InfraTec offers you exactly the system solution that meets your requirements. Starting with a single high-end infrared camera including thermography software up to the delivery of a complex, customised thermographic automation solution, you will receive the right product for your application.

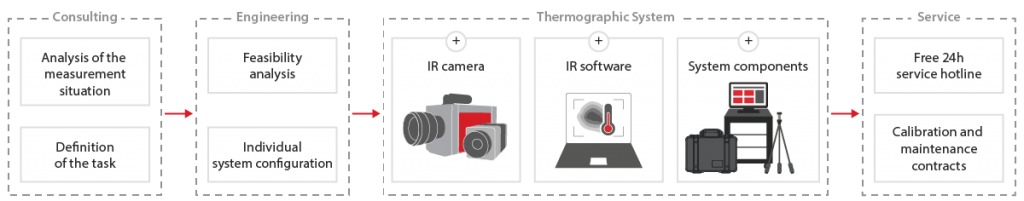

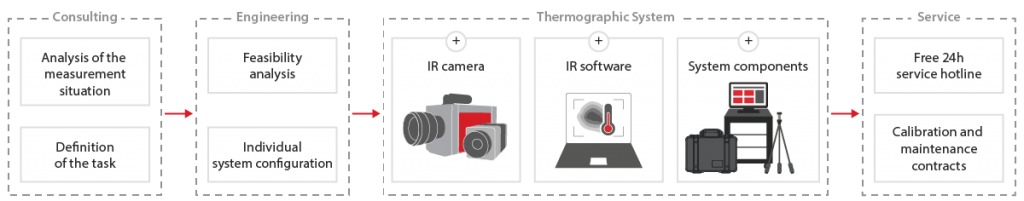

With these system solutions you receive the following services from InfraTec:

Thermographic Automation Solutions

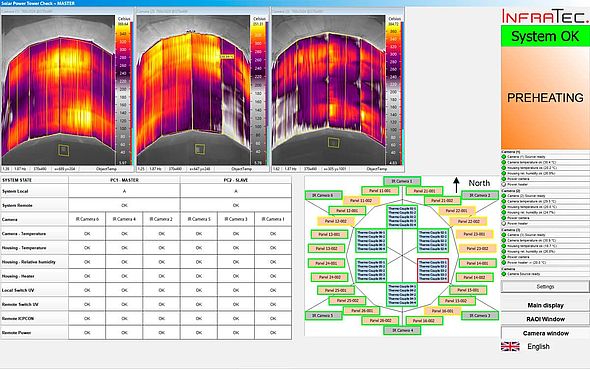

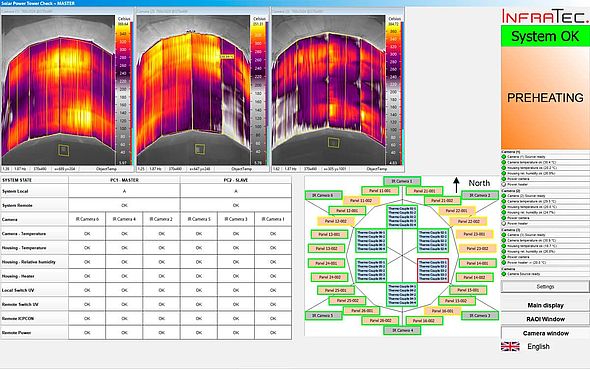

Automated thermographic solutions from InfraTec are based on our proven modular system. We configure a whole automated system for you that is tailored to your specific requirements. All components such as thermographic cameras, transmission and display devices, industrial PC and software are suitable for continuous industrial operation. You can use ATEX-certified protective housings and pan/tilt heads wherever the ambient conditions require it. Our system solutions provide you with reliable information about even the smallest temperature developments and distributions – efficiently and cost-effectively.

Infrared Cameras

We offer a comprehensive range of more than 30 infrared camera models. Our product range comprises entry-level devices, professional and universal cameras, high-end solutions as well as industrial thermal cameras and infrared imager. The range includes the high-end camera series ImageIR®, which is developed and manufactured at the headquarters in Dresden. For fixed installation, e.g. in harsh industrial environments, as well as for mobile use, the powerful uncooled thermographic systems VarioCAM® High Definition are suitable.

Automation Software for 24/7 Applications

This software kit is specially designed for thermography automation solutions from InfraTec. Offering extensive analysis and configuration options, the software can be precisely adapted to the individual requirements of measurement and testing situations and integrated into existing system environments.

InfraTec Service – Technical Support

Our Company’s own service department accompanies you even with complex automation solutions far beyond the actual sale. In the event of malfunctions, your enquiry is forwarded directly to the employees via a hotline. By remote maintenance, you will receive an initial diagnosis. Together with you, we analyse the cause of the problem and quickly find a solution.

Infrared Cameras for Integrators

Due to their modular concept, InfraTec infrared cameras can be flexibly customised to a wide range of industrial applications. Variable interfaces and a powerful SDK ensure fast integration into existing system environments. Our solutions are available on a long-term basis and are supplemented by excellent support.

Thermographic Software

The IRBIS® 3 software family provides a wide range of special software for convenient camera control and analysis of thermographic images. You can choose from a variety of packages and modules to analyse thermographic measurement data and comfortably generate thermographic reports. The range includes, for example, the stand-alone thermography report software IRBIS® 3 report and IRBIS® 3 active, a tool for thermographic inspection using active thermography.

Thermographic Automation Solutions at a Glance

Regardless of how diverse your task is, a thermography automation solution from InfraTec allows you to master the challenge efficiently and cost-effectively. Our proven modular system, consisting of a thermographic camera, transmission, display, interface, industrial PC and software components allows flexible adaptation to your specific requirements.

The core of the turnkey thermography automation solutions are our innovative, robust thermal imaging cameras with detector formats up to (1,920 × 1,536) IR pixels and frame rates into the kilohertz range. In conjunction with our modular hardware and software system, you receive tailored solutions for virtually all fields of industry and research.

Automated thermography solutions from InfraTec provide you with reliable knowledge about even the smallest temperature developments and distributions. Over 30 years of thermal imaging experience and more than 6,000 satisfied customers confirm our competence in this field.

Industrial Automation

With contactless temperature measurement you monitor temperature-critical processes efficiently and safely and control the quality of your products automatically.

Non-Destructive Testing (NDT)

In future, you will detect defects in materials and material combinations quickly and reliably by means of heat flow thermography.

Steel Production and Steel Processing

Thanks to state-of-the-art thermographic cameras you minimise production losses during production of high-grade steel even under adverse operating conditions.

Observation and Investigation

Monitor buildings and open spaces with automated thermography solutions, for example, against unauthorised intrusion or for early fire detection.

Your Benefits at a Glance

- InfraTec systems have proved effective in practice, are robust and have been designed for continuous industrial operation.

- Professional thermographic technology from Germany guarantees you maximum system availability.

- You can choose from a range of very compact microbolometer cameras up to cooled high-end cameras with focal plane array photon detectors featuring highest detectivity of (320 × 240) to (1,920 × 1,536) IR pixels and a frame rate of up to 25,000 Hz.

- The modular system design offers variability at the highest level and at a good cost-performance ratio.

- Your specific requirements determine the subsequent implementation.

- Extensive feasibility studies guarantee the lasting success of your investment.

- Modern interface concepts enable reliable camera control, data acquisition and online data evaluation even over extremely long distances.

- Experienced project engineers support you with the professional installation and commissioning at your premises.

Case Studies

WASTE-SCAN Against “Black Clouds”

WASTE-SCAN Monitoring System for Safety in Plant Operation

Early Fire Detection in Incineration Plant

Infrared Thermography Increases Safety in Waste to Energy Plant

Do you have any questions about your application?

Get in touch with our Technical Sales Manager, Dr. Luke Nicholls by email or call (01372) 378822.