Using the J.A. Woollam IR-VASE II Ellipsometer for Stealth Coatings Applications

Stealth technology relies on reducing the detectability of objects—particularly to radar and infrared (IR) sensors—by manipulating surface materials to minimise reflected and emitted signals. A critical tool in developing and characterising such materials is the J.A. Woollam IR-VASE II spectroscopic ellipsometer, a sophisticated instrument designed for precise, non-destructive optical measurements in the infrared range (1.7 to 30+ microns). This capability makes it particularly valuable for assessing and engineering stealth coatings.

At its core, ellipsometry measures changes in the polarisation of light as it reflects off a surface. These changes are influenced by the material’s thickness, refractive index, and absorption properties—parameters that define how a coating interacts with electromagnetic waves. The IR-VASE II extends this technique into the mid-to-far IR spectrum, which is crucial because many surveillance and targeting systems operate in these wavelengths.

For stealth applications, one of the primary goals is to reduce infrared signatures. This can be achieved through coatings that absorb IR radiation instead of reflecting it, or by tailoring emissivity to blend with the background. The IR-VASE II allows engineers to precisely measure the complex refractive index (n and k values) across a broad IR range, enabling optimisation of materials to meet these stealth requirements. For example, by understanding the spectral absorption behaviour of a coating, one can fine-tune it to suppress reflection in specific IR bands used by thermal imaging systems.

Another key advantage of the IR-VASE II is its ability to characterise multilayer coatings. Stealth materials often involve complex stacks of dielectric and conductive layers to achieve desired electromagnetic responses. The ellipsometer’s high sensitivity and advanced modelling software allow users to extract detailed information about each layer’s thickness and optical constants — important data for ensuring the coating performs as designed.

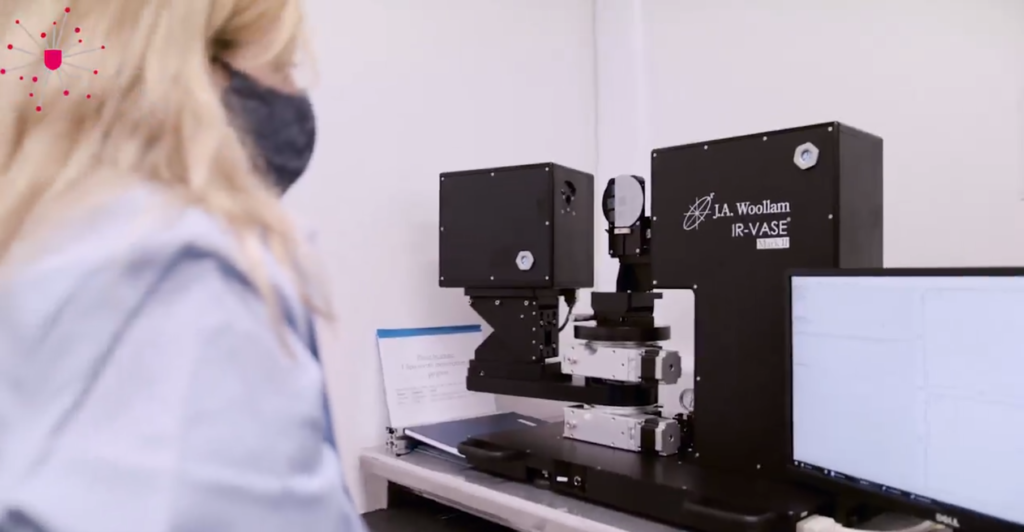

In addition, the IR-VASE II’s non-destructive analysis is ideal for quality control in manufacturing environments. Reproducibility and uniformity are essential in stealth coating production, and this instrument provides rapid, repeatable assessments without damaging the sample.

In summary, the J.A. Woollam IR-VASE II spectroscopic ellipsometer offers unmatched capabilities for stealth coatings research and development. Its ability to measure and model the optical properties of advanced materials across the infrared spectrum makes it an indispensable tool for defence and aerospace applications focused on minimising detectability in hostile environments.

Register for our Spectroscopic Ellipsometry Workshop – if there’s an application area you’d like us to include please let us know.

J. A. Woollam IR VASE II Spectroscopic Ellipsometer

Ellipsometer for thin films and bulk materials characterisation

To discuss your application…

…please contact our Technical Director, Dr. Shayz Ikram, by email below or call (01372) 378822.