- Features

- Models

- Options

- Downloads

- Related Products

- Contact

- Back To Spectroscopy

- Back To Optics

- Back To Hyperspectral

- Back To Cameras

- Back To X-Ray

- Back To Light Measurement

- Back To Characterisation

- Back To Electron Microscopy

- Back To Magnetometry

- Back To Ellipsometers

- Back To Cryogenics

- Back To Lake Shore

Helium Liquefiers, Purifiers and Helium Recovery Systems

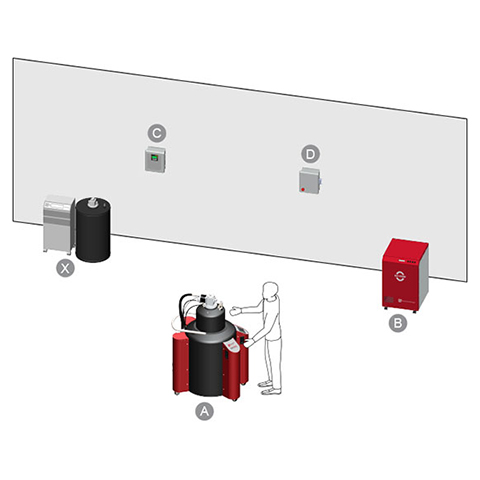

Quantum Design NexGen Liquefiers and ATP Purifier

Quantum Design’s full line of liquefiers and purifiers allow you to recover and liquefy the helium gas currently being lost from the normal boil off and helium transfers of your cryogenic instruments. A perfect helium recycling solution for research and medical cryostats, Quantum Design’s helium liquefiers and purifiers allow you to break your dependence on cryogen suppliers and no longer be subject to higher costs and undependable supply. You will also be doing your part to conserve a precious natural resource which is vital to scientific research and medical treatment.

Quantum Design liquefiers are mobile and easy to move around your laboratory, which makes the transfer of liquid helium more convenient than ever. Liquefiers are doorway- and ramp-friendly, and the transfer process is as easy as transferring from your current storage dewars. Our helium recycling technology is also modular so that systems can be designed for needs small or large and then expanded as needs grow.

* Consulting services for recovery plant design are available upon request.

What our customers are saying..

Physics Department, Leiden University

“The small liquefiers are easy to use and can deliver 500-600 litres per week to satisfy our institution’s needs.”

Servicios Científico-Técnicos, University of Oviedo

“We were most surprised by the high level of Helium recovery made possible by the ATL system.”

Read about these Case Studies

FEATURES

- Easy-to-Use, Fully Automated Operation

- Portable Liquefiers for Easy Transfers

- 250 Litre Capacity Allows Larger Transfers!

- High Liquefaction Rates; Energy Efficiency

- Liquefies at 1 PSIg so Helium is Ready When You Need It

- Self-Cleaning, Uninterrupted Service

- Software with Intuitive User Interface for Easier Operation

- Modular Design: Your System Can Grow as Your Helium Needs Evolve

LIQUEFIER AND PURIFIER MODELS

NEXGEN 160 SPECIFICATIONS

- Liquefaction Rate: 20+ liters/day (typical)*

- Dewar Capacity: 160 liters

- System Dimensions (L x W x H): 104 x 71 x 152 cm (liquefier without compressor)

- Compressor Package Model: Water-Cooled (variable speed optional)

- Power Consumption and Voltage Range: 6.5 – 7.5 kW (typical); High & Low Voltage Available

- Gaseous Helium Requirement: Ultra-High Purity (UHP) He (99.999%)

- Fully Automated Touch Panel Control

* Liquefaction rates vary based on transfer frequency, input helium quality and pressure. In countries where the power line frequency is 50 Hz, the liquefaction rate can be 20% lower (unless using the variable speed compressor).

NEXGEN 250 SPECIFICATIONS

- Liquefaction Rate: 25+ litres/day (typical)*

- Dewar Capacity: 250 litres

- System Dimensions (L x W x H): 114 x 81 x 160 cm (liquefier without compressor)

- Compressor Package Model: Water-Cooled (variable speed optional)

- Typical Power Consumption and Voltage Range: 6.5 – 7.5 kW; High & Low Voltage Available

- Gaseous Helium Requirement: Ultra-High Purity (UHP) He (99.999%)

- Perfect for NMR or other labs that prefer larger transfers less frequently!

- Fully Automated Touch Panel Control

* Liquefaction rates vary based on transfer frequency, input helium quality and pressure.

ATP30 PURIFIER SPECIFICATIONS

- Purifies 30 litres of helium gas per minute (typical)*

- Purifies helium gas to 99.9995% (better than UHP)

- Fail Safe Operation – Stops operation before “dirty” gas passes through system

- Full regeneration of system only takes 5 hours (with no filters or cartridges to replace)*

- Regeneration easily accomplished through automated software

- Ensures highest liquefaction rates possible

- Hydrogen removal option protects instruments from plugging

- System Dimensions (L x W x H): 60 x 69 x 148 cm (purifier without compressor)

- Compressor Package Model: Air-Cooled or Water-Cooled

- Typical Power Consumption and Voltage Range: 6.5 – 7.5 kW; High & Low Voltage Available

* Purifier operation varies based on input helium quality.