- Features

- Models

- Specifications

- Videos

- Applications

- Related Products

- Contact

- Back To Spectroscopy

- Back To Optics

- Back To Hyperspectral

- Back To Cameras

- Back To X-Ray

- Back To Light Measurement

- Back To Characterisation

- Back To Electron Microscopy

- Back To Magnetometry

- Back To Ellipsometers

- Back To Cryogenics

- Back To Lake Shore

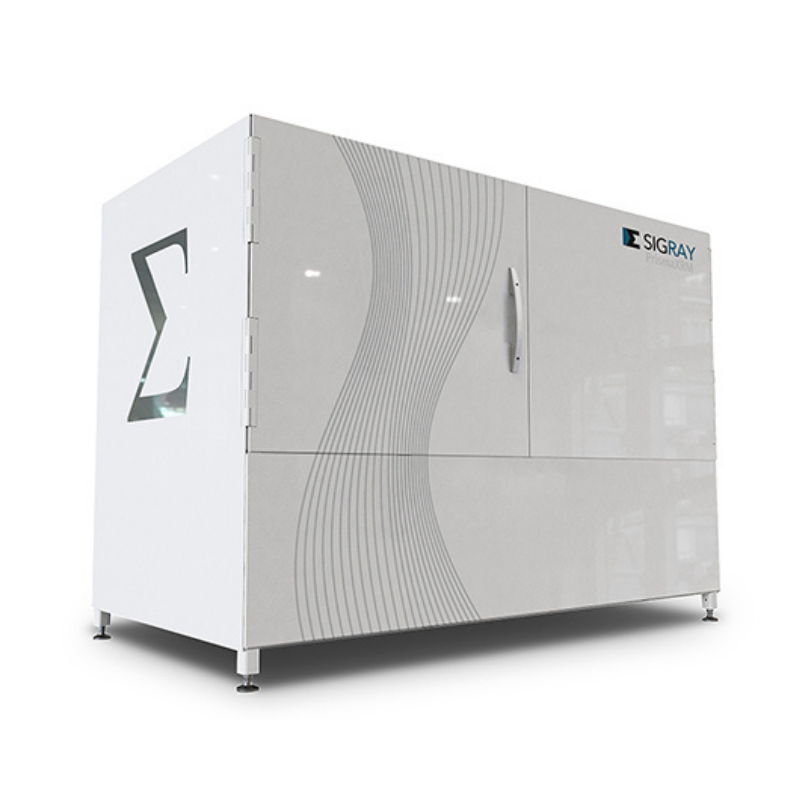

Sigray PrismaXRM Tri-Contrast X-Ray Microscope

AWARD-WINNING SUB-MICRON 3D X-RAY MICROSCOPE

Novel Tri-Contrast Capabilities

Spatial resolution 0.5 µm

Designed for in-situ Experiments

Introducing PrismaXRM: the 3D X-ray microscope with the resolution and performance of the industry leaders… and more. The world’s most advanced tri-contrast imaging system, PrismaXRM represents the next generation of laboratory micro-CT.

FEATURES

- 3D x-ray microscope with industry-leading spatial resolution

- Achieve down to 0.5 µm spatial resolution and <100nm voxels

- Maximum versatility with novel contrast mechanisms

- Patented multi-spectral source (MSS) for quasi-monochromatic illumination to allow up to 10X throughput on the most difficult-to-image, low contrast samples

- Multiple detectors in a single system

- Optimise your field of view and resolution

-

Nanofocus X-ray source and optional second source

- Software: GigaRecon Tomography and Sigray3D Acquisition

HIGHLIGHTS

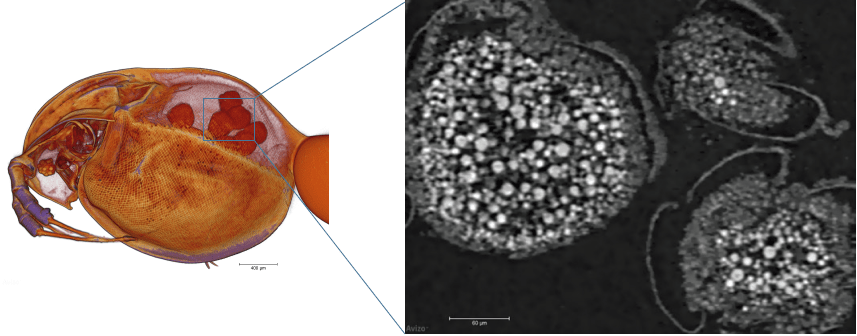

PrismaXRM achieves the highest spatial resolution available on the market at 500nm (0.5 µm).

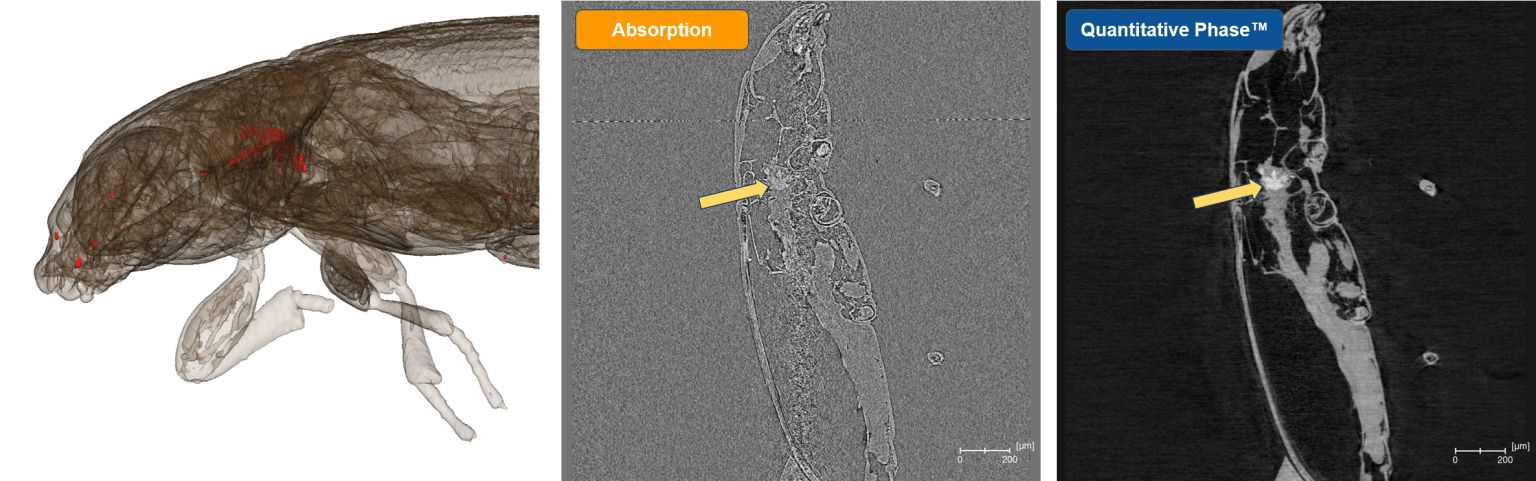

Shown below are individual eggs resolved in the eggs sacks of a daphnia (water flea) specimen.

PrismaXRM was engineered to address the needs of busy central research facilities, which encounter a wide variety of sample shapes, sizes, and composition. The research facilities are often tasked with imaging the samples at the best quality and at the fastest acquisition times. Because no single set of components can address the full range, PrismaXRM can incorporate multiple x-ray sources and detectors into a single system. One key option is a Multi-Spectral Source (MSS) that is also used in Sigray’s ChromaXRM system. This source provides multiple quasi-monochromatic beams of x-rays (unlike the polychromatic x-rays produced by most system’s sources) to provide the outstanding contrast needed for extremely challenging samples, such as low-Z structures in novel lithium battery concepts and biological samples.

Image: PrismaXRM-800 can incorporate the patented Multi-Spectral Source used in the Sigray ChromaXRM-500, which provides outstanding contrast for challenging samples because it produces quasi-monochromatic x-rays.

PrismaXRM offers both Quantitative Phase and propagation phase contrast capabilities. Unlike propagation phase contrast, which is an edge-enhancing technique, Quantitative Phase provides direct access to the refractive index of a material, allowing decoupling of the material’s atomic number (Z) from its density. This complements absorption contrast which is a convolution of Z and density. Quantitative Phase also provides excellent performance for biological materials and polymers – and is particularly sensitive to voids and cracks.

Image: Quantitative Phase allows phase retrieval, providing clear separation of electron density.

SPECIFICATIONS

| Parameter | Specification | |

|---|---|---|

| Overall | Spatial Resolution | 0.5 um with 40X objective |

| Source | Type(s) | Sealed tube(s) Nanofocus standard Optional second transmission or reflection source |

| Voltage | 30 – 160 kVp | |

| Target(s) | Up to 5 targets. Includes selection from Cr, Cu, Rh, W, Mo, Au, Ti, Ag. Others available upon request. |

|

| Detector(s) | Type | Up to 5 detectors. Includes LFOV detectors and high resolution detectors. |

| Camera | 4MP deep cooled CCD | |

| Visible Light Camera | 16MP alignment camera | |

| Software | Command and Control | Sigray 3D with Intuitive interface |

| Reconstruction | GigaRecon – fastest commercial CBCT reconstruction software | |

| Offset Scans | Expands the horizontal FOV. Sigray software advantage | |

| Helical Scan | Enabled for tall samples | |

| AutoPilot | AI-assisted microscope operation for unsupervised acquisition | |

| Linux Workstation | Interface is on a Windows workstation, while a separate robust Linux workstation controls the system. Advantageous for reliable 24-7 operation. | |

| EPICS | Open-source software controls for maximum flexibility | |

| Dimensions | Footprint | 88″ L x 49″ W x 92″ H |

| Maximum Sample Size | 30cm width and 50cm height* *Note max FOV is limited by each detector |