- Features

- Models

- Specifications

- Applications

- Related Products

- Contact

- Back To Spectroscopy

- Back To Optics

- Back To Hyperspectral

- Back To Cameras

- Back To X-Ray

- Back To Light Measurement

- Back To Characterisation

- Back To Electron Microscopy

- Back To Magnetometry

- Back To Ellipsometers

- Back To Cryogenics

- Back To Lake Shore

Sigray Apex XCT-100 3D X-Ray Microscope

Rethink Impossible | Sub-Micron 3D X-ray In Minutes

Introducing the Apex XCT-100 system. This special 3D X-ray Microscope is designed specifically to analyse large wafer samples, up to 300 mm, and for use in advanced semiconductor packaging and failure analysis.

FEATURES

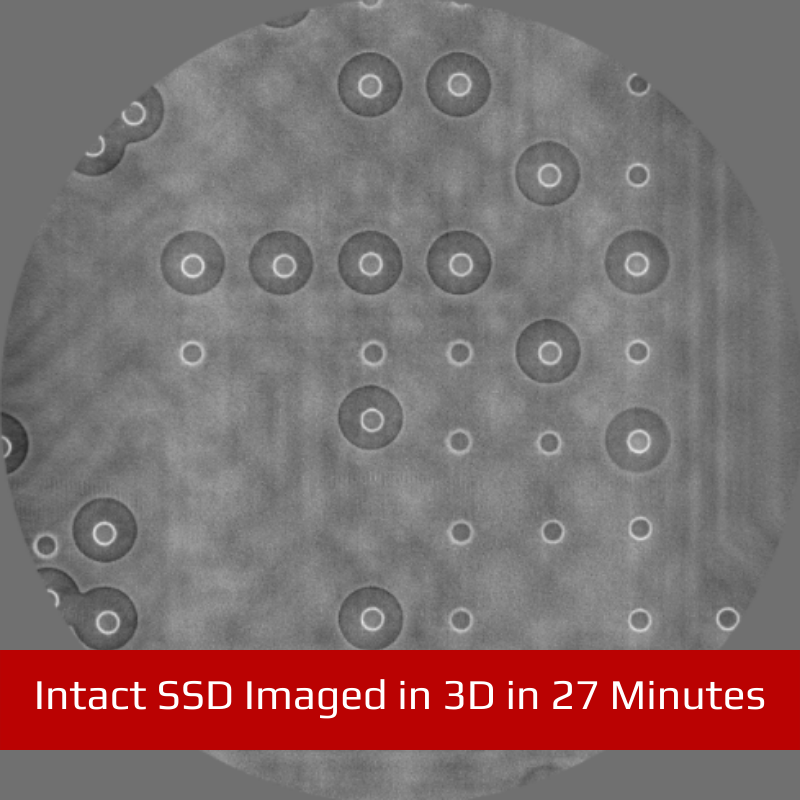

- 3D Imaging on Intact Samples Up to 300 mm Diameter

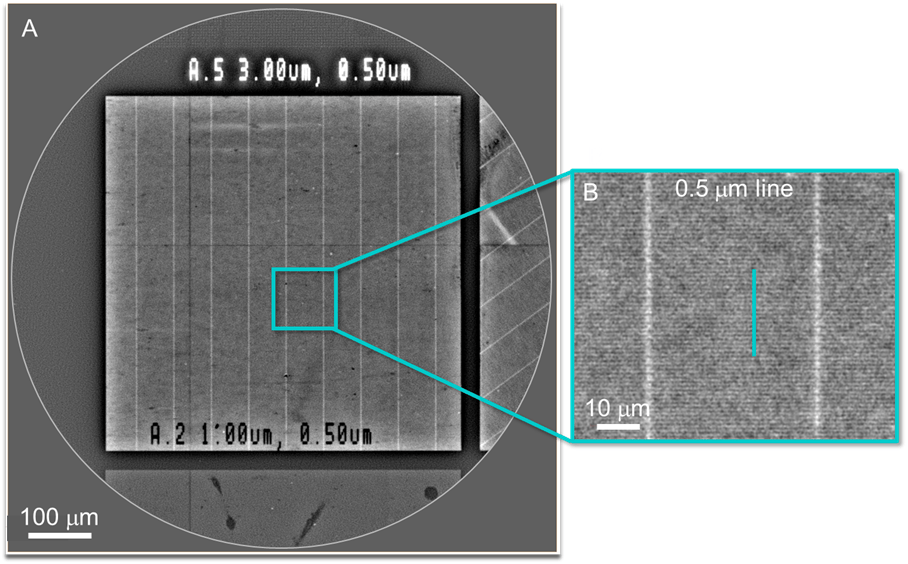

- 0.5 µm 3D Spatial Resolution in < 15 Minutes

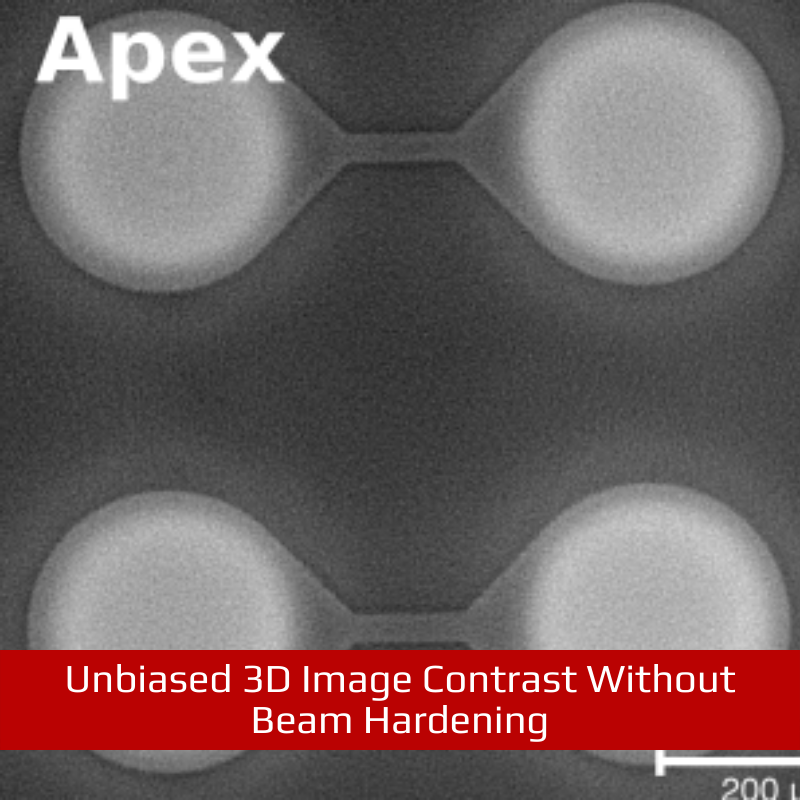

- No Beam Hardening Artifacts

- 0.5 Micron with Unlimited Sample Size

- Isochronous Data Acquisition

- Unbiased Contrast

HIGHLIGHTS

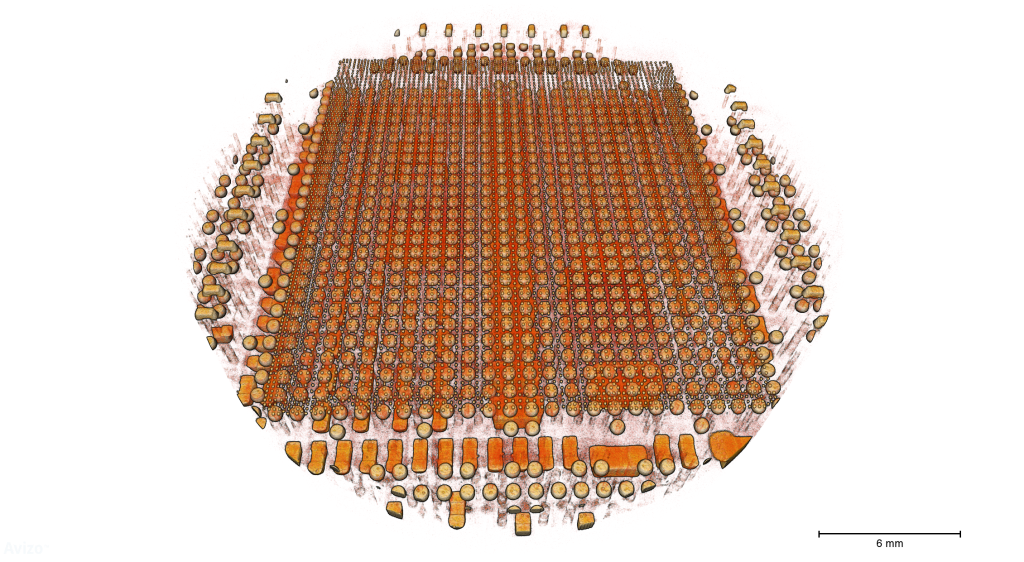

Image with 0.5 micron spatial resolution anywhere on samples up to 300 mm in diameter. With Apex XCT, you can streamline your FA workflows by imaging whole intact packages, wafers, and PCBs, mitigating time-consuming and destructive sample preparation protocols.

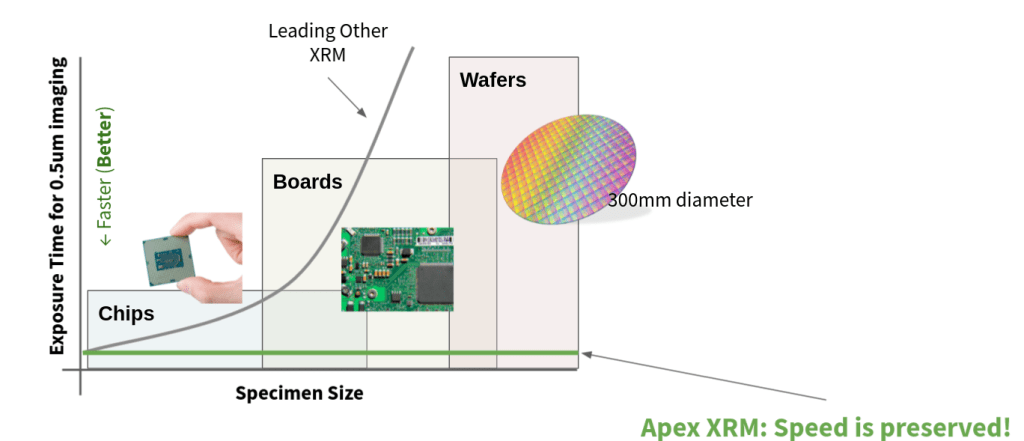

Data acquisition time is independent of sample size when using Apex XCT. Unlike legacy CT systems where bigger samples equate to longer measurement times, the unique geometry of Apex XCT preserves high throughput operation even as sample sizes grow very large, such as printed circuit boards, motherboards, and wafers.

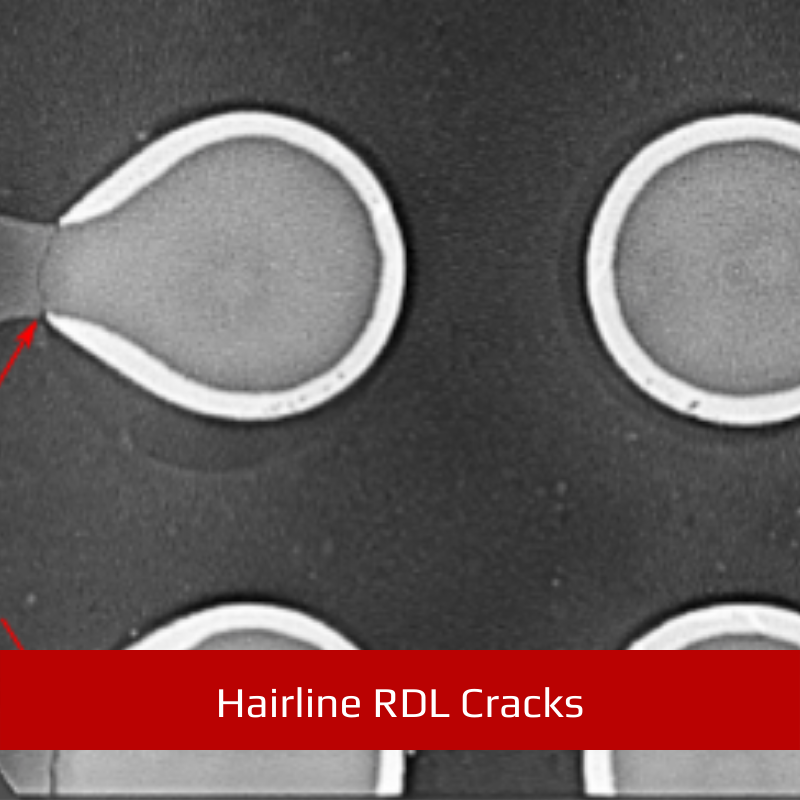

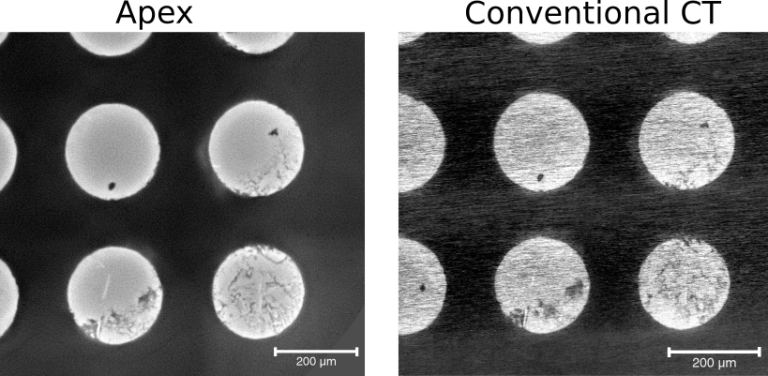

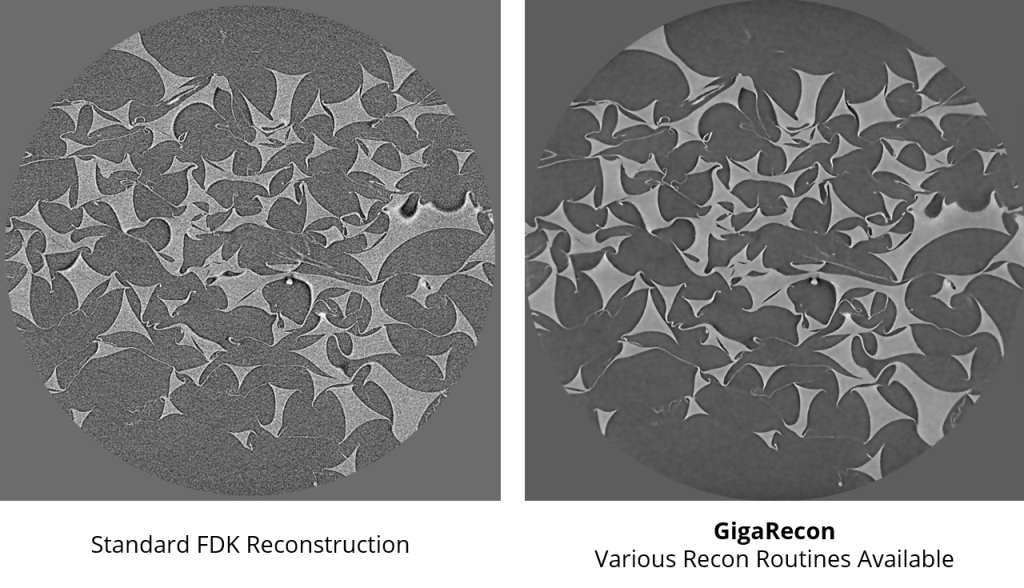

Apex XCT eliminates many of the imaging artifacts that affect operation of conventional 3D X-ray systems, such as beam hardening, streaking/curtaining, photon starvation, and metal artifacts. Compare the same region imaged with Apex XCT (Left) and a leading Conventional XRM/microCT (Right) – the Apex XCT result demonstrates a dramatic increase in image quality while also offering a significantly reduced scan time.

A state-of-the-art 25-watt 30-160 kVp nanofocus sealed tube X-ray source combines highest power and spatial resolution with maintenance-free operation.

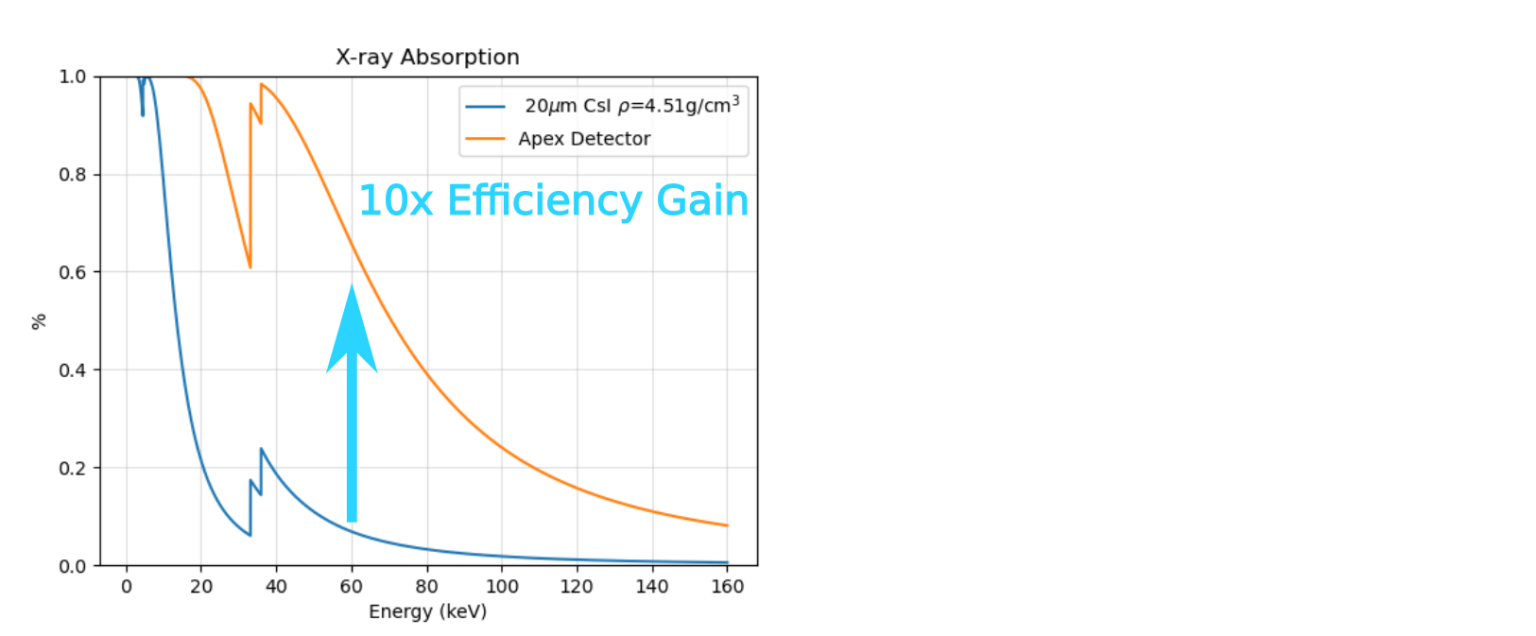

The detection system of Apex XCT has been carefully optimized for high-resolution, high-throughput operation at voltages up to 160 kV. Legacy CT systems rely on thin scintillators for high-magnification imaging, which are highly inefficient at high energies. Apex XCT, by comparison, absorbs a much wider portion of the X-ray spectrum offering drastic throughput improvements.

GigaRecon | Tomographic reconstruction software that pairs the fastest reconstruction times with an unmatched suite of features for achieving the best result every time. Reconstruction speeds of <45 seconds are achieved for 2048 x 2048 x 2200 datasets. GiagRecon provides the fastest iterative tomography reconstruction on the market, enabling high quality image reconstruction with 5X shorter data collection time, substantially accelerating tomography imaging time over conventional FDK reconstruction.

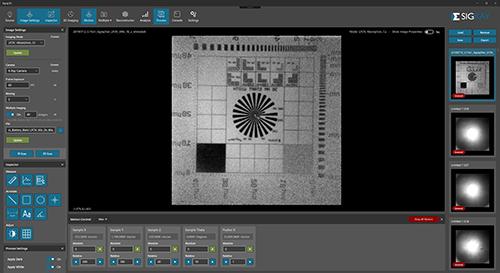

Sigray3D | Intuitive Acquisition

- Easy, intuitive software gets your team up and running in no time

- Click to align the sample and start measuring in seconds

- AI powered AutoPilot suggests the optimal settings for each sample

- Queue up to 20 samples with the automated Sample Handling Robot (SHR)

SPECIFICATIONS

| Parameter | Specification | |

|---|---|---|

| Overall | Spatial Resolution | 0.5 um |

| Minimum Voxel | 70 nm | |

| Source | Type | Nanofocus Sealed Tube Transmission X-ray Source |

| Voltage | 30 – 160 kVp | |

| Power | 25W | |

| Target(s) | Tungsten | |

| Detector(s) | Type | 6.7 MP 50 micron pixel size 9 FPS 14×11 cm (Upgrade) 26.9 MP 50 micron pixel 22 fps 28×24 cm |

| Visible Light Camera | 16MP alignment camera | |

| Software | Command and Control | Sigray 3D with Intuitive interface |

| Reconstruction | GigaRecon – fastest commercial CBCT reconstruction software | |

| Continuous (or Fly) Scan Data Acquisition | Standard | |

| Sample Handling Robot | Queue up to 20 samples without operator intervention | |

| Linux Workstation | Interface is on a Windows workstation, while a separate robust Linux workstation controls the system. Advantageous for reliable 24-7 operation. | |

| EPICS | Open-source software controls for maximum flexibility | |

| Dimensions | Footprint | 88″ L x 49″ W x 92″ H |

| Sample Size | 300 mm diameter x 25 mm height |