High-Tech Instrumentation for the Aerospace Industry

In today’s rapidly advancing aerospace sector, precision and performance are not just desired—they’re essential.

From spacecraft engineering to defence systems and airborne platforms, the industry demands cutting-edge tools capable of withstanding extreme conditions while delivering unmatched reliability. In this latest edition of our aerospace magazine, Quantum Design UK and Ireland (QDUKI) showcases the high-tech instrumentation driving innovation across the entire aerospace spectrum.

Engineers, scientists, and defence professionals rely on our advanced technologies to solve complex challenges, whether they’re developing next-generation spacecraft or maintaining mission-critical defence systems. Among the highlights featured in this issue are powerful systems for sub-PPM contaminant detection in quartz windows—a critical capability for spacecraft optics—and advanced non-destructive testing (NDT) tools that detect microscopic flaws in solder joints before they compromise performance.

This issue is not just about technology—it’s about partnership. The instrumentation we provide is enhanced by the expertise and innovation of our trusted collaborators, whose contributions are helping to shape the future of aerospace. Our experienced sales team works closely with customers to identify needs and deliver tailored solutions that align perfectly with application requirements.

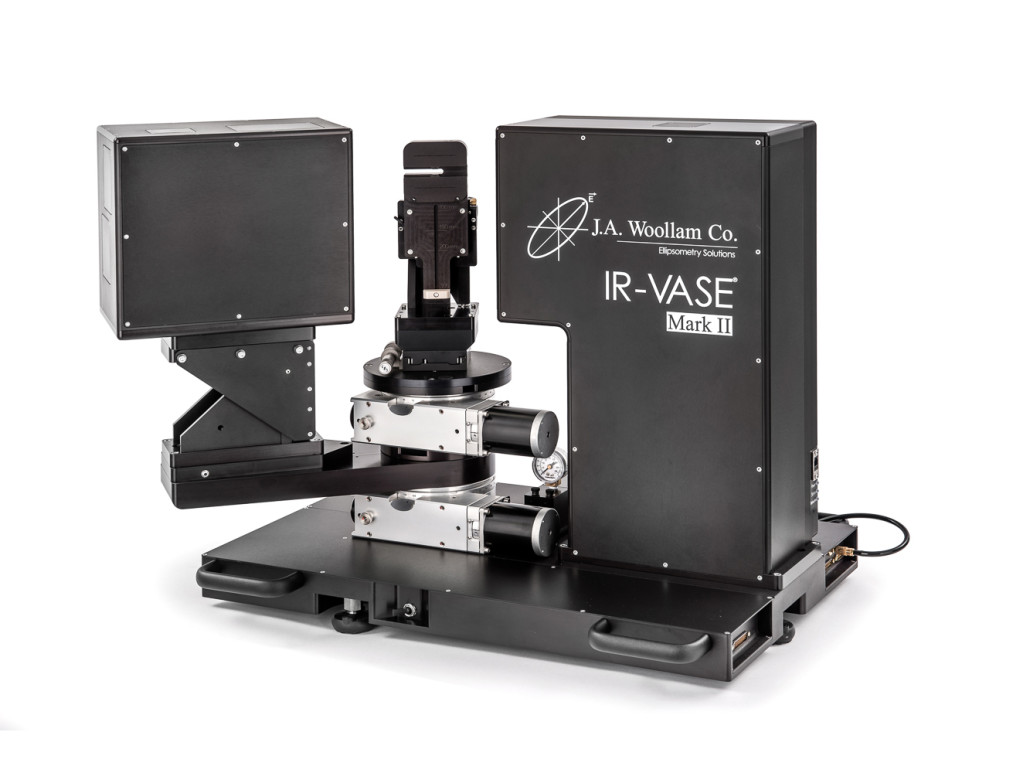

For Stealth Coatings Applications

The IR-VASE II allows engineers to precisely measure the complex refractive index (n and k values) across a broad IR range, enabling optimisation of materials to meet these stealth requirements. For example, by understanding the spectral absorption behaviour of a coating, one can fine-tune it to suppress reflection in specific IR bands used by thermal imaging systems.

J.A. Woollam IR-VASE II Ellipsometer

AEROSPACE HERITAGE OF LAKE SHORE CRYOTRONICS

Since integrating Janis Research into its product line in 2020, Lake Shore Cryotronics has manufactured numerous custom-designed cryogenic systems specifically suited for aerospace and astronomy applications. With decades of experience delivering rugged, mission-ready equipment, Lake Shore—through its Environment by Janis division—offers cryostats engineered to meet the extremes of space and high-altitude environments.

Custom cryogenic systems from Janis have been deployed in collaborations with NASA and other leading institutions:

- The ARC Argus program (successor to ATLAS), enabling high-altitude atmospheric research using stable tracer detection.

- Qualification test hardware for the SIRTF (now Spitzer Space Telescope), operating at liquid-helium temperatures under mirror test protocols—a project that earned Janis a Public Service Group Achievement Award from JPL.

- A terrain simulation chamber for Mars environment testing, built with NASA GSFC and UMD, replicating extreme cold and dust conditions.