Thermographic NDE

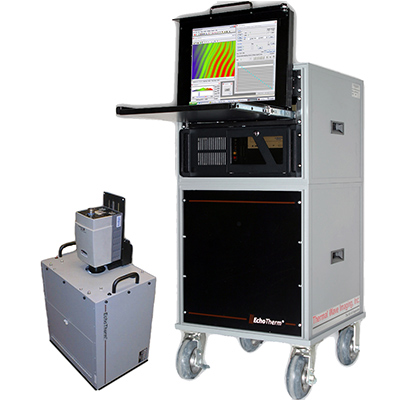

EchoTherm from Thermal Wave Imaging

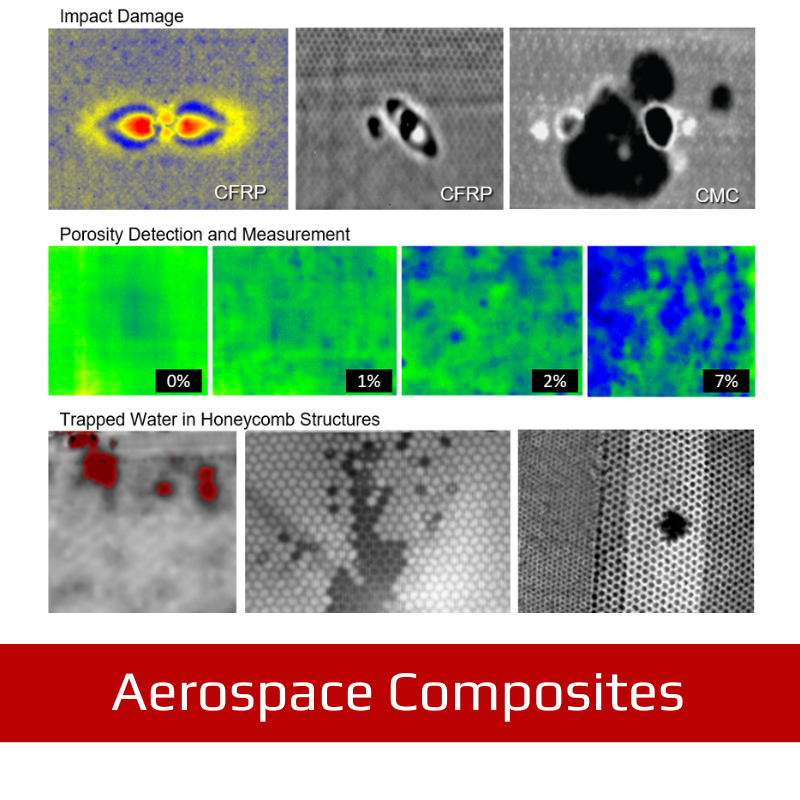

EchoTherm® is the system of choice for any tough non-destructive evaluation (NDE) application – from automated manufacturing to aircraft inspection. The system provides fast, non-contact, wide area inspection of flat or curved structures, and can measure depth and area of subsurface defects. Since its introduction in 1992, EchoTherm has been the benchmark system for thermographic NDE.

The EchoTherm Advantage

EchoTherm defines state of the art in IR NDT for manufacturing, R&D and automated inspection applications. Achieve high quality, repeatable test results quickly and cost effectively. EchoTherm gives you the following benefits:

- Fast

- Accurate

- Quantitative

- Cost effective

- Safe

- Non-contact

- Single-side process

- Easily interpreted

- Wide area

FEATURES:

- Quantitative measurement

- Open architecture

- Advanced analysis and processing routines

- Compatible with leading IR cameras

- Configurable for use in factory, field or lab