per square centimeter, etc. But not all systems that read out in the same units have the same quality of components or calibration behind their values.

The below will highlight what specifications set expensive meters apart from their cheaper counterparts.

Linearity

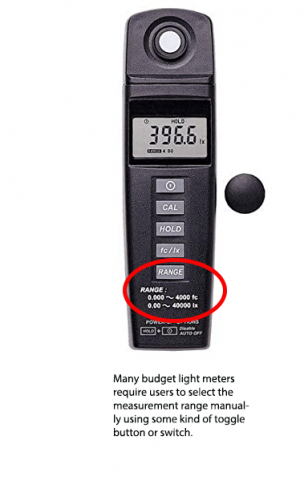

UV meters are often noted as being able to measure a wide range of intensities and dose. Some require range selections due to lack of linearity of the meter and/or the sensor materials. While others simply ignore or are unaware of the lack of linearity of their systems altogether. Linearity is a critical factor in offering stable and accurate light measurements in all ranges of intensities. Non linearity will result in greater errors when the intensity changes. An auto ranging, linear light measurement system is the only way to ensure accurate measurements over the full operating range of the UV meter.

Versatility

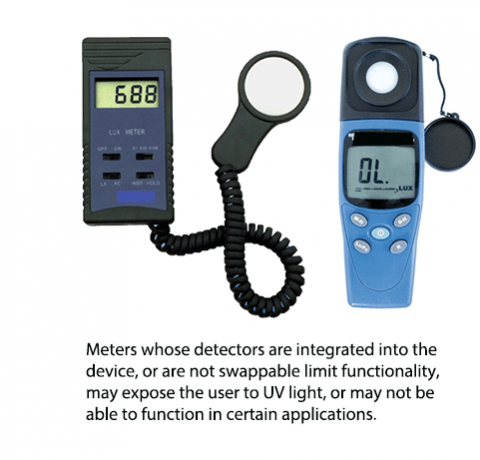

When looking for a meter that will suit all of your current and future needs, having a solution that allows you to swap out filters, input optics and or detectors and calibration factors can be an important feature.

Many low cost meters do not allow for component swapping because the detector is hard-wired or built in, as are the sensor components. Why is this a limiting factor? As with most things, one size often doesn’t always fit all. If you purchase a meter now for UV lamps and later add LED’s, you may be forced to purchase a costly new meter and sensor rather than just changing out a sensor, filter or calibration factor. As new, more powerful lamp designs emerge there is a great benefit to adding attenuation to an existing sensor rather than replacing your entire system. New technologies may also include new wavelengths such as changing from 254 nm to 222 nm lamps.

A Lamp’s output can change over time and the ability to measure lower signals for longer periods of time may arise. New applications may require a completely different sensor sensitivity range. Selecting a more diversified meter is future proofing your investment. It’s like having the capability of multiple meters in a single device.

Lastly, if you are looking for maximum versatility, select a meter whose detectors offer remote measurements, in addition to supporter cal factors, sensors, filter, or optic changes. These detectors may be at the end of cables that are many feet long or operate as stand-alone devices.

Spectral Ranges and Filtration

The spectral sensitivity range of a UV meter is determined by the component material of the sensor. Due to limited material available for UV sensors, often silicon or GaAsp diodes are used. These sensor start out with a very broad range of sensitivity and are not Solar blind. This means that even when filtered, there can be leakage from Visible and NIR light that are not portrayed in the manufacturers sensor spectral curves. This is because the filters typically block 2 to 4 decades of light which makes the curves showing 1 to 100% a bit misleading. With many light meters, it is possible to correct for the leakage by doing an ambient zero. In some sensors it is possible to add additional VIS or IR blocking for applications where the amount of visible light is more than 100 or 1000 times stronger than the UV levels.

Silicon Carbide and Vacuum phototubes are a good alternative as they have no visible and IR sensitivity, however they may also face similar problems if the ambient environment or light source under test also contains UVB and UVA.

It is always best to determine whether your lamps total output versus the portion of the spectrum that must be measured to be certain the blocking of the sensor and filter are adequate and are both passing and blocking the correct ranges and amount of light.

Incorrect sensor/filter selection on a broad band lamp can actually cause readings that are either too high or too low. If the readings are too high, shorter exposure times may be used causing an incomplete decontamination of germs or ineffective cure. Readings that are too low can cause product damage due to over exposure. Both of which can be costly errors.

Calibration

Perhaps the most important feature of a meter is its traceable, lasting calibration. What sets quality meters apart from the rest is a combination of the quality of the components, and the quality of the calibration that ensures the conversion from volts or amps to the equivalent light level reading such was watts or joules, is accurate. Without an accurate calibration the readout is simply a relative value, and the units on the meter may as well list volts, amps, relative, or percent. Accurate, accredited, traceable calibration means the readings on the display have value. In short, the readings can be trusted.

So how can you tell a meter comes with a good calibration? Look for meters that say they have NIST traceable and/or ISO17025 accredited calibrations. These two separate standards ensure traceability and working standards for calibration and quality assurance of policies and procedures respectively. Ideally the meter will have both.

Conclusion

If you’re using a meter to measure UV light, chances are you need to have assurance that the data you are receiving is accurate. Using a meter that is inaccurate, or whose accuracy is uncertain can put the safety of your personnel at risk and can cause unnecessary maintenance or premature replacement of costly lamps.

If you are relying on that light to inactivate pathogens or initiate a reaction critical to a process, then reliability and accuracy are paramount. It stands to reason that there is significant investment in light measurement systems that deliver on those assurances. Using an inaccurate UV meter could well end up costing more than the price difference between a budget meter and a high quality, traceable UV measurement system.