Measure your Film Thickness and Optical Constants by Ellipsometry

Here at Quantum Design UK and Ireland, we offer a wide range of spectroscopic ellipsometers, optimised for your particular application. Our partnership with the prestigious J. A. Woollam Company stretches decades and we have hosted their workshops and software course for over twenty years here in the UK.

The J.A. Woollam Company was founded in 1987 by Dr. John A. Woollam. Starting as a spin-off from the University of Nebraska, the company has rapidly grown to become a worldwide leader in spectroscopic ellipsometry. They have been perfecting their technology for over 30 years and have secured over 200 patents.

1. Spectroscopic Ellipsometry Batch Inspection at Covalent Metrology

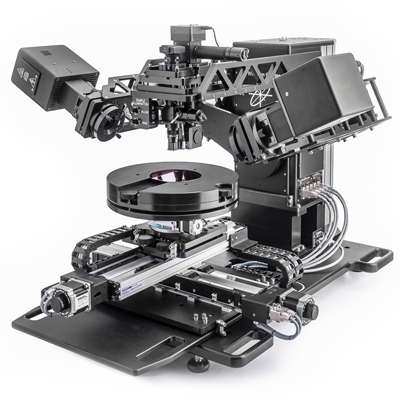

The J.A. Woollam RC2 ellipsometer is equipped with advanced automation features for both data collection and data analysis. It’s features like this that have helped cement ellipsometry’s reputation as being fast and relatively inexpensive for routine applications. To take advantage of these efficiencies and pass along the savings to our customers, Covalent Metrology is introducing a new low-cost batch inspection ellipsometry service aimed at measurement of full sets of sample replicates. This is a great option for anyone needing statistics on sample to sample variation on Si wafers, thin films, surface treatments, and more.

J. A. Woollam RC2 Spectroscopic Ellipsometer

Ellipsometer with dual rotating compensator technology

2. Cutting-Edge Applications Using Spectroscopic Ellipsometry – LITHOGRAPHY + COMPUTER CHIPS

Written by: Ron Synowicki and Jeremy Van Derslice

Electronic devices are continuously updated with noticeable performance improvements in every new generation of computer, laptop, smartphone, and gaming system. The technology driving these improvements includes faster processor chips, memory chips with larger capacity, and higher-resolution cameras and displays. In each case the circuitry in these chips and displays is smaller than the previous generation, allowing billions of transistors to occupy a small area of silicon and to be used for smaller, higher-resolution pixels for ultra-high-definition cameras and displays.

How is this accomplished? Optical lithography is a method of patterning circuitry or pixels directly onto a semiconductor or glass surface (a lithograph). The circuit pattern is first laid out on a glass plate called a photomask. The photomask contains areas that transmit light and others that reflect or absorb light. Ultraviolet light shines through the mask, and the circuit pattern focuses on the surface. The circuit pattern must be captured by the surface, which is accomplished by a layer called a photoresist. A photoresist acts like photographic film but is actually a thin film applied to the surface. Areas of the photoresist exposed to light from the mask become harder to etch (i.e., resist etching) than areas not exposed. To see the circuit pattern, the resist must be etched using wet chemicals, somewhat similar to photographic film processing.

Ellipsometry is used to determine the thickness and absorption properties of photoresist films for semiconductors, phase-shift layers on photomasks, and the thickness and optical properties of the red, green, and blue subpixel films in displays. Ellipsometry helps make sure these properties are uniform over the entire surface of the wafer or glass panel, which is always challenging since they keep increasing in size!

3. Latest J. A. Woollam Newsletter

4. 2023 Spectroscopic Ellipsometry Workshop and CompleteEASE Course Review

We recently held our 23rd annual J. A. Woollam Spectroscopic Ellipsometry Workshop and CompleteEASE software course.

IT WAS OUR BIGGEST YET, WITH RECORD ATTENDANCE!

The event was hosted with the Optoelectronics Research Centre (ORC) and the CORNERSTONE Silicon Photonics MPW (Multi Project Wafer) service at the University of Southampton. The ORC is one of the world’s leading institutes for photonics research. Click the link below to see photos, testimonials and user feedback from the events.

What next…?

To discuss your ellipsometry requirements and the solutions we can offer, please contact our Technical Director, Dr. Shayz Ikram by email or call (01372) 378822.