Originally produced in MEPCA magazine, interview by Oliver Batt

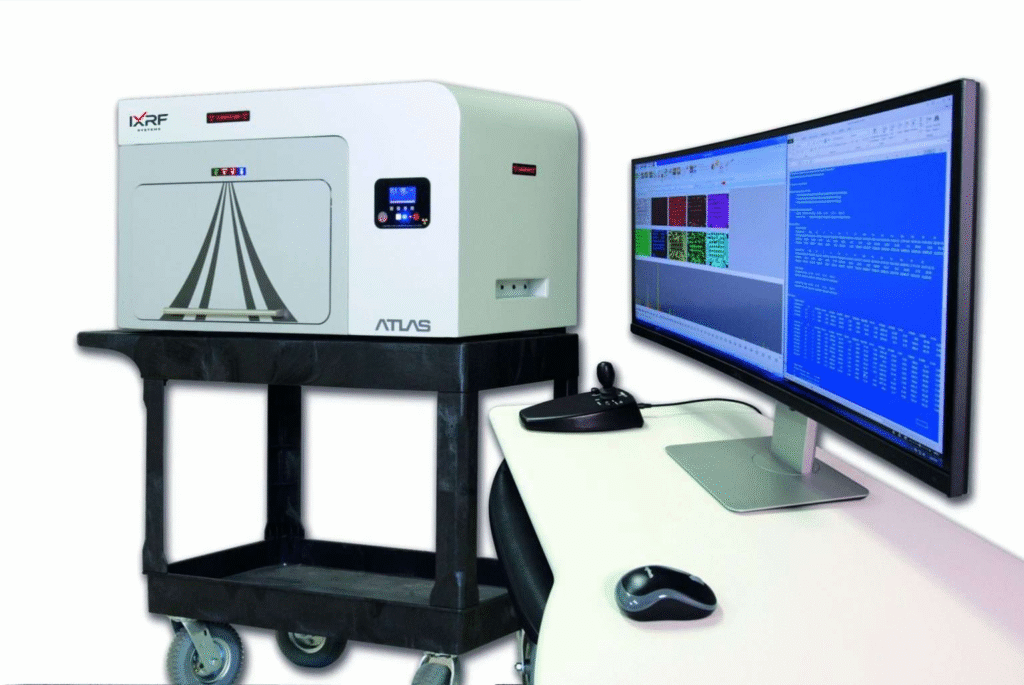

Quantum Design UK and Ireland introduces IXRF, designer and manufacturer of world-class scientific measurement instruments. Here, IXRF explains the wide applicability of microXRF systems, from QA in manufacturing to determining the material composition of artefacts on archaeological sites.

Led by a team of experienced scientists and engineers, IXRF has distinguished itself as an innovator in the field of high-end X-ray microanalysis instruments. Here, IXRF’s experts satisfy our curiosity about the many fascinating applications of their leading microanalysis technology.

1. How are IXRF’s microXRF systems commonly applied in the processing industry?

IXRF’s microXRF systems are widely used across the processing industry for rapid, non-destructive elemental analysis. They are essential for quality control, measuring coating thickness, detecting contamination, and verifying raw materials. Industries such as metal processing, petrochemical production, electronics, and ceramics rely on IXRF’s systems to ensure product consistency and compliance with strict material specifications. Our microXRF technology enables the analysis of a wide range of sample types, including bulk materials, thin films, powders, and even irregular surfaces, providing a flexible and efficient solution for industrial process monitoring.

2. In addition to its range of innovative products, how else does IXRF support its customers?

At IXRF, we believe that innovation should be matched with exceptional support. Our team offers comprehensive services including expert application development, personalised training, on-site installations, and dedicated technical support. We work closely with customers to tailor solutions to their specific needs and provide ongoing consultation to optimise performance. Additionally, we offer free software upgrades for life, ensuring that users always have access to the latest capabilities. Our commitment to partnership ensures that customers are supported at every stage—from initial consultation to long-term system optimisation.

3. How are IXRF’s microXRF solutions applied to the recycling and waste industries?

IXRF’s microXRF technology plays a crucial role in the recycling and waste industries by enabling rapid, non-destructive elemental analysis of complex, heterogeneous materials. A growing application is the recycling of used solar panels, where our systems are used to identify and quantify valuable elements such as silicon, silver, and lead. By providing precise compositional data, microXRF helps recyclers efficiently recover materials that can be reused in the manufacturing of products such as glass bottles, electronic components, and even new photovoltaic devices. Our solutions enhance material recovery rates, reduce environmental impact, and ensure compliance with regulatory standards—all while handling the challenging variability found in post-consumer waste streams.

4. To date, what is the most interesting or unusual custom application of IXRF microXRF analysis?

One of the most fascinating custom applications involved analysing ancient artefacts recovered from archaeological sites. Our microXRF system was used to determine the elemental composition of rare coins, ceramics, and pigments without damaging the priceless materials. This allowed researchers to uncover historical trade routes, manufacturing techniques, and even authenticate artefacts—all while preserving their integrity. It’s a testament to the versatility of IXRF technology: from cutting-edge industrial quality control to unravelling the mysteries of history, our instruments empower users across a stunning range of fields.

Do you want to discuss your application or upcoming project?

Get in touch with our Dr. Luke Nicholls, by email below, or call (01372) 378822.