Magnetic Products Brochure

Welcome to your essential guide to Lake Shore Cryotronics Magnetic Products, presented by Quantum Design UK & Ireland. This brochure brings together the full suite of magnetic field measurement instrumentation—including gaussmeters, Hall probes and sensors, fluxmeters, and Helmholtz coils—into one convenient reference.

Lake Shore’s magnetic products are trusted across research labs, manufacturing, and industrial testing environments to capture accurate data on field strength, shape, fringe effects, and uniformity. Whether you need to sort magnet assemblies, map field profiles, or diagnose performance issues, a Lake Shore gaussmeter—with Hall probes or a fluxmeter—is often the instrument of choice.

This brochure highlights:

-

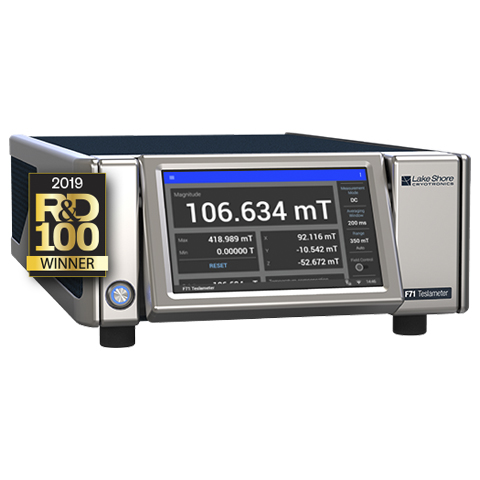

Gaussmeters and Teslameters: Precise measurement of field intensity at specific points or across gaps.

-

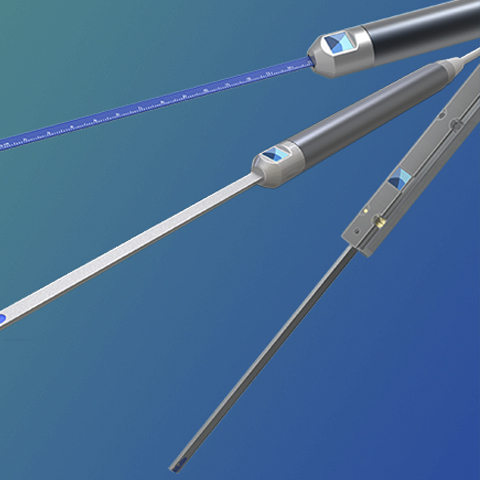

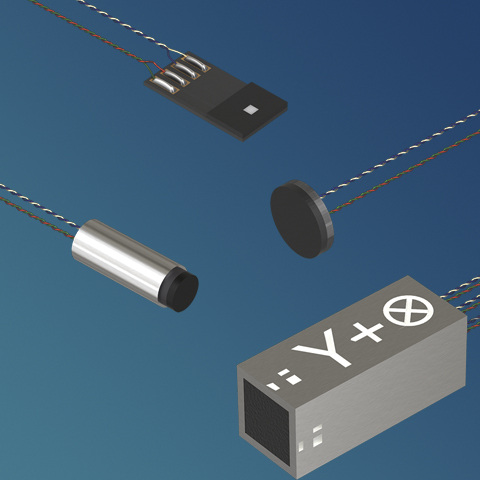

Hall probes and magnetic sensors: Axial, transverse, multi-axis and cryogenic versions available—with a range of geometries and sensitivities.

-

Model 480 Fluxmeter: Ideal for total flux and hysteresis loop measurement, magnet sorting, and quality control applications─compatible with sensing coils and fixtures used in automated setups QD UK.

-

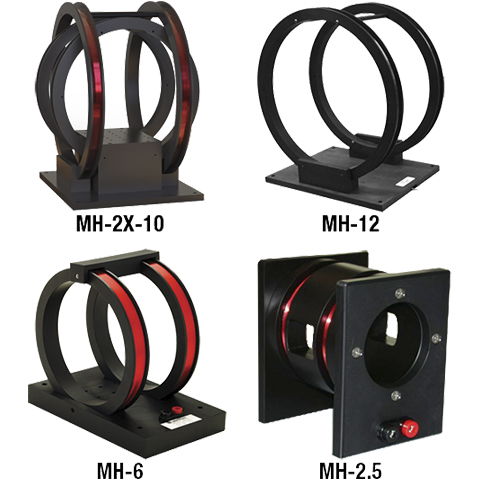

Helmholtz and search coils: For uniform field generation and calibration or field mapping tasks.