- Features

- Models

- Options

- Videos

- Downloads

- Related Products

- Contact

- Back To Spectroscopy

- Back To Optics

- Back To Hyperspectral

- Back To Cameras

- Back To X-Ray

- Back To Light Measurement

- Back To Characterisation

- Back To Electron Microscopy

- Back To Magnetometry

- Back To Ellipsometers

- Back To Cryogenics

- Back To Lake Shore

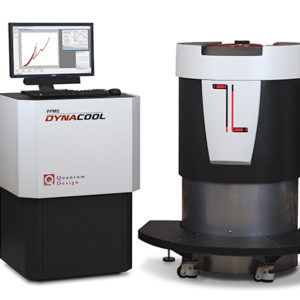

Quantum Design ATL Helium Liquefiers

Automated 160 Litre Capacity Helium Liquefiers

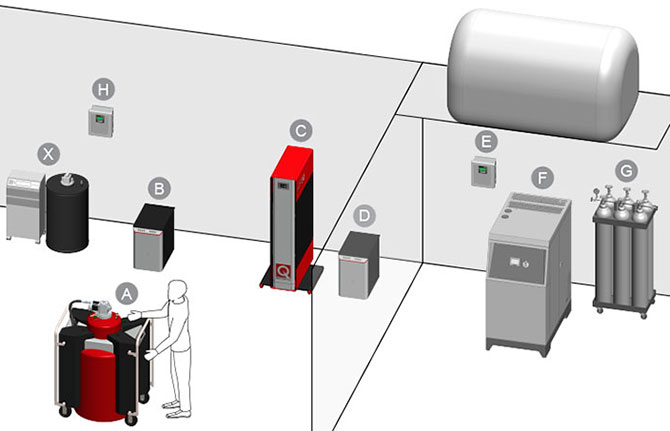

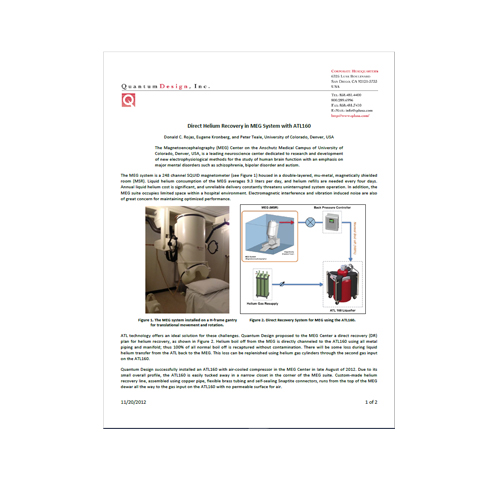

Quantum Design’s Advanced Technology Liquefiers (ATL) and innovative Helium Recovery, Storage & Purification Systems allow you to recover and liquefy the helium gas currently being lost from the normal boil off and helium transfers of your cryogenic instruments. A perfect solution for research or medical cryostats, Quantum Design’s helium liquefiers and recovery systems allow you to break your dependence on suppliers and no longer be subject to higher costs and diminished supply.

FEATURES

- Easy-to-use, fully automated operation

- Portable liquefiers for easy transfers

- High liquefaction rates up to 30+ litres per day

- Self-cleaning, uninterrupted service

- Modular design: your system can grow as your Helium needs evolve

- Versions available for Direct, Medium and High Pressure Recovery

MODELS

ATL160+ Specifications

- Average Liquefaction Rate: 30+ litres/day (1.25 litres/hr)*

- Dewar Capacity: 160 litres

- System Dimensions (L x W x H): 104 x 76 x 151 cm (liquefier without compressor)

- Compressor Package Model: Water-Cooled

- Typical Power Consumption and Voltage Range: 6.5 – 7.5 kW; High & Low Voltage Available

- Gaseous Helium Requirement:

Flow Rate: 0 – 25 SLPM (0 – 0.88 SCFM); Ultra High Purity He (99.999% pure); 1-23 PSIg - Fully Automated Touch Panel Control

* Liquefaction rates vary based on transfer frequency, input helium quality and pressure

ATL160 Specifications

- Average Liquefaction Rate: 22 – 27 litres/day (0.92 – 1.13 litres/hr)*

- Dewar Capacity: 160 litres

- System Dimensions (L x W x H): 104 x 76 x 151 cm (liquefier without compressor)

- Compressor Package Model: Split Air-Cooled or Water-Cooled

- Typical Power Consumption and Voltage Range: 6.5 – 7.5 kW; High & Low Voltage Available

- Gaseous Helium Requirement:

Flow Rate: 0 – 25 SLPM (0 – 0.88 SCFM); Ultra High Purity He (99.999%); 0-12 PSIg - Fully Automated Touch Panel Control

* Liquefaction rates vary based on transfer frequency, input helium quality and pressure