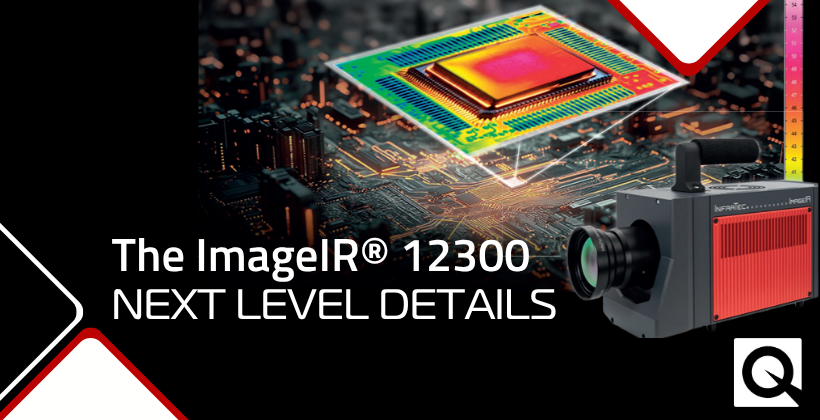

High-end Thermography Camera for Multifaceted Measurement tasks

The new ImageIR® 12300 from InfraTec is the radiometrically calibrated infrared camera with the world’s highest commercially available native resolution of 5.2 megapixel. The powerful top model of the ImageIR® series allows very fine structures on large area measurement objects to be resolved with unrivalled detail.

- High-performance photon detector with a native resolution of (2.560 × 2.048) IR pixels

- Pixel pitch of 5 µm

- Measurement accuracy ± 1 °C or ± 1 %

Due to its extraordinarily high resolution, the ImageIR® 12300 can always bring its strengths to bear when large area measurement ranges need to be analysed in detail and at once. The use of the camera provides a significant increase in efficiency and provides maximum accuracy by preventing geometrically induced measurement errors.

Modern production technologies demand that ever larger area objects be examined in a consistent and greater level of detail. The new ImageIR® 12300 satisfies this requirement due to a cooled high performance photon detector with a native resolution of (2.560 × 2.048) IR pixels and combines maximum geometrical and thermal precision in one camera.

Standard cameras with (640 x 512) IR pixels need at least 16 consecutive measurements to achieve the same level of detail as the top model of the ImageIR® series from InfraTec. Thereby a separate analysis of all 16 images may be required or merging them into a thermal image. Instead the ImageIR® 12300 renders the measurement not only in unrivalled image quality but in just one exposure which guarantees the synchronism of all data collected.

Integrated Trigger / Process Interface and Interfaces – Digitally Controlling of a Infrared Camera and External Devices

The internal trigger interface guarantees highly precise, repeatable triggering. Each of the two configurable digital inputs and outputs are used to control the camera or to generate digital control signals for external devices. In this way, for example, the operation of a printed circuit board and the interval of a measurement can be synchronised.

The selection of different camera interfaces allows the processing of analog data, such as the voltage directly through the camera and thus the insertion of this information into the thermal image data. Relevant variables can be included in the evaluations with the software, which makes it easier to draw conclusions about the causes of temperature changes.

Integrated Intelligence for More Independence

The ImageIR® 12300 is equipped with high performance electronics with impressive processing bandwidth. IR image data obtained can be recorded internally, analysed using implemented algorithms and used to control the high-end infrared camera.

The ImageIR® 12300 is designed for standalone operations completely without a PC. Alternatively, data can be output in real-time via various interfaces to high resolution displays as well as for external processing or storage. The integrated web interface allows for operation and remote control of the ImageIR® 12300 by smartphone or tablet.

Master the Most Complex Measurement and Inspection Tasks Yourself

High object temperatures or specific material characteristics of the measurement objects can make analysis with thermographic systems considerably more challenging. For such cases, InfraTec offers equipment with an optional aperture wheel and filter wheel. It is motorised and can be operated through the camera controller.

For example, if extremely high temperatures on objects are measured, the apertures weaken the respective radiation accordingly. With calibrated measurement ranges, a previously determined aperture is automatically selected and used for image recording.

If specific emission or transmission characteristics of the measurement object make the task more difficult, users can equip the aperture wheel and filter wheel of ImageIR® with filters. As a result, the camera’s range of use is expanded to cover the area of spectral thermography. In this way, transmission is prevented with thin foils and only their purely emitted radiation is recorded for temperature measurement. The wheel offers room for up to five spectral filters or apertures, so the thermography system can be adapted to target the measurement and inspection task on site.

Unlock the potential – discuss your application today

With our Technical Sales Manager, Dr. Luke Nicholls by email below or call (01372) 378822.