Home

About Us

Quantum Design UK and Ireland is one of the leading distributors of high-tech instrumentation and consumables for scientific, academic and industrial research.

Our dedicated team of sales and service engineers, are able to provide fast, flexible and reliable service to our customers.

We are part of the Quantum Design International (QDI) group. QDI manufacture and distribute scientific and industrial instrumentation through an international network with subsidiaries in every major technological

What our customers are saying about us

New Magazine

Quantum Design UK and Ireland (QDUKI) is excited to announce the latest magazine launch – “Cryogenics“, the second edition. Following on from our popular first edition, we have a jam-packed issue with new product launches, applications and case studies.

Free Magazines

- Space Magazine

- Cryogenics Magazine

- Imaging Cameras Magazine

- High-Tech Instrumentation Magazine

- Semiconductors Magazine

Rental Cameras

There are four different imaging cameras from InfraTec and Specim available to rent from QDUKI. Covering hyperspectral imaging and thermography.

You can now download hundreds of useful applications notes and documents for Quantum Design systems.

Upcoming Events

Bristol Quantum Information Technologies Workshop 2024

17th European Vacuum Conference (EVC17)

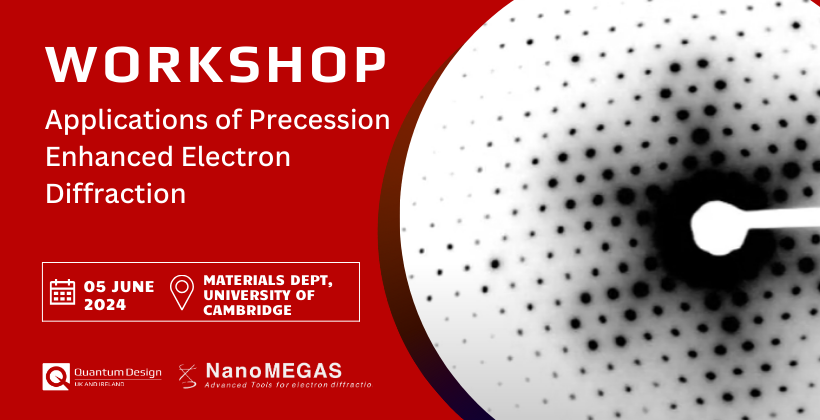

Special Event

Quantum Design and NanoMEGAS are excited to announce a special workshop celebrating the 30th anniversary of beam precession development in electron diffraction for Transmission Electron Microscopy (TEM). The event will take place 5th June, at Cambridge University, where the pioneers in beam precession technology has significant impact in the field.

Special Offers

We have a J. A. Woollam alphaSE system is available immediately for use with an educational discount. PLUS a 2 year warranty. Don’t miss this opportunity, register your interest in owning it today!

Academic discount available on the Raptor Photonics Ninox 640 SU

We’re excited to be able to offer an ex-demo InfraTec 8300 hp infrared camera for sale, complete with a 1 year warranty.

Latest News

New Team Member

Introducing our latest addition to the QDUKI team. Meet the service department and find out what they can do for you.

READ MORE

CryoComplete™ from Lake Shore Cryotronics

Everything you need to make temperature‑dependent,

low-level electrical measurements from 77 K to 500 K.

Illuminating the Process of Biomineralisation in Baby Teeth Using MicroXRF

This blog post by IXRF Systems delves into the application of microXRF in studying biomineralisation in teeth.

App Note: Correlative In-Situ AFM & SEM Analysis of Bone Collagen at the Nanoscale

Extract real 3D topography on hard to reach sample areas with subnanometer resolution and correlative SEM imaging.

We’ve made it easy for you! See all webinar recordings here