Epoxy

Epoxy Features

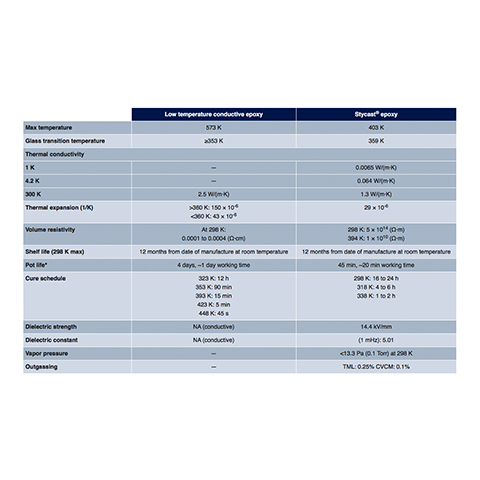

Epoxies are used to install and fasten sensors, while providing thermal contact and electrical insulation, with the sample. Epoxy can also be used for mechanical attachment and joints. Stycast® 2850FT is a black epoxy resin, and has a thermal expansion coefficient that is matched to copper. A silver-filled, low-temperature conducting epoxy provides excellent strength, along with electrical and thermal conductivity.

Epoxy Types

This epoxy is used to permanently attach test samples or temperature sensors to sample holders. It is a 100% solid, two component, low temperature curing, silver-filled epoxy which features very high electrical and thermal conductivity combined with excellent strength and adhesive properties.

| Part number | Description |

| ESF-2-5 | Low temperature conductive epoxy, 5 packets, 2 g each |

| ESF-2-10 | Low temperature conductive epoxy, 10 packets, 2 g each |

- Excellent low temperature thermal and electrical conductivity

- Low viscosity

- Thixotropic

- No resin bleed during curing

- Low weight loss

- Low volatility

Note: Epoxy must be cured at a minimum of 50 °C for 12 h to achieve proper electrical and physical properties. Curing at 175 °C for 45 s will achieve optimum properties.

ESF-2-5 and ESF-2-10 can be used to 300 mK and below. Results may vary based on application and materials used.

Stycast® is the most commonly used, highly versatile, nonconductive epoxy resin system for cryogenic use. The primary use for Stycast® is for vacuum feedthroughs or permanent thermal anchors. Lake Shore uses this product in vacuum tight lead-throughs with excellent thermal cycle reliability. Stycast® is an alternative to Apiezon® N grease when permanent sensor mounting is desired. (Can place stress on sensor — more information.)

| Part number | Description |

| ES-2-20 | Stycast® epoxy, 20 packets, 2 g each |

We are not able to accept returns of this product.

- Mixed and applied from two-part flexible packets

- Excellent low temperature properties

- Permanent mounting

- Exceptional electrical grade insulation properties

- Low cure shrinkage

- Low thermal expansion

- Resistance to chemicals and solvents

Note: Can be chemically removed with methylene-chloride (several hour soak).