Using AFM and Energy Dispersive Spectroscopy (EDS)

By combining the complementary strengths of SEM and AFM, FusionScope opens the door to a whole world of new application possibilities.

Modes: SEM, AFM Topography, EDS

Sample: Interlayer VIA Circuit

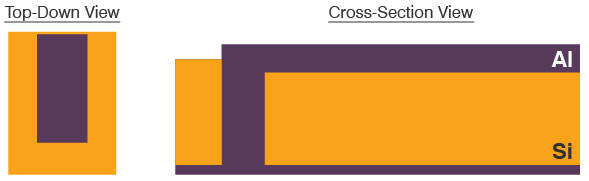

Failure analysis and quality control procedures are very important for determining errors in the manufacturing process and increasing yields of manufactured devices. This can be especially challenging in interlayer circuits, such as a VIA (Vertical Interconnect Access) circuit (Figure 1). In these cases, a three-part analysis using the correlated capabilities of SEM, AFM and EDS in the FusionScope can greatly increase knowledge about samples and help in their improved manufacturing.

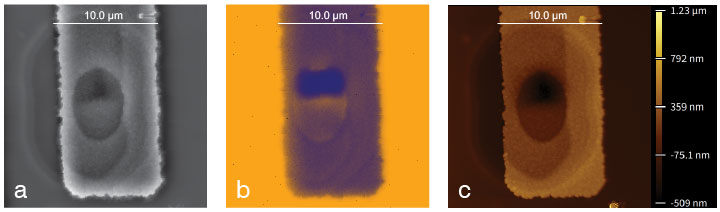

First, the SEM is used to map the large area and identify potential spots of failure by providing detailed imaging of the overlay error that occurs when layers of material are misaligned, decreasing the contact area and potentially lowering the device performance or in some cases leading to failure. The SEM image also provides high-resolution lateral information on the X and Y axes, facilitating the precise measurement of overlay accuracy (Figure 2a).

FusionScope’s unified coordinate system, along with the coordinates provided by the SEM, allow AFM measurements to be easily gained by executing an automated scan command. The complementary vertical surface information provided by the AFM data reveals the topographic details of the surface along the Z axis, which are not clear in the SEM image. In this example, the AFM reveals that the circuit line is thinned over the VIA, potentially contributing to an impaired electrical connection (Figure 2c).

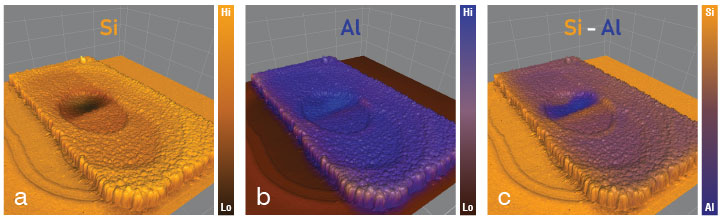

The SEM (Figure 2a) and AFM (Figure 2c) images show an oval region in the center of the line, which might lead to the conclusion that the VIA covers this entire area, ensuring a proper electrical connection. However, the elemental information acquired by the EDS image (Figure 2b) reveals a higher concentration of aluminum (Al) at the upper central part of the oval feature, surrounded by silicon (Si). This indicates that the VIA is not centered and is smaller than the oval feature observed in the SEM and AFM images. By combining this with the topographic information from AFM (Figure 3) we can determine that the VIA only contacts the top Al line, where the line is thinned, indicating an even weaker electronic connection.

It would not be possible to fully understand the details of this failure without the correlated information from SEM, AFM, and EDS. This correlative approach allows for more precise identification and characterisation of defects, improving diagnostic accuracy. This way, the weaknesses in the design and production process can be better identified. The ability to analyse failures rapidly and accurately can reduce downtime and costs associated with troubleshooting and repairs, ultimately enhancing the reliability and performance of electronic devices.

Easy to use Correlative AFM with SEM Microscopy Platform

FusionScope is an easy-to-use correlative microscopy platform designed from the ground up to add the benefits of SEM imaging to a wide range of AFM measurement techniques.

Contact Us

Get in touch with our Sales Manager, Dr. Luke Nicholls, to discuss your failure analysis challenges and how the FusionScope might solve them. Email Luke below or call (01372) 378822.