Various methods of active thermography like Lock-In Thermography and Pulse Phase Thermography are imaging procedures that perfectly suit for contact-free and non-destructive material testing. In connection with high-resolution infrared cameras, they allow for quick detection of material defects and open up new possibilities in research, development and quality assurance.

Modular Automated Test Bench

- Thermal analysis of electronic and semiconductor devices

- Modular test bench for online lock-in measurement

- Reliable detection of thermal anomalies in the mK and μK range

- Spatial location of defects in multilayer PCBs and multi-chip modules

- Use of thermographic systems with cooled and uncooled detectors

- Operational software IRBIS® 3 active with comprehensive analysis options in laboratory conditions

Automated Testing Solution E-LIT

Electronics & Electrical Engineering

Learn more about thermography in electronics & electrical engineering

E-LIT – Lock-In Thermography for Electronics is an automated testing solution system (as part of NDT techniques) which allows non-contact (electrical) failure analysis of semiconductor material during the manufacturing process. Inhomogeneous temperature distribution, local power loss, leakage currents, resistive vias, cold joints, latch-up effects and soldering issues can be measured with Lock-in Thermography. This is achieved by using the shortest measurement times combined with a high-performance thermographic camera and a specialised lock-in procedure.

The power supply for this process is clocked with a synchronization module and failures that produce mK or even μK temperature differences are reliably detected by the lock-in thermography system.

Smallest defects at electronic components like point and line shunts, issues from overheating, internal (ohmic) shorts, oxide defects, transistor and diode failures on a PCB surface, in integrated circuits (IC´s), LED modules and battery cells can be detected and displayed in x and y positions. Additionally, it is possible to analyse stacked-die packages or multi-chip modules in z-direction with merely changing the lock-in frequency.

The powerful lock-in thermography software uses the latest algorithms and routines from most recent scientific publications.

E-LIT is extremely powerful also in resolving smallest geometrical structures as it can be equipped with strong microscopic lenses and additional SIL lenses. Identifying smallest structures with InfraTec´s E-LIT does not mean that the resulting field of view will also be smallest – implementing thermal cameras with detector sizes of up to (1,920 x 1,536) pixels provide large scale microscopic imaging. For even larger imaging stitching options are available.

Benefits of the Modular Test Bench

- Online lock-in measurement with the highest sensitivity

- Complete and detailed microscopy analysis

- Geometrical resolution up to 1.3 μm per pixel with microscope lenses

- Thermal resolution in the microkelvin range

- Multi-layer analysis

- Automatic scanning of larger samples due to precision mechanics

IC and Semiconductor Testing by Lock-in Thermography Automation from InfraTec

Get an impression about the construction and function of this automated testing solution system as well as the opportunities of the thermographic software IRBIS 3. E-LIT is used for non-contact failure inspection of electronics.

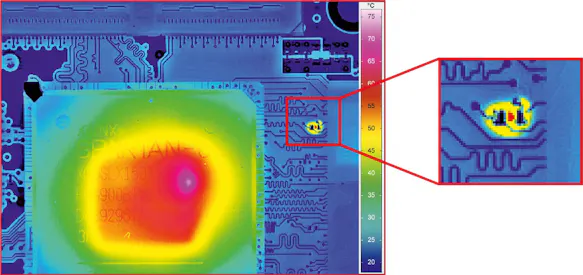

Thermographic Images with Different Optics

100 mm telephoto lens with 500 mm close-up; pixel resolution 75 μm

1x microscopic lens; pixel resolution 15 μm

3x microscopic lens; pixel resolution 5 μm

Thermographic Software IRBIS® 3 active

- Operational software with comprehensive analysis options in laboratory conditions

- Software add-on for automatic error classification based on parameter settings

- Intuitive user interface for easy operation

- Real-time display of the object being measured in various states

- Multifaceted memory options for image data and measurement results

- Alternative 0°, 90° or customised set phase angle image for representation of complex intensity information

- Merging live and amplitude image

- Optional: IV measurement, under sampling, drift compensation, DC-mode, power loss measurement, user and protocol administration, interface preparation: e.g. Profibus, Ethernet

Any questions?

Please contact our Technical Sales Engineer, Dr. Luke Nicholls, by email or on (01372) 337782.