“Both ellipsometry and thermal analysis are fundamental characterisation tools in the study of thin-film materials. J.A. Woollam has teamed up with Linkam to bring precise temperature control to its ellipsometry instruments.”

Linkam Scientific Instruments, Tadworth, Surrey, UK

Thin films can be used to modify the optical characteristics of a surface, its electrical conductivity, its hardness or lubricity, its corrosion resistance, and its chemical inertness. It is important to understand how these properties are affected by temperature. Some materials even go through a phase transition at specific temperatures that greatly alters their optical properties. J.A. Woollam’s range of instruments provide accurate thin-film characterisation, which can be further enhanced by studying the material’s temperature dependence.

The knowledge of J.A. Woollam’s dedicated scientists and engineers has been combined with Linkam’s expertise in temperature-controlled stages to form a close partnership. By adapting its market-leading heat stages for J.A. Woollam’s custom ellipsometry instruments, the partnership provides thin-film researchers with tailor-made, temperature-controlled ellipsometers for a broad set of applications.

What is Ellipsometry?

Ellipsometry measures the change in polarisation state of a light beam reflected or transmitted from a material structure. This measurement is used to characterise the thin-film and bulk- material properties. Ellipsometry can also characterise composition, crystallinity, roughness, doping concentration, and other material properties associated with a change in optical response.

The application that put ellipsometry “on the map” was its ability to measure nanometer-scale layers used in microelectronics, but the use of this technology has since expanded to research in physical sciences, semiconductor and data storage solutions, flat panel displays, communication systems, biosensors and optical coatings.

This widespread use is explained by an increased dependence on thin films in many areas and the flexibility of ellipsometry to measure most material types including dielectrics, semiconductors, metals, superconductors, organics, biological coatings, and composites.

Ellipsometry measurements are perfect for thin-film thickness, where the wavelength of the light beam acts as a “nanometer- scale ruler.” The thickness is obtained from the interference between light waves reflecting from the top surface and those that have travelled through the film. The light experiences a phase delay while travelling through the film leading to constructive and destructive interference when recombined with the top-surface reflection. This phase delay is related to both film thickness and refractive index. In addition, reflection of light at each interface changes the polarisation state of the electric field as described by the Fresnel equations. The total resulting change in polarisation provides sensitivity to thin-film optical properties and thickness with a high degree of accuracy. Ellipsometry is typically used for films whose thickness ranges from a few nanometers to a few microns.

Compared with other optical technologies, ellipsometry has some distinct advantages. For example, intensity-based techniques, such as spectrophotometry, measure the number of photons captured from a light beam reflected or transmitted from a sample. However, this method relies on knowing the number of photons imparted onto the sample and the ability to capture all those that are reflected/transmitted, which is a considerable challenge. Additionally, any deviations in the system cause a loss of photons and are reported as inaccuracies.

Jeremy Van Derslice joined the Applications Group at J.A. Woollam in 2010, supporting customer applications development and service measurements using spectroscopic ellipsometry.

Jeremy explains how ellipsometry differs from other techniques:

“Ellipsometry measurements determine the change in polarisation that occurs as the probe beam interacts with the sample by comparing the change in magnitude and phase of the electric field oscillations in the p- and s- directions, which are respectively defined as directions parallel and perpendicular to the plane of incidence. The benefit is that we are not required to collect the entire beam to provide highly accurate measurements, and the phase information included in the polarisation provides ellipsometry a great deal of sensitivity to thin-film thickness.”

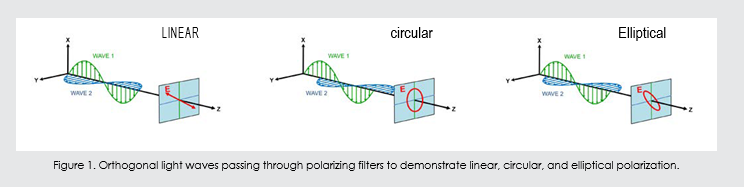

An easy way to visualize the polarisation state of light is to consider a few common cases as shown in Figure 1. When the p- and s- components of the light wave are in-phase, the resulting light will be linearly polarised; their relative amplitudes determine the resulting orientation. If orthogonal waves are 90° out-of-phase and equal in amplitude, the resulting light is circularly polarised. The most common polarisation is “elliptical,” one that combines orthogonal waves of arbitrary amplitude and phase.

Non-optical methods, such as profilometry, can also be used to measure thin-film thickness. Simple mechanical approaches such as this can measure thickness in the micron region but can be destructive and are not as sensitive in the nanometer or Angstrom range.

Quartz crystal microbalances (QCM) are another non-optical approach, which work by detecting changes in oscillation frequency when a material is deposited on the crystal. However, if the material has any dissipation parameters, QCM measurements can become difficult to use. Ellipsometry overcomes such challenges.

Custom, Fit-for-Purpose Solutions

J.A. Woollam ellipsometers are primarily used in the research and development (R&D) and quality control (QC) stages of thin- film development. Common examples include semiconductor processing, touch screens, flat panel displays, anti-reflection coatings on glass and bio-coatings on contact lenses or medical devices.

Jeremy explains the typical requirements of J.A. Woollam’s customers:

“Material developers need to ensure the thickness and optical properties of their films are appropriate for their application. For example, the touch-screen features built into many electronics require a transparent conducting oxide (TCO) layer like indium tin oxide (ITO) to sense the touch location on the device. The TCO layer is optically transparent and electrically conductive when engineered and processed correctly. Our ellipsometers are involved in the development stage of such projects, where researchers are searching for new materials with similar optical and electronic properties to ITO. We’re also involved in the quality control aspect where the ellipsometer monitors the film deposition to detect changes in film thickness and optical- related properties to ensure high-quality, high-yield production runs. This type of research is done by a variety of labs. We have instruments in many universities across the globe as well as in industrial research labs and production lines.”

A New Model is Established

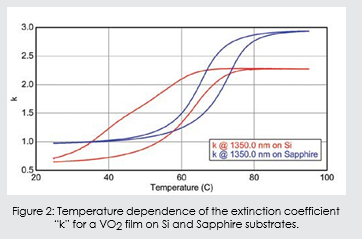

Many materials show considerable change in their optical properties as a function of temperature, and properties of thin films are often regarded as temperature dependent. For example, the transition of vanadium oxide from semiconducting to metallic properties can be shown by the monitoring the extinction coefficient at longer wavelengths, as shown in Figure 2. The nature of the transition was found to be dependent on the substrate used with the vanadium oxide film.

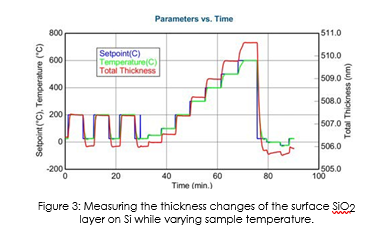

Temperature-controlled ellipsometry is a powerful tool for many applications, enabling the characterisation of a range of properties such as thermal expansion coefficients, which can be determined by monitoring thickness changes versus temperature.

Figure 3 shows variation in SiO2 thickness and temperature versus time, which can be used to extract the coefficient of thermal expansion.

Phase transitions and other transition temperatures can also be observed by monitoring temperature-dependent optical properties. J.A. Woollam customises its ellipsometers according to the needs of individual users, for example, by integrating temperature-controlled modules. This is particularly important during the R&D process so researchers can better understand how their materials behave as a function of temperature. Jeremy describes the considerations this requires: “When our customers are using ellipsometry for R&D, they are usually working on something brand new, often requiring uniquely configured instrumentation. We do our best to accommodate customisation requests from our customers and have built a business around that concept.”

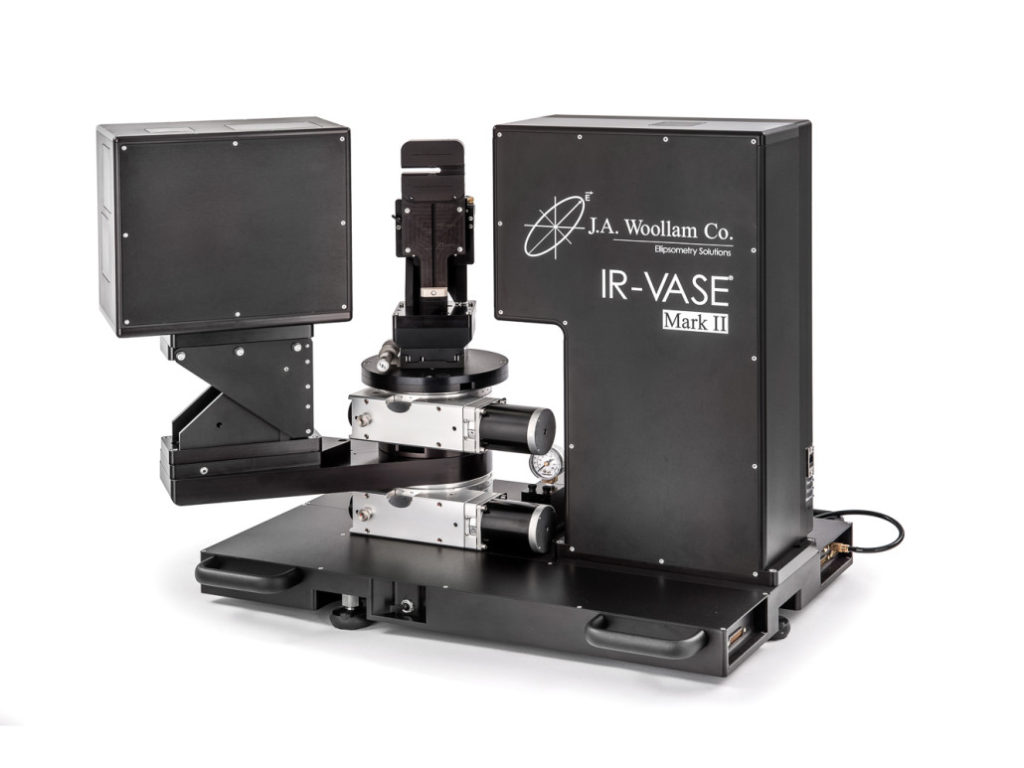

The modular design of J.A. Woollam ellipsometers facilitates the delivery of these novel configurations, and its relationship with companies such as Linkam allows thin-film researchers to test their materials in new ways. Linkam has modified some of its most popular temperature stages with customised optical adapters to facilitate use on an ellipsometer. The HFSEL600 provides temperature control from -195oC to 600oC and the TSEL1000 enables temperature-based ellipsometry measurements from room temperature up to 1000oC. Both stages are compatible with a variety of J.A. Woollam ellipsometers, such as the M-2000, RC2, and IR-VASE instruments. The Linkam heat stage adds precise control over a wide temperature range with the ability to incorporate gas purging as well as options for electrical probes and control of vacuum or humidity.

Samples can be quickly characterised by heating to within a few degrees of the required temperature at a rate of up to 150°C/min. and then slowed down to a few tenths of a degree per minute to closely examine sample changes.

The heat stage is a self-contained system with optical windows for ellipsometry measurements at an angle of incidence of 70°. It may also be operated as an open system with other angles of incidence. Jeremy comments on the integration of these systems:

“There are many applications where it becomes critical to measure optical properties at different temperatures in real-time. For example, this is necessary for materials used on satellites launched into space, where they are expected to function over a wide range of temperatures, or in silicon photovoltaic panels, where the quantum efficiency is temperature-dependent. The temperature-controlled ellipsometer stage from Linkam provides the ideal solution.”

The HFSEL600 is completely integrated into the J.A. Woollam CompleteEASE ellipsometry software package, which allows the temperature-dependent optical properties of materials to be determined.

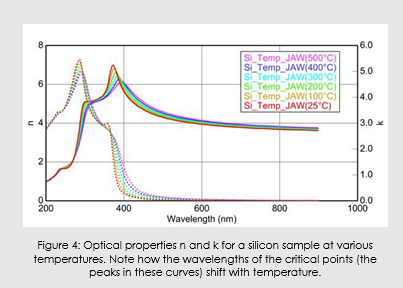

Figure 4 shows the optical properties of silicon as a function of temperature. Variations in the optical properties of silicon can impact device performance, so it is necessary to understand these changes during the design stage of a material system. The changing optical properties can be quantified using temperature- based ellipsometry measurements.

Collaboration with Linkam

J.A. Woollam and Linkam entered their collaboration in 2014.

One of the strengths of combining the expertise from each company is providing thin-film researchers with personalised, temperature-controlled ellipsometers. Jeremy comments on this value:

“Based on the modular nature of our product line and requests from our customers, we often ask Linkam to modify a configuration.” Linkam has continued to support us and our customers in adapting their temperature- controlled stages to suit J.A. Woollam ellipsometers – we ask a lot of them in terms of modifications, and they do an excellent job of accommodating our requests. Linkam’s products are highly reliable, which is something we were seeking to match the integrity of our overall package.”

Looking Ahead

Due to the wide-reaching applications of thin films, J.A. Woollam is continually assisting its customers in new areas. For example, although smart materials such as VO2 have been studied for some time, new ways to harness their electronic properties are now being discovered, including for neuromorphic computing and artificial intelligence, thanks to cutting-edge ellipsometry studies.

Combining ellipsometry with Linkam’s HFSEL600 heat stage for highly precise and accurate temperature control provides the ideal instrumentation to characterize these versatile materials. Duncan Stacey, Linkam’s Sales and Marketing Director, comments:

“As with many of our collaborations, the initial discussion with J.A. Woollam was about our standard product. It soon became clear that due to the flexible nature of J.A. Woollam’s ellipsometry systems, we could offer a much better solution for the customer by developing a customised solution. We brought our R&D teams together, and even though working on different sides of the Atlantic, we were quickly able to develop a product that fully met their needs. Both companies pride themselves on providing high performance and quality solutions to their customers. This has made the collaboration particularly easy and fruitful.”